Stereo braiding-based carbon sulfur composite electrode for sodium sulfur battery

A composite electrode, carbon-sulfur composite technology, applied in battery electrodes, active material electrodes, electrode carriers/current collectors, etc., can solve the problems of slow diffusion, electrolyte damage, blocking sodium ion transmission, etc., to achieve high battery power density, The effect of high energy efficiency and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

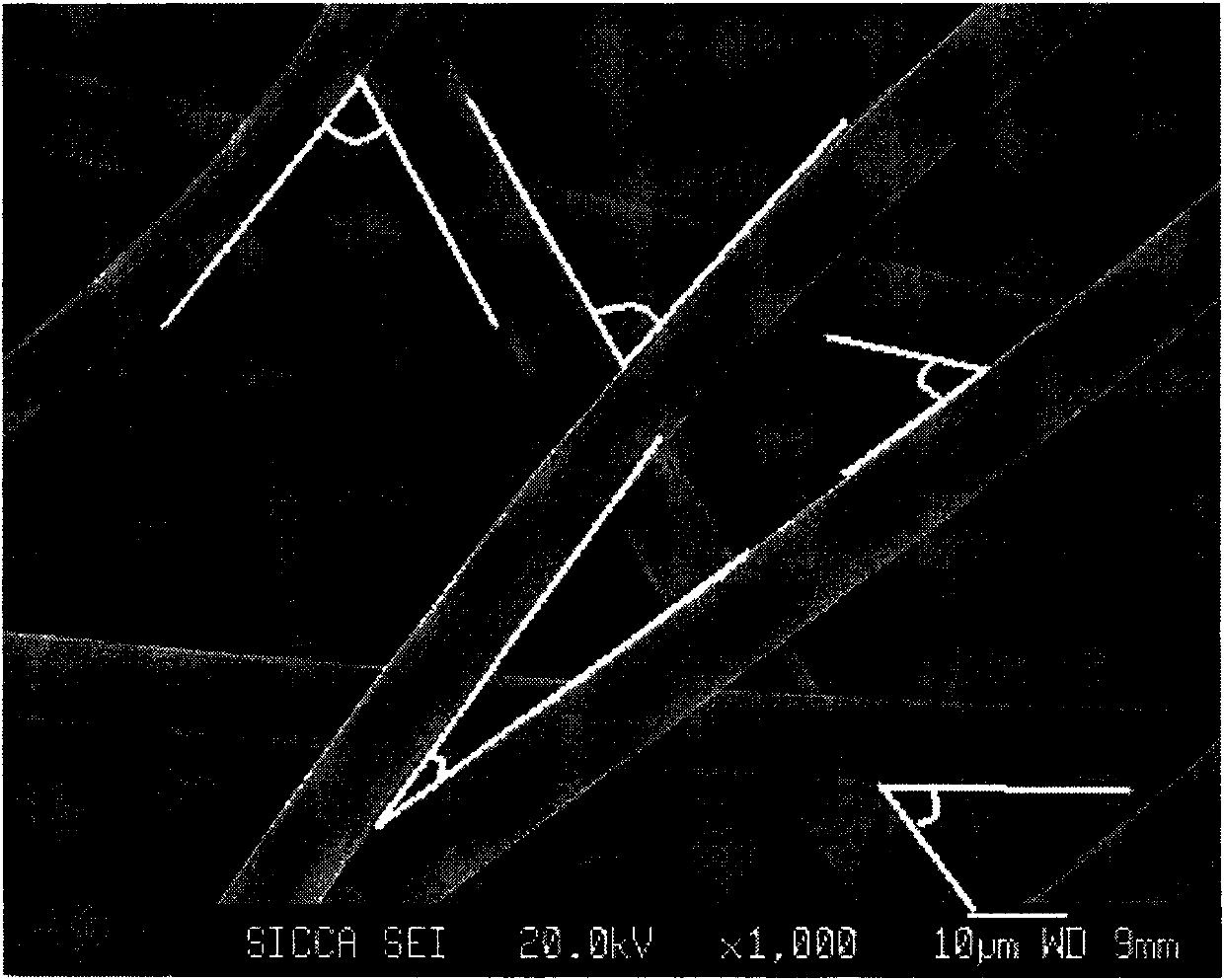

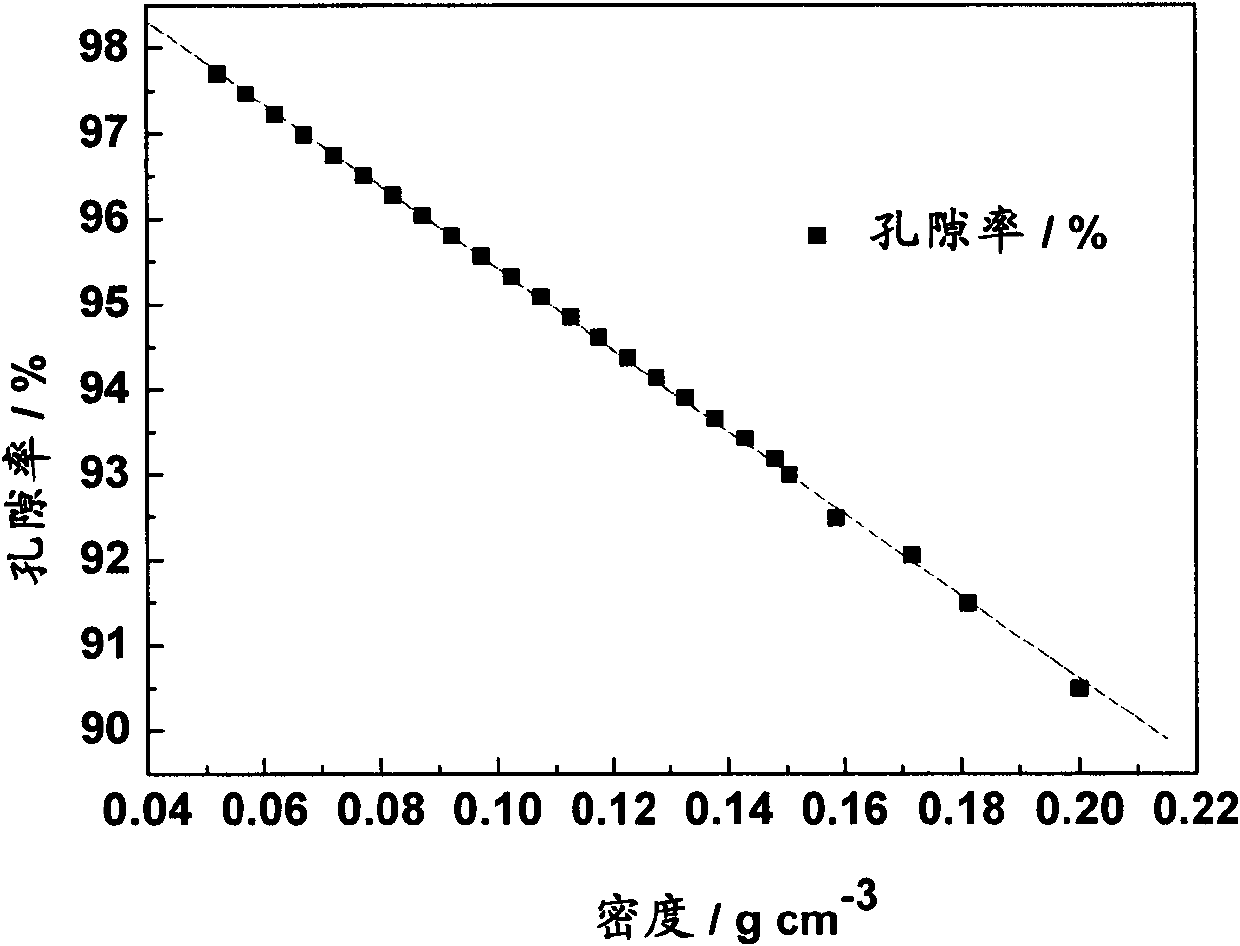

[0021] Different types of graphite felt are used to weave different angles and sulfur to make a composite sulfur electrode, with sodium as the negative electrode, β”-Al 2 o 3 Ceramics are used as electrolyte and separator to assemble a sodium-sulfur battery for testing, and compared with the composite sulfur electrode prepared by non-stereo-woven carbon felt, the implementation results are as follows:

[0022]

[0023]

[0024] The results of the examples show that the polarization of the modified sulfur electrode of the present invention is small, the internal resistance of the sodium-sulfur battery is small (compared with the comparative example, an order of magnitude smaller), and the discharge voltage, power density, and energy efficiency are all high. It has a long service life and can be made into a high-power sodium-sulfur battery.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com