Positive pole composite system of lithium sulphur battery containing catalytic additive

A lithium-sulfur battery and additive technology, applied in the field of electrochemistry, can solve problems such as unfavorable large-scale production and commercial application, complex preparation process of special structure carbon materials or conductive polymers, and structural damage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0077] The present invention also provides a method for preparing the positive electrode, which includes the following steps:

[0078] Add the required active substances, inorganic nano-additives, and conductive agents into the solvent, and obtain a uniform dispersion through treatment;

[0079] The dispersion liquid is heated and evaporated to dryness in a water bath to obtain a uniformly dispersed solid powder material.

[0080] In a preferred embodiment, the solvent is selected from the group consisting of water, ethanol, acetone, butanone, carbon disulfide, carbon tetrachloride, benzene, toluene, xylene, and NMP.

[0081] When preparing the positive electrode, put an appropriate amount of electrode material in a solvent, stir evenly to form a slurry, coat it on the current collector electrode such as aluminum foil, dry, roll and cut to obtain the positive electrode sheet of the lithium-sulfur battery. Preferably, the positive electrode slurry has a solid content of 0.01g / ...

Embodiment approach

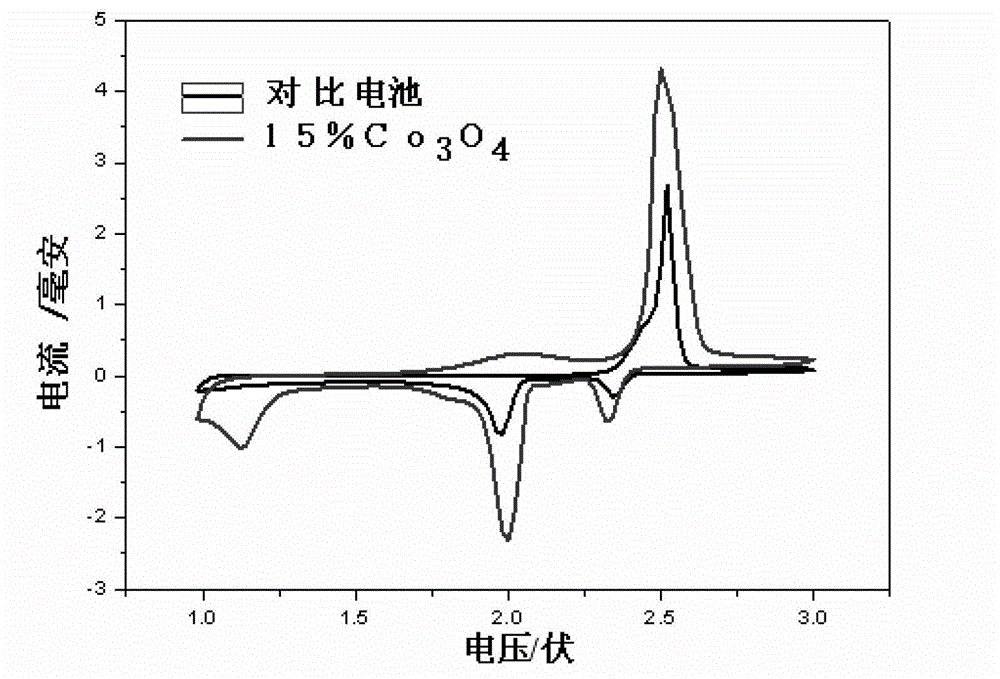

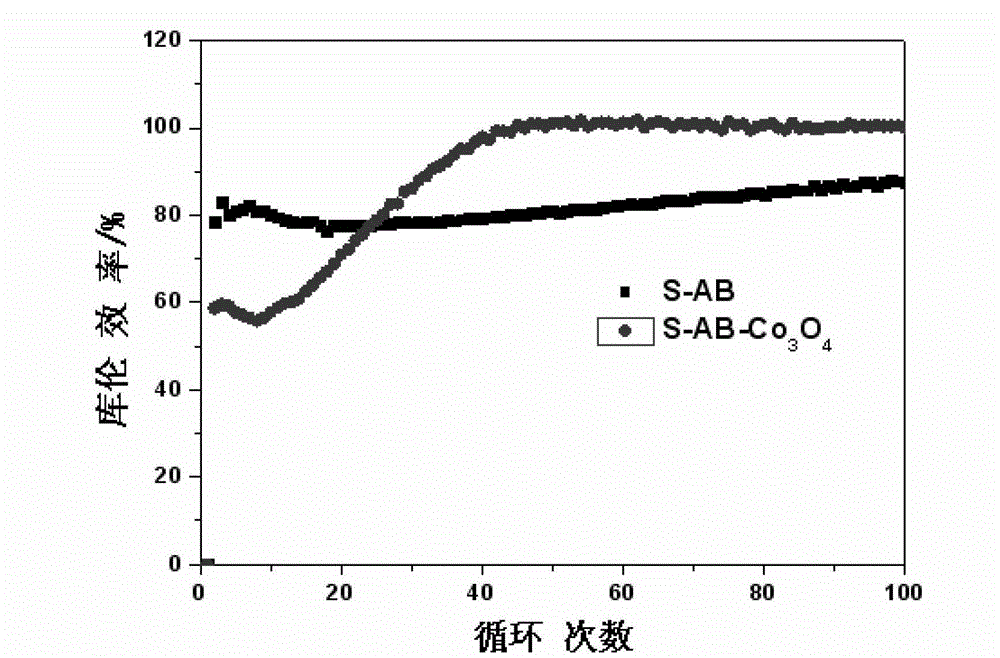

[0095] The present invention designs an inorganic nano-compound with catalytic activity as a sulfur positive electrode additive. The inorganic nano-additive has a catalytic effect on the lithium-sulfur battery reaction, reduces the activation energy of the reaction, and improves the