Positive electrode material for lithium-sulfur battery and preparation method for positive electrode material

A cathode material, a technology for lithium-sulfur batteries, applied in battery electrodes, secondary batteries, circuits, etc., can solve problems such as the inability to effectively inhibit lithium polysulfide dissolution from lithium polysulfide flying shuttle effect, etc., to improve capacity and cycle times, preparation The method is simple and the effect of suppressing the shuttle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

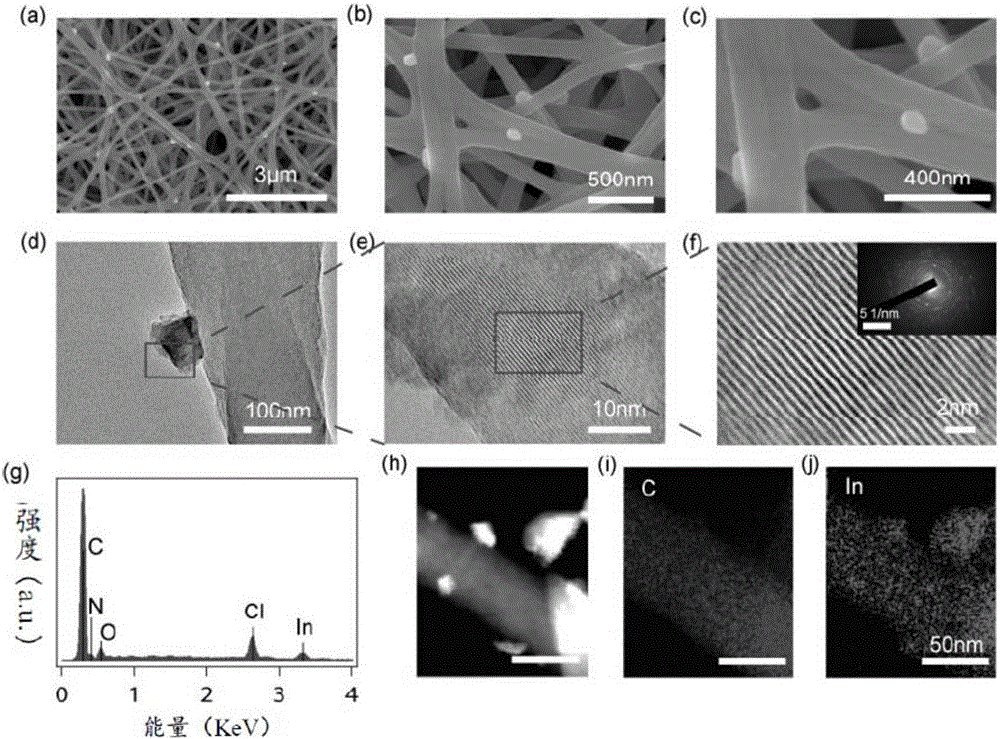

[0055] (1) Dissolve 0.5g of polyacrylonitrile (PAN, Mw=150,000) and 0.5g of polyvinylpyrrolidone (PVP, Mw=1,300,000) in 10ml of dimethylformamide (DMF), and stir at 60°C for 12h to obtain spinning Silk liquid, transfer it into a syringe, place it on the syringe pump, and place a piece of conductive carbon 18 cm opposite to serve as the electrospinning receiver. Connect the high voltage power supply to the syringe needle and the ground wire to the conductive carbon. Apply high voltage of 15kV, the flow rate of the syringe pump is 0.3ml h -1 , After collecting for 4 hours, a polyacrylonitrile / polyvinylpyrrolidone / dimethylformamide composite fiber film was obtained.

[0056] (2) The composite fiber film obtained in step (1) is placed in a muffle furnace, and calcined at 300° C. for 4 hours, and the heating rate is 5-10° C. / min. The polyvinylpyrrolidone shell will be burned away, leaving an oxidized free-standing polyacrylonitrile oxide film.

[0057] (3) Place the independentl...

