A kind of lithium ion battery negative pole preparation method, negative pole and lithium ion battery

A lithium-ion battery and negative electrode technology, which is applied to battery electrodes, negative electrodes, secondary batteries, etc., can solve the problems of silicon-based negative electrode material current collectors falling off, reduce the use of current collectors, simplify the preparation process, and provide effective content Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

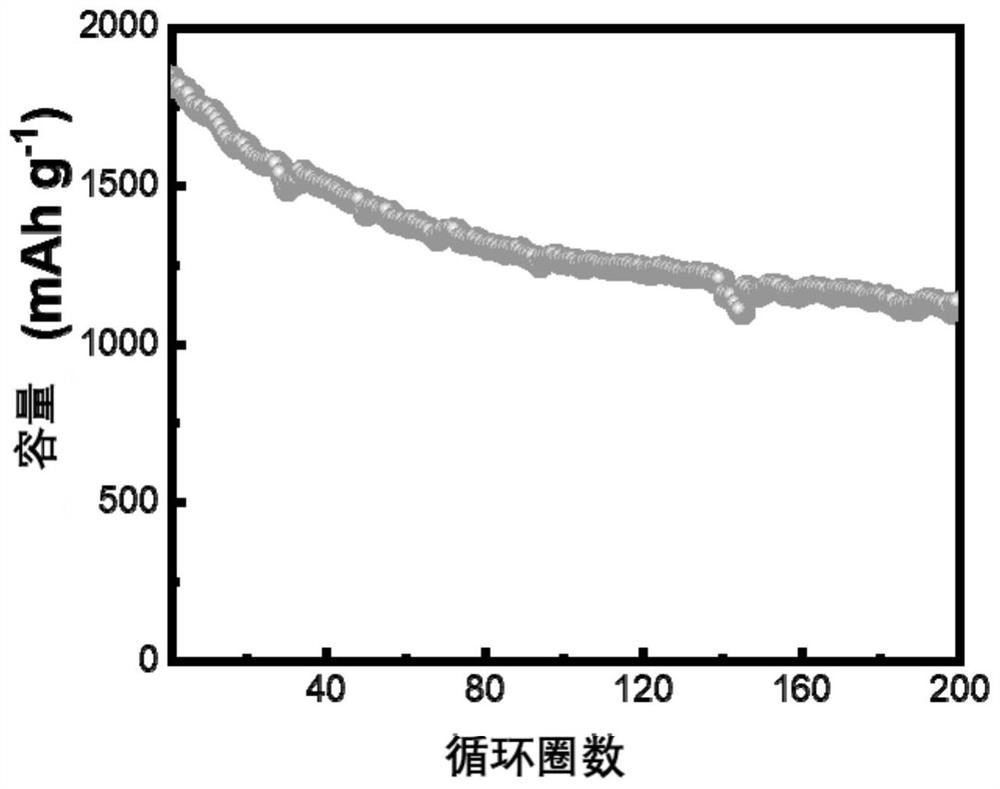

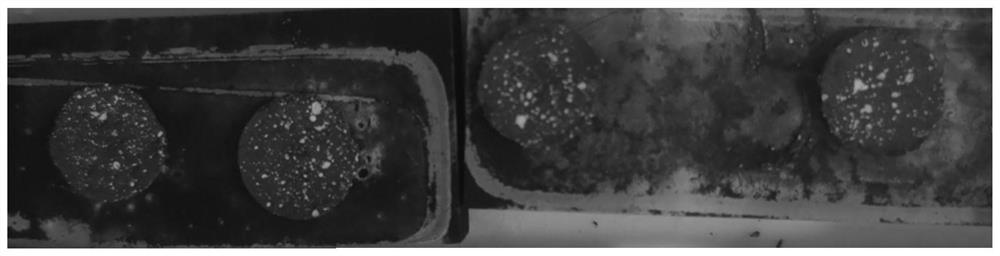

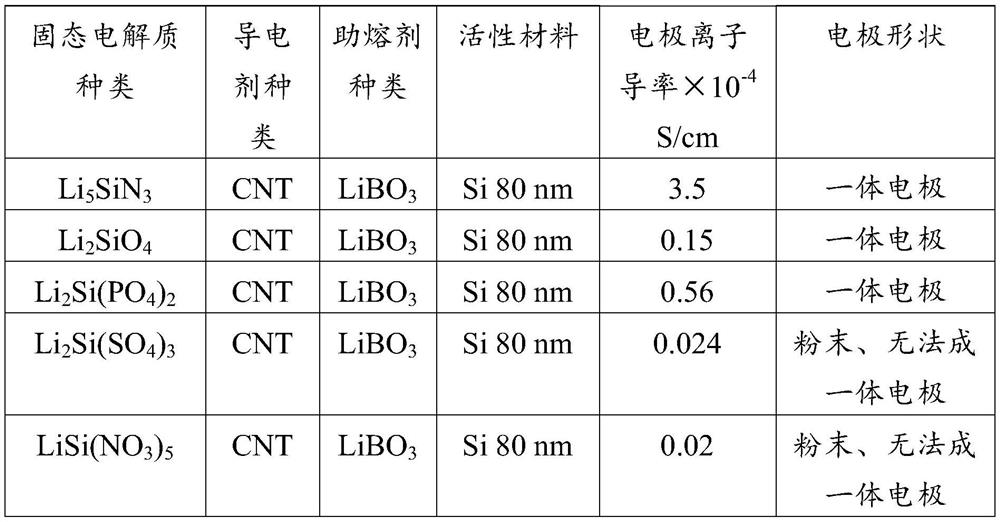

[0063] In order to find a suitable Si-containing solid electrolyte, for a variety of Si-containing solid electrolytes listed in Table 1: Li 5 SiN 3 , Li 2 SiO 4 , Li 2 Si(PO 4 ) 2 , Li 2 Si(SO 4 ) 3 , LiSi(NO 3 ) 5 Experiments were carried out, and the electrode ionic conductivity was tested, and the shape of the electrode was recorded. As shown in Table 1, when using Li 2 Si(SO 4 ) 3 , LiSi(NO 3 ) 5 When used as a solid electrolyte, the prepared electrode cannot be integrated into an electrode, and is in the form of powder, and the electrode ionic conductivity is also very low. When using Li 2 SiO 4 , Li 2 Si(PO 4 ) 2 When it is a solid electrolyte, although an integrated electrode can be obtained, the ionic conductivity of the electrode is also low. When using Li 5 SiN 3 When used as a solid electrolyte, not only an integrated electrode can be obtained, but also has excellent motor ion conduction, is stable in the air, has a small interface impedance w...

Embodiment 2

[0067] For Li x Si y N z This type of solid electrolyte, as shown in Table 2, shows that when the value of x / y is between 0.2-8 and the value of y / z is 0.1-0.8, the lithium ion conductivity of the prepared electrode is relatively high. It is relatively stable in air. It can be seen that when choosing this type of Li x Si y N z Solid electrolytes are more conducive to the performance of materials.

[0068] Table 2

[0069]

Embodiment 3

[0071] Table 3 studies different fluxes, such as lithium borate, sodium silicate, potassium silicate, cryolite, and calcium oxide. It is found that lithium borate is the preferred flux, and the prepared motor has an integrated morphology electrode, and the electrode High conductivity. When lithium borate is used as a flux, it can achieve the technical effects of increasing the lithium ion conductivity, lowering the melting point better, and improving the cycle stability of the electrode. The reason may be that it is also a solid electrolyte with a certain lithium ion conductivity. In addition, research has found that lithium borate can bind active materials very firmly, and can also effectively inhibit the volume expansion of silicon, thereby improving integration. Cycling stability of silicon-based anodes.

[0072] table 3

[0073]

[0074]

PUM

| Property | Measurement | Unit |

|---|---|---|

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com