A kind of natural water-based sulfur positive electrode binder and its preparation method and its application in the preparation of lithium-sulfur battery sulfur positive electrode

A lithium-sulfur battery and sulfur cathode technology, applied in non-aqueous electrolyte battery electrodes, battery electrodes, lithium batteries, etc., can solve the problems of high pollution, poor polysulfide affinity, poor mechanical properties, etc., and meet low equipment requirements. , the effect of improving cycle stability and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

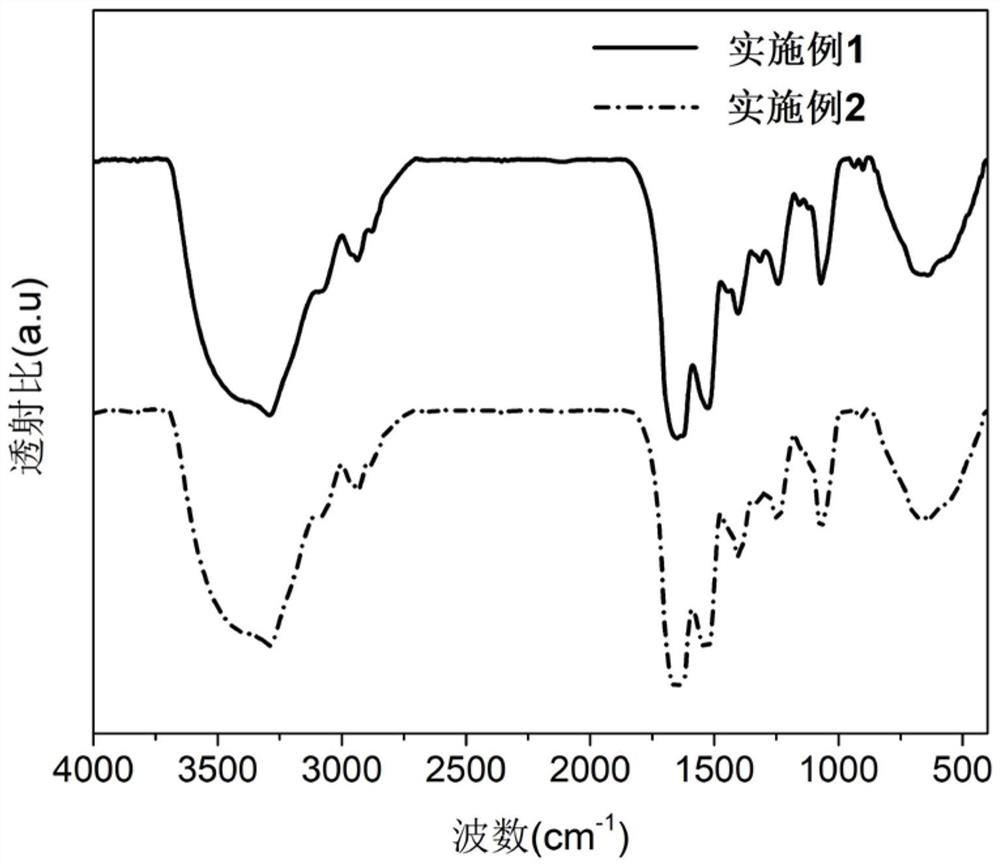

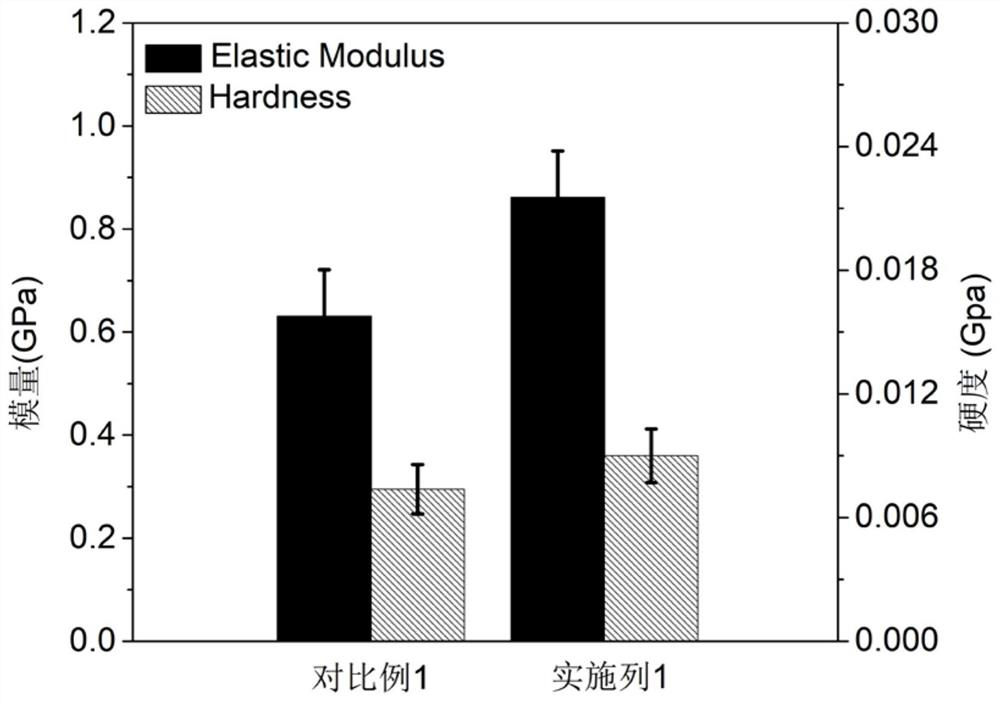

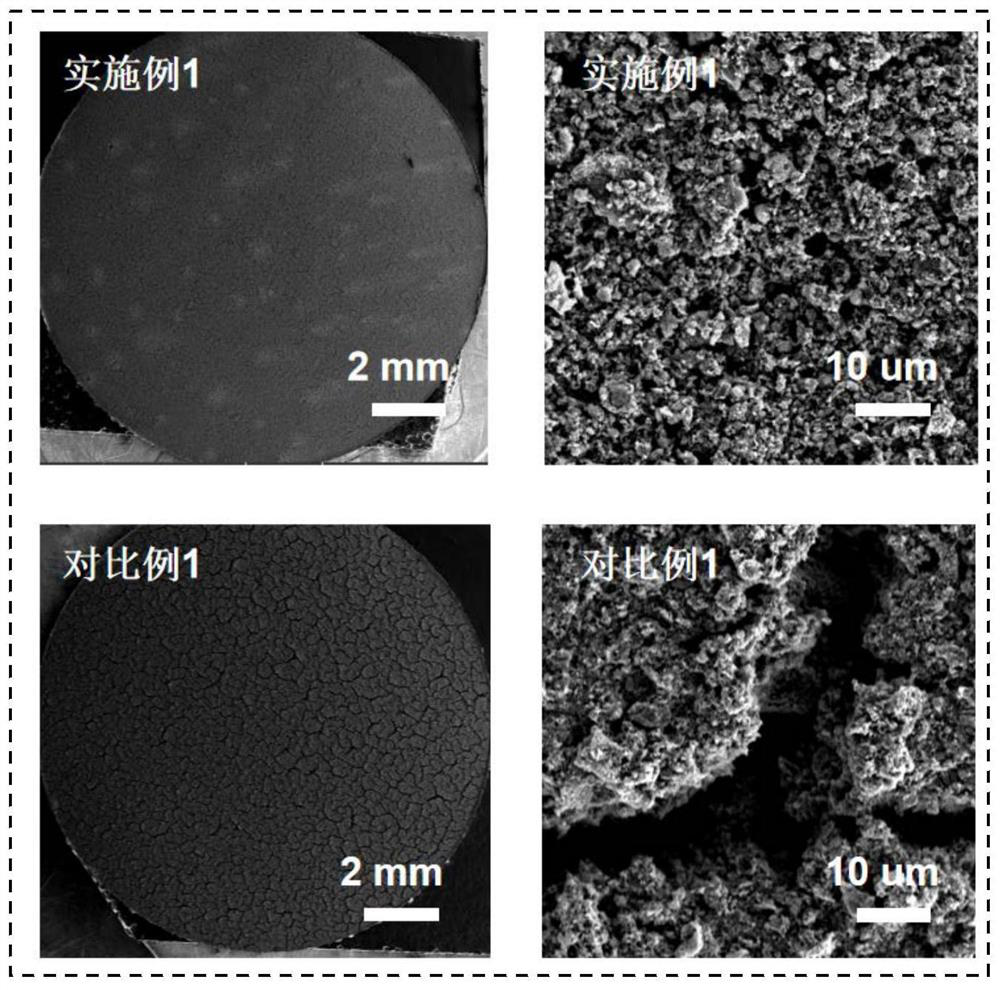

Embodiment 1

[0041] A preparation method of natural water-based sulfur cathode binder, comprising the following steps:

[0042] (1) Cut the natural silkworm cocoons into small pieces, sonicate them with deionized water and absolute ethanol for 20 minutes, and then dry them at 60°C for later use to obtain the pretreated silkworm cocoons;

[0043] (2) Disperse the pretreated cocoons in step (1) in ultrapure water, the mass ratio of cocoons to water is 1:80, heat for 2 h at 95°C, during the heating period, every 10 min Fully stir the solution with a glass rod;