reversibility of the battery reaction. Therefore, the coulombic efficiency of the battery can be improved, and the discharge ratio of the battery can be improved. capacity and battery cycle performance. At the same time, additives can be adsorbed on sulfur and polysulfides generated in the battery reaction, which can improve the dispersion of sulfur and inhibit the shuttle effect; oxide additives can increase the specific surface area and pore volume of the electrode, improve the contact between the electrode and the electrolyte, and reduce Battery resistance; In short, oxide additives can significantly improve battery performance and prolong battery life.

[0096] The disadvantages of low sulfur u...

Embodiment 1

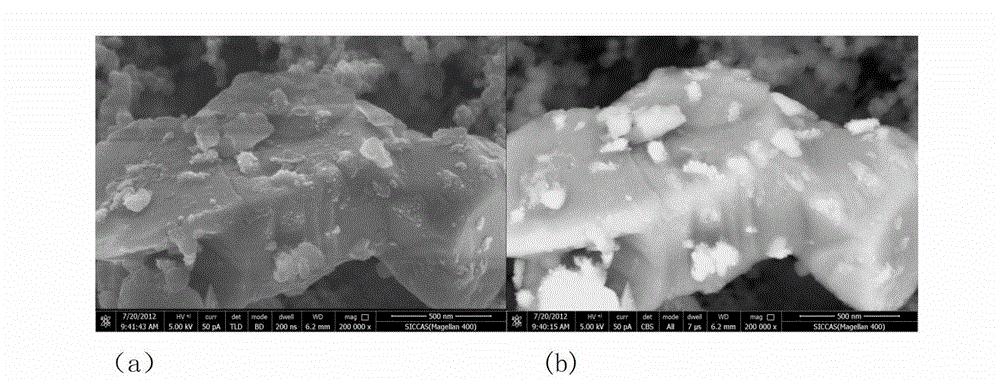

[0115] Co 3 o 4 As an additive, it is added to the positive electrode of lithium-sulfur battery by ultrasonic mixing method to obtain the following figure 1 The microstructure shown, Co 3 o 4 adsorbed on the surface of S. The additive content is 10%, the positive electrode active material is sulfur, the content is 25%, acetylene black is the conductive agent, the content is 45%, and 20% polyvinylidene fluoride solution (solvent is N-methylpyrrolidone) is used as the bond The positive electrode slurry was prepared by using the same agent, and then the slurry was uniformly coated on the aluminum foil, and dried to obtain the electrode film.

[0116] Cut the obtained electrode membrane into 14mm discs directly, use metal lithium as the negative electrode, Celgard membrane as the separator, and the electrolyte as 1MLiTFSI (lithium bistrifluoromethanesulfonimide) DOL (1,3-dioxolane ring) / TEGDME(1 / 1, v / v). The assembly of the entire battery is done in a glove box.

[0117] Ad...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com