Additive-free sulfonated graphene/sulfur electrode slice and preparation method and application thereof

A technology of sulfonated graphene and sulfonated graphene, which is applied in battery electrodes, non-aqueous electrolyte battery electrodes, circuits, etc., can solve the problems of reducing electronic conductivity and destroying conjugated structures, and achieves good reproducibility and material The effect of uniform structure distribution and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

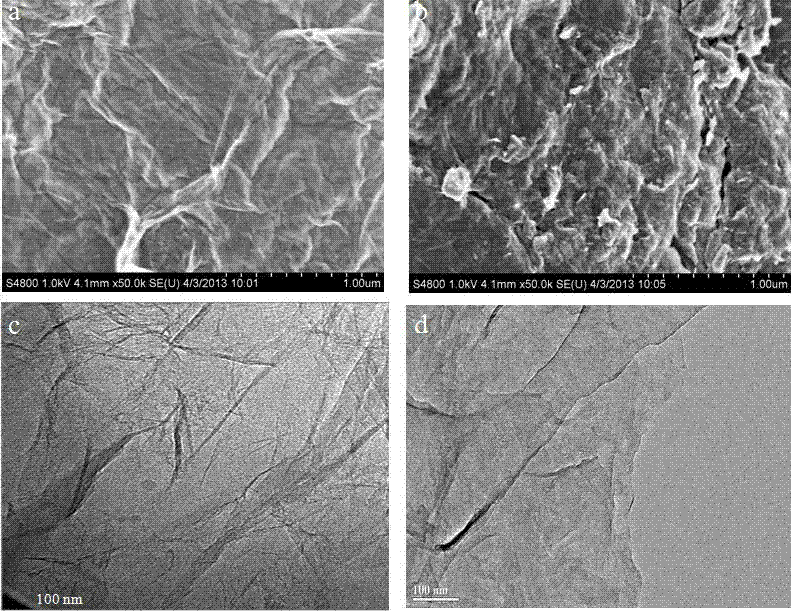

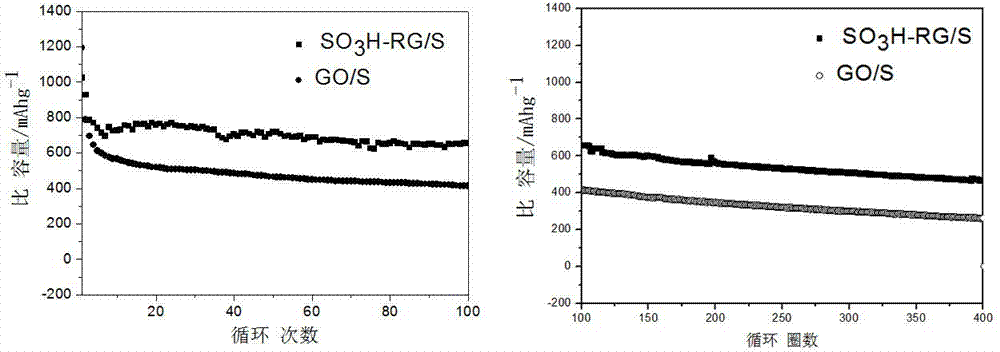

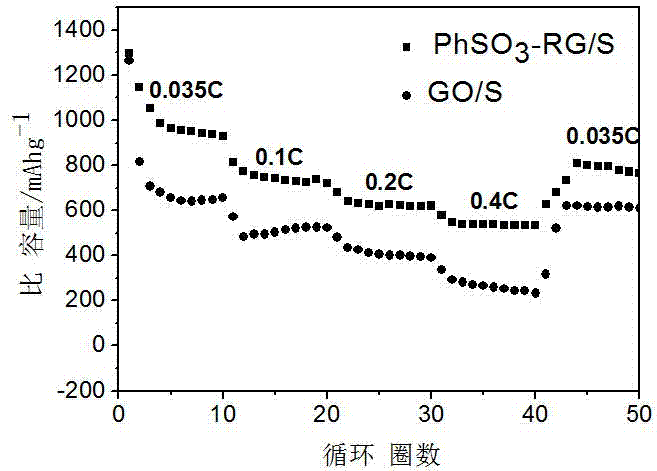

Image

Examples

Embodiment 1

[0022] 1. The synthesis steps of acidified graphene are as follows: disperse 300-400 mg graphene oxide in 300-400 ml deionized water, and sonicate for 2-3 h. It can be obtained after three processes of pretreatment, sulfonation and posttreatment. in:

[0023] The pretreatment process is as follows: use 5%-10% sodium carbonate solution to adjust the pH of the graphene oxide dispersion described in a to 9-10, and then add 75-100 ml of 0.03-0.04 g / ml sodium borohydride solution , the above mixed solution was stirred at 80-100 ℃ for 3-4 h, then centrifuged, washed with a large amount of water until neutral, and the partially reduced graphene oxide product was obtained, and the product was redispersed in 30-40 ml deionized water, ultrasonically 2-3h.

[0024] The sulfonation process is as follows: first, diazonium benzenesulfonate is prepared. In a 100 ml beaker, add 0.8-1.2 g p-aminobenzenesulfonic acid crystals, add 8-12 ml 2%-5% NaOH solution, dissolve it in a hot water bath,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com