Positive electrode of lithium-sulfur battery and preparation method of positive electrode

A lithium-sulfur battery and positive electrode technology, which is applied in the field of lithium-sulfur battery positive electrode manufacturing, can solve the problems of rapid capacity decay and active material loss, and achieve the effects of enhancing sulfur fixation, enhancing barrier effect, and improving cycle performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

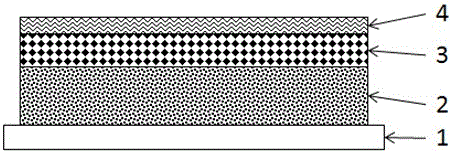

[0028] Sulfur cathode preparation:

[0029] Inner layer coating: Weigh 70g of elemental sulfur, 20g of carbon material conductive agent (including 6g of Ketjen black, 2g of mesoporous carbon, 4g of carbon nanotube, 8g of Super P), 10g of binder polyvinylidene fluoride PVDF, and N-methylpyrrolidone NMP is used as a solvent to adjust the viscosity. After stirring the slurry for 12 hours in an environment with a dew point 2 .

[0030] Intermediate layer coating: Weigh 65g of elemental sulfur, 25g of carbon material conductive agent (including 16g of Super P, 9g of carbon nanotubes), 10g of binder polyvinylidene fluoride PVDF, and use N-methylpyrrolidone NMP as a solvent to adjust the viscosity. After stirring the slurry for 12 hours in an environment with a dew point 2 .

[0031] Surface layer coating: Weigh 18g carbon material conductive agent (including 14g Super P, 4g graphene), 2g binder polyvinylidene fluoride PVDF, use N-methylpyrrolidone NMP as solvent to adjust the visco...

Embodiment 2

[0036] Sulfur cathode preparation:

[0037] Inner layer coating: Weigh 75g of elemental sulfur, 15g of carbon material conductive agent (including 4g of Ketjen black, 1.5g of mesoporous carbon, 3g of carbon nanotube, 6.5g of Super P), 10g of binder polyvinylidene fluoride PVDF , using N-methylpyrrolidone NMP as a solvent to adjust the viscosity, stirring the slurry for 12 hours at an environment with a dew point 2 .

[0038] Intermediate layer coating: Weigh 70g of elemental sulfur, 20g of carbon material conductive agent (including 13g of Super P, 7g of carbon nanotubes), 10g of binder polyvinylidene fluoride PVDF, and use N-methylpyrrolidone NMP as a solvent to adjust the viscosity. After stirring the slurry for 12 hours in an environment with a dew point 2 .

[0039] Surface layer coating: Weigh 18g carbon material conductive agent (including 14g Super P, 4g graphene), 2g binder polyvinylidene fluoride PVDF, use N-methylpyrrolidone NMP as solvent to adjust the viscosity, a...

Embodiment 3

[0044] Sulfur cathode preparation:

[0045] Inner layer coating: Weigh 60g of elemental sulfur, 30g of carbon material conductive agent (including 8g of Ketjen black, 4g of mesoporous carbon, 6g of carbon nanotube, 12g of Super P), 10g of binder polyvinylidene fluoride PVDF, and N-methylpyrrolidone NMP is used as a solvent to adjust the viscosity. After stirring the slurry for 12 hours in an environment with a dew point 2 .

[0046] Intermediate layer coating: Weigh 55g of elemental sulfur, 35g of carbon material conductive agent (including 23g of Super P, 12g of carbon nanotubes), 10g of binder polyvinylidene fluoride PVDF, and use N-methylpyrrolidone NMP as a solvent to adjust the viscosity. After stirring the slurry for 12 hours in an environment with a dew point 2 .

[0047] Surface layer coating: Weigh 18g carbon material conductive agent (including 14g Super P, 4g graphene), 2g binder polyvinylidene fluoride PVDF, use N-methylpyrrolidone NMP as solvent to adjust the vis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com