All-solid-state battery cell structure, preparation method thereof and all-solid-state battery cell group

An all-solid-state, cell technology, applied in the manufacturing of structural parts, battery electrodes, electrolyte batteries, etc., can solve the problems of poor cycle life, reduced battery capacity, low conductivity of silicon materials, etc., to improve manufacturing efficiency and consistency, The effect of increasing cycle performance and simplifying the preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

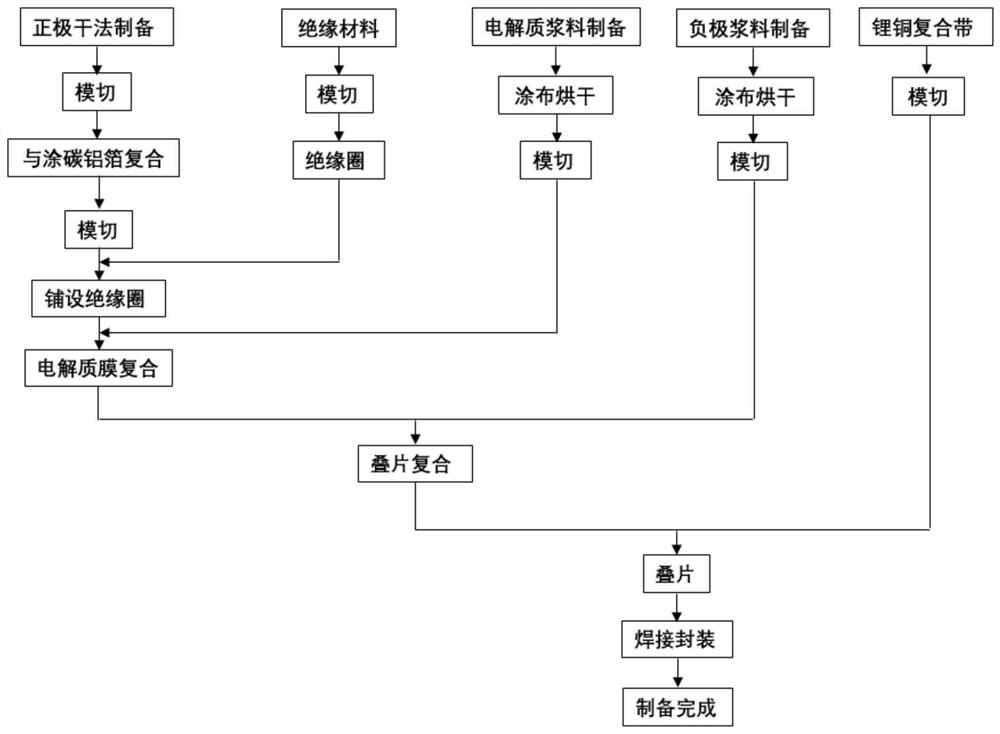

[0115] This embodiment provides a method for preparing an all-solid battery structure, such as figure 1 Shown, described preparation method comprises:

[0116] (1) Take NCM811@Li 2 TiO 3 (NCM811 cathode particles are coated with 5nm thick Li 2 TiO 3 ) is the positive active material, Li 6 P.S. 5 Cl is the positive electrode electrolyte, CNT is the conductive agent, and PTFE is the positive electrode binder. They are mixed according to the mass ratio of 85:12:2:1, followed by ball milling, mixing and grinding, and hot rolling to 88 μm to obtain the positive electrode active layer 6 (Such as figure 2 shown), die-cut into 90×180mm sheets (such as image 3 shown); the die-cut positive electrode active layer 6 and the carbon-coated aluminum foil 7 are roll-combined (such as Figure 4 shown), die-cut again to obtain a positive electrode sheet into a thin sheet of 93×183 mm, and when die-cutting, the outer edge of the positive electrode active layer 6 retains a carbon-coated...

Embodiment 2

[0128] This embodiment provides a method for preparing an all-solid-state battery structure, the preparation method comprising:

[0129] (1) Take NCM811@LiNbO 3 (NCM811 cathode particles are coated with 1 nm thick LiNbO 3 ) is the positive active material, Li 10 GeP 2 S 12 It is the positive electrode electrolyte, conductive carbon black is the conductive agent, and PTFE is the positive electrode binder. They are mixed according to the mass ratio of 40:40:10:10, and are mixed and ground by ball milling in turn, and then hot rolled to 88 μm to obtain the positive electrode active layer. 6. Die-cut into a sheet of 90×180 mm; roll the die-cut positive active layer 6 and carbon-coated aluminum foil 7 into a composite, die-cut again into a sheet of 93×183 mm to obtain a positive electrode sheet, when die-cutting, the positive active layer 6 The carbon-coated aluminum foil 7 with a width of 1.5mm is reserved on the outer edge, and the empty foil area of the carbon-coated alumi...

Embodiment 3

[0139] This embodiment provides a method for preparing an all-solid-state battery structure, the preparation method comprising:

[0140](1) Take NCM811@Li 2 ZrO 3 (NCM811 cathode particles are coated with 3nm thick Li 2 ZrO 3 ) is the positive active material, Li 10 SnP 2 S 12 It is the positive electrode electrolyte, carbon fiber is the conductive agent, and PTFE is the positive electrode binder. They are mixed according to the mass ratio of 50:40:5:5, and are mixed and ground by ball milling sequentially, and then hot rolled to 88 μm to obtain the positive electrode active layer 6. Die-cut into a sheet of 90×180 mm; roll the die-cut positive active layer 6 and carbon-coated aluminum foil 7 into a composite, die-cut again into a thin sheet of 93×183 mm to obtain a positive electrode sheet, and when die-cutting, the outer edge of the positive active layer 6 Reserve the carbon-coated aluminum foil 7 with a width of 2mm, and die-cut the empty foil area of the carbon-coat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com