Preparation method and application of lithium-sulfur battery electrolyte solution

An electrolyte preparation, lithium-sulfur battery technology, applied in secondary batteries, circuits, electrical components, etc., can solve problems such as poor cycle stability, gaps, etc., and achieve the effects of simple preparation, low price, and cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] 0.5 M Li 2 S 8 / DOL+DME electrolyte preparation: measure 10 mL ether organic solvent DOL+DME (volume ratio 1:1), add 1120 mg elemental sulfur (35 mmol) and 230 mg lithium sulfide (5 mmol) respectively, seal and take out In a glove box, sonicate for 1 h and react at 60 °C for 3–5 h; then add 69 mg (0.1 mol) LiNO to the above electrolyte in the glove box 3 Additive, standing for 6~8 h, then get 0.5 M Li 2 S 8 / DOL+DME electrolyte.

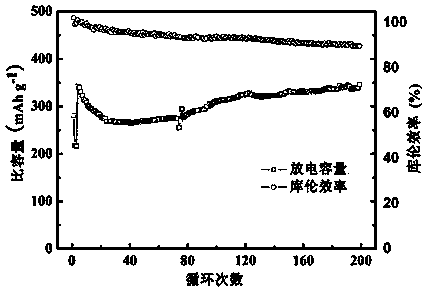

[0020] Battery assembly and testing: Evenly mix elemental sulfur, acetylene black, and binder at a mass ratio of 70:20:10, then add N-methyl-2-pyrrolidone (NMP), make a slurry, and coat it on aluminum foil. After drying, a lithium-sulfur battery cathode sheet is obtained. A lithium-sulfur battery was assembled using metallic lithium as the negative electrode, and the electrolyte was newly configured 0.5 M Li 2 S 8 / DOL+DME. The charge and discharge cut-off voltage is 1.5~3.0 V ( vs. Li / Li + ), charge-discharge cycles were performed ...

Embodiment 2

[0022] 0.5 M Li 2 S 4 / DOL+DME electrolyte preparation: Weigh 480 mg of elemental sulfur (15 mmol) and 230 mg of lithium sulfide (5 mmol) according to the stoichiometric ratio and add 10 mL of mixed ether organic solvent DOL+DME (volume ratio is 1:1) , after fully reacting, add 69 mg of LiNO 3 Additive, concrete steps are with embodiment one.

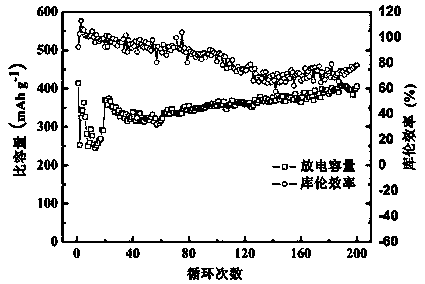

[0023] Battery assembly and testing: The preparation process of the sulfur electrode pole piece is the same as in Example 1, and the electrolyte used in battery assembly is 0.5 M Li 2 S 4 / DOL+DME. Electrochemical test conditions are the same as in Example 1. For the first time, the sulfur electrode has a specific capacity of 281 mAh g in this electrolyte -1 , after 200 cycles, its specific capacity increased to 346 mAh g -1 .

Embodiment 3

[0025] 0.5 M Li 2 S 8 / DOL+DME electrolyte deployment: the specific steps are the same as in Example 1.

[0026]Preparation of graphene / sulfur composite material: According to the mass ratio of 600 mg elemental sulfur and 400 mg graphene, fully mixed and ground, and treated at 155 °C for 12 h, the graphene / sulfur composite material was obtained.

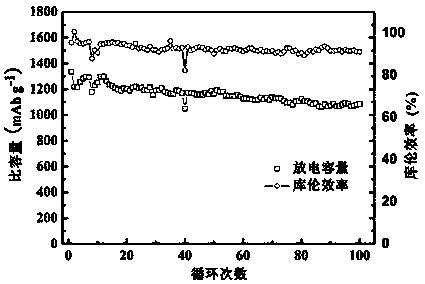

[0027] Battery assembly and testing: Evenly mix graphene / sulfur composite material, acetylene black, and binder at a mass ratio of 70:20:10, then add N-methyl-2-pyrrolidone (NMP), make a slurry, and then coat On the aluminum foil, after drying, the graphene / sulfur positive electrode sheet is obtained, and the electrolyte used for battery assembly is 0.5 M Li 2 S 8 / DOL+DME. Electrochemical test conditions are the same as in Example 1. Graphene / sulfur electrode achieves first specific capacity of 1337 mAh g in this electrolyte -1 , after 200 cycles, its specific capacity still maintains 1085 mAh g -1 , The capacity retention ra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com