[0044] (3) After the solution obtained in step (2) is cooled, use gauze (pore size 80 mesh) to filter out large insoluble impurities, and then perform centrifugation. The speed of the centrifuge is 9000 r / min, centrifuge twice , and centrifuged for 3 min each time to remove suspended small particle impurities and obtain a clear and transparent supernatant;

[0045] (4) Selecting a dialysis bag with a molecular weight cut-off of 10,0...

Embodiment 2

[0052] A preparation method of natural water-based sulfur cathode binder, comprising the following steps:

[0053] (1) Cut the natural silkworm cocoons into pieces, ultrasonicate them with deionized water and absolute ethanol for 25 minutes, and then dry them at 60°C for later use to obtain the pretreated silkworm cocoons;

[0054] (2) Disperse the silkworm cocoons pretreated in step (1) in ultrapure water, the mass ratio of silkworm cocoons to water is 1:150, heat for 4 hours at 90°C, and use a glass rod every 15 minutes Thoroughly stir the solution;

[0055] (3) After the solution obtained in step (2) is cooled, use gauze (pore size of 100 mesh) to filter out large insoluble impurities, and then perform centrifugation. The speed of the centrifuge is 7000 r / min, centrifuge 3 times , and centrifuged for 2 min each time to remove suspended small particle impurities and obtain a clear and transparent supernatant;

[0056] (4) Select a dialysis bag with a molecular weight cut-o...

Embodiment 3

[0063] A preparation method of natural water-based sulfur cathode binder, comprising the following steps:

[0064] (1) Cut the natural silkworm cocoons into pieces, ultrasonicate them with deionized water and absolute ethanol for 30 minutes, and then dry them at 60°C for later use to obtain the pretreated silkworm cocoons;

[0065] (2) Disperse the pretreated cocoons in step (1) in ultrapure water, the mass ratio of cocoons to water is 1:120, heat for 3 hours at 85°C, during the heating period, every 20 minutes Fully stir the solution with a glass rod;

[0066] (3) After the solution obtained in step (2) is cooled, use gauze (pore size: 120 mesh) to filter out large insoluble impurities, and then perform centrifugation. The speed of the centrifuge is 10,000 r / min, centrifuge twice , and centrifuged for 1 min each time to remove suspended small particle impurities and obtain a clear and transparent supernatant;

[0067] (4) Select a dialysis bag with a molecular weight cut-of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| modulus | aaaaa | aaaaa |

| current efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com