Sulfur-porous carbon felt composite positive material for lithium battery

A technology of composite positive electrode material and carbon felt, which is applied to battery electrodes, lithium storage batteries, non-aqueous electrolyte storage batteries, etc., can solve the problems of loss of cycle performance of active materials, complicated preparation methods, and high cost, and achieves maintenance of cycle performance and simple preparation methods. , to achieve the effect of mass production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Weigh 5g of sulfur powder into a 100mL zirconia ball mill jar, then add 20mL of ethanol (>99.7%, analytically pure), and mill at 500 rpm for 2 hours; then drop the obtained sulfur-containing slurry onto 5g of activated carbon felt ( Produced by Qingdao Huashijie Environmental Protection Technology Co., Ltd., 30mg / cm 2 ), vacuum drying at 58oC for 14h; the obtained composite felt was compacted, and then heat-treated in a muffle furnace at 152oC for 14h to obtain a sulfur-activated carbon felt composite cathode material (prepared by infiltration and heat treatment), with a sulfur content of 48.6%.

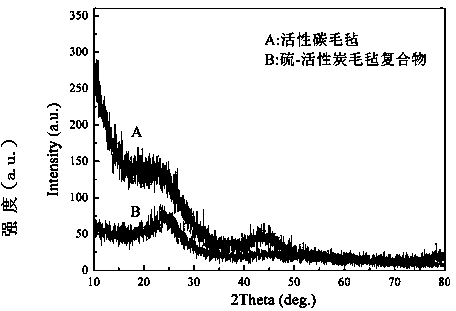

[0026] Such as figure 1 As shown, there is no obvious change in its XRD spectrum before and after compounding with sulfur.

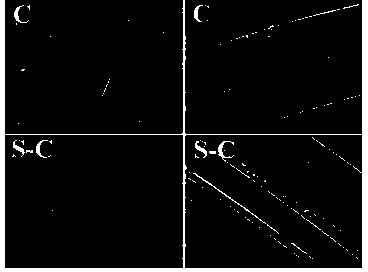

[0027] Such as figure 2 As shown, before and after compounding with sulfur, the overall morphology has no obvious change, and it is a conductive carbon network formed by the cross-linking of activated carbon fibers, but there is obvious sulfur on the ...

Embodiment 2

[0029] The sulfur-activated carbon felt composite cathode material obtained above is punched into 50mm 2 The disc is the positive electrode, and the sulfur loading is 14.2mg. Lithium metal is the negative electrode, and the electrolyte is 1mol / L LiN(CF 3 SO 2 ) 2 solution (0.2mol / L lithium nitrate), the solvent is a mixture of dioxolane and dimethoxyethane in a volume ratio of 1:1. Assemble the battery in the glove box.

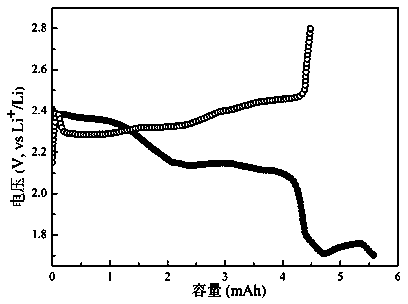

[0030] The charge and discharge research of the installed battery is carried out at room temperature, and the charge and discharge voltage range is: 1.7V~2.8V. Such as image 3 As shown, at a current density of 80mA / g (calculated according to sulfur), its reversible charge capacity is 4.48mAh, and its surface capacity reaches 8.96mAh / cm 2 .

Embodiment 3

[0032] Weigh 15g of elemental sulfur and dissolve it in 50mL of carbon disulfide solution, and then apply 3g of activated carbon felt (Qingdao Huashijie Environmental Protection Technology Co., Ltd., 10mg / cm 2 ) into the prepared carbon disulfide solution of sulfur and soaked for 6 hours, took it out and placed it in a fume hood for 14 hours, and then dried it in vacuum at 58oC for 15 hours to obtain the sulfur-activated carbon felt composite positive electrode material (prepared by solution infiltration and infiltration method), containing sulfur The amount is 38.9%. .

[0033] The sulfur-activated carbon felt composite cathode material obtained above is punched into 50mm 2 The disc is the positive electrode, and the weight of the entire pole piece is 8mg. Lithium metal is the negative electrode, and the electrolyte is 1mol / L LiN(CF 3 SO 2 ) 2 solution (0.2mol / L lithium nitrate), the solvent is a mixture of dioxolane and dimethoxyethane in a volume ratio of 1:1. Assembl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Reversible charge capacity | aaaaa | aaaaa |

| Surface capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com