Embodiment 2

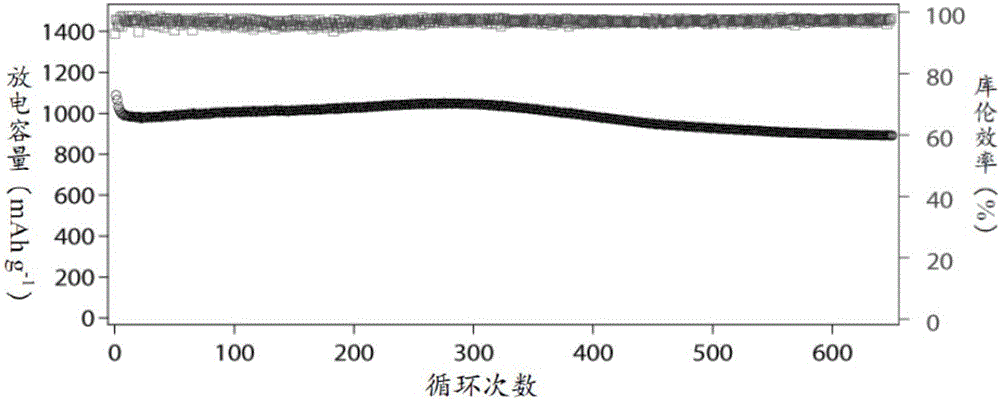

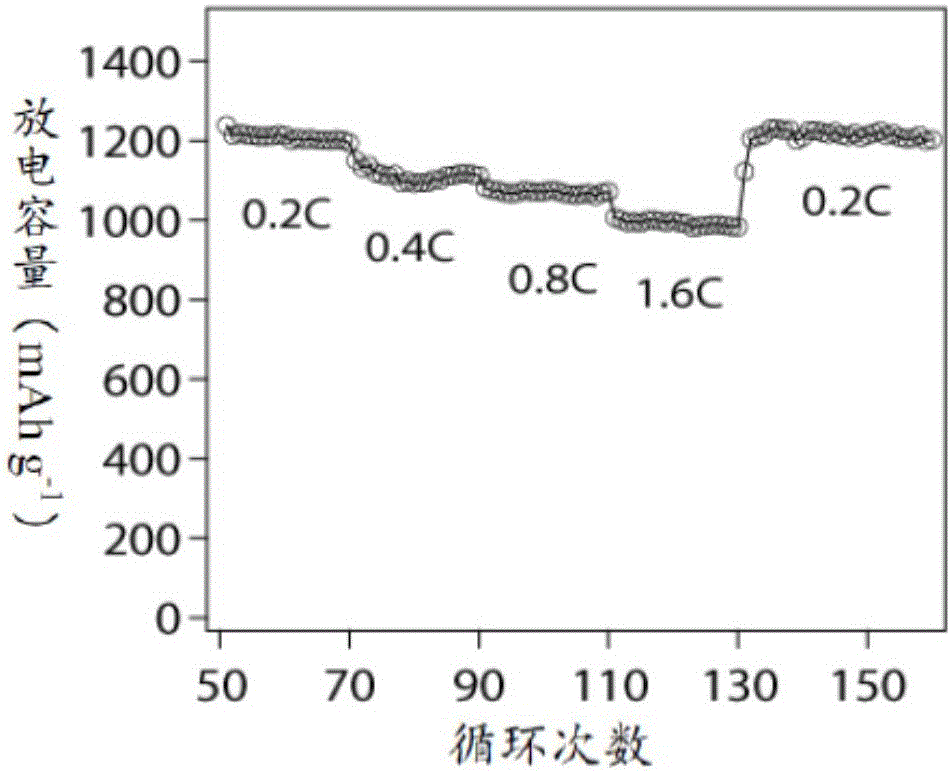

[0062] Using the same preparation process as in Example 1, the only difference is that in step (5), under argon protection, 12.5 μl of 5mol / L Li 2 S 8 - The DOL / DME solution was dropped onto the substrate and dried under argon to obtain a S loading of 2 mg / cm 2 positive electrode material.

[0063] The positive electrode material prepared in this example is the positive electrode of a lithium-sulfur battery, and the lithium-sulfur battery is assembled with reference to the raw materials and processes in Example 1. For performance, see image 3 and Figure 4 .

Embodiment 3

[0065] (1) Dissolve 0.9g of polyacrylonitrile (PAN, Mw=150,000) and 0.1g of polyvinylpyrrolidone (PVP, Mw=1,300,000) in 10ml of dimethylformamide (DMF), and stir at 60°C for 12h to obtain spinning Silk liquid, transfer it into a syringe, place it on the syringe pump, and place a piece of conductive carbon 20 cm opposite to serve as the electrospinning receiver. Connect the high voltage power supply to the syringe needle and the ground wire to the conductive carbon. Apply 25kV high voltage, the flow rate of the syringe pump is 1.0ml h -1 , After collecting for 4 hours, a polyacrylonitrile / polyvinylpyrrolidone / dimethylformamide composite fiber film was obtained.

[0066] (2) The composite fiber film obtained in step (1) is placed in a muffle furnace, and calcined at 320° C. for 2 hours, and the heating rate is 5-10° C. / min. The polyvinylpyrrolidone shell will be burned away, leaving an oxidized free-standing polyacrylonitrile oxide film.

[0067] (3) Place the independently f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com