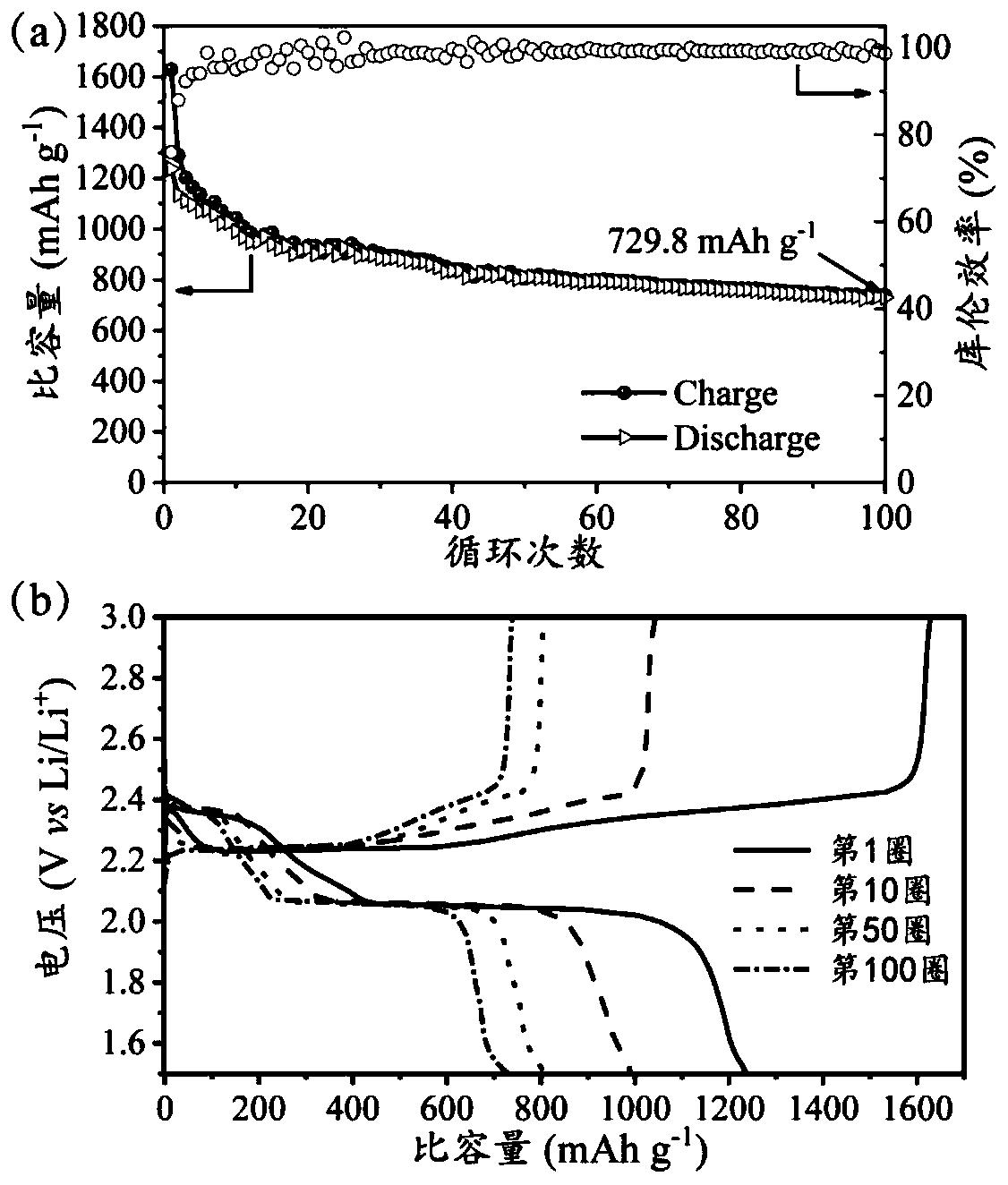

Preparation method of composite lithium-sulfur battery electrode material with three-dimensional conduction core-shell structure

A core-shell structure and electrode material technology, applied in battery electrodes, lithium batteries, positive electrodes, etc., can solve the problems of shuttle effect and low conductivity of sulfur electrode materials, and achieve good cycle performance, excellent specific capacity, and high Coulombic efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The technical solution adopted by the present invention will be further described below in combination with schematic diagrams.

[0022] A preparation method of a composite lithium-sulfur battery electrode material with a three-dimensional conductive core-shell structure (a preparation method of a three-dimensional conductive core-shell structure carbon@carbon fiber / sulfur composite lithium-sulfur battery electrode material), which dissolves polyacrylonitrile in N , N-dimethylformamide solvent to prepare the precursor sheath liquid; dissolve iron disulfide particles and polyvinylpyrrolidone in N, N-dimethylformamide solvent respectively, stir and ultrasonically, mix and stir the two into precursor core fluid. The precursor fiber was obtained by coaxial electrospinning method, followed by high-temperature carbonization treatment and one-step chemical reaction to prepare a carbon@carbon fiber / sulfur composite lithium-sulfur battery electrode material with a three-dimensio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com