Method for preparing nano-sulfur / graphene oxide composite electrode material

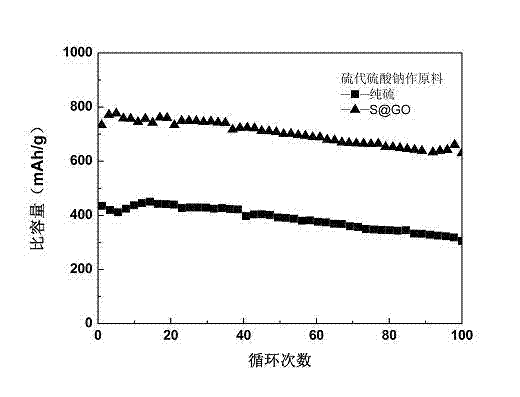

A graphene composite and electrode material technology, applied in battery electrodes, circuits, electrical components, etc., can solve problems affecting battery discharge capacity and cycle performance, reducing the utilization rate of active materials, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] Prepare nano-sulfur / graphene oxide composite material by chemical method, its process and steps are as follows:

[0031] Using sodium thiosulfate as raw material to prepare nano-sulfur / graphene oxide composites: 1.5g Na 2 S 2 o 3 Dissolve in 250ml of deionized water, add 10 mL of 1% sodium dodecylbenzenesulfonate, stir in a clean three-neck flask for 1 h; carefully transfer to 70°C oil bath, slowly add 12 mL of concentrated HCl dropwise, Insulate for 10 minutes; add 50 mL of hydroalcoholic solution containing 20 mg graphene oxide and 10 mg acetylene black under vigorous stirring, cool to room temperature after 20 minutes, centrifuge, and vacuum dry at 60°C for 12 hours to obtain the positive electrode material.

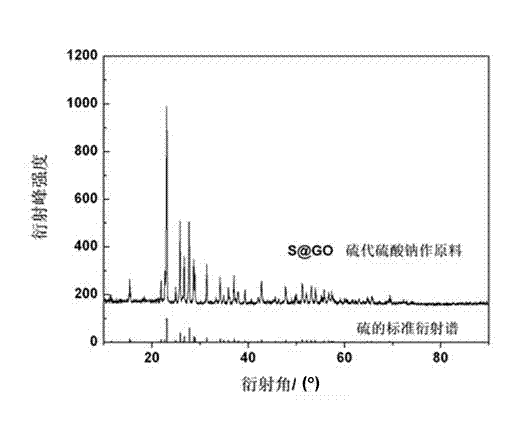

[0032] See attached figure 1 , figure 1 XRD patterns of sublimated sulfur and S graphene oxide (GO). According to the PCPDS card search, it can be seen that the sulfur crystallization generated by the reaction of sodium thiosulfate as a raw material is goo...

Embodiment 2

[0035] Prepare nano-sulfur / graphene oxide composite material by chemical method, its process and steps are as follows:

[0036] Using sodium sulfide and sublimated sulfur as raw materials to prepare nano-sulfur / graphene oxide composites: 0.3g sublimated sulfur and 0.3g Na 2 S was added to deionized water, ultrasonicated for 5 hours until the sublimated sulfur was completely dissolved, and 100 mg of dodecyltrimethylammonium bromide was dispersed into a three-necked flask with 250 mL of deionized water, and stirred evenly until completely dissolved. Mix and stir the above two solutions for 2 hours until it turns orange; carefully transfer to a 70°C oil bath, slowly add 12mL of concentrated HCl dropwise, and keep warm for 10min; add 20mg of graphene oxide and 10mg of acetylene black in 50mL of hydroalcoholic solution under vigorous stirring , cooled to room temperature after 20 min, centrifuged, and vacuum-dried at 60°C to obtain the positive electrode material.

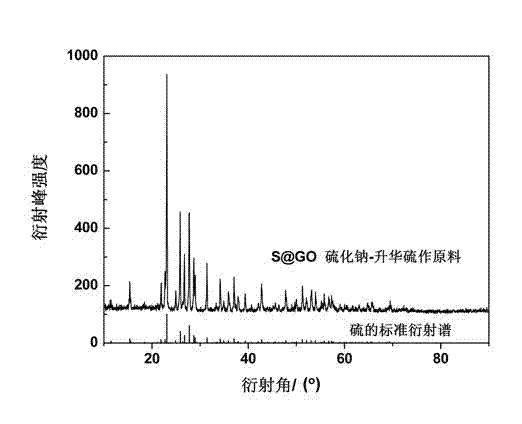

[0037] See att...

Embodiment 3

[0040] Prepare nano-sulfur / graphene oxide composite material by chemical method, its process and steps are as follows:

[0041] Using sodium sulfide and ferric chloride as raw materials to prepare nano-sulfur / graphene oxide composite materials, specifically as follows: 1g sodium sulfide and 0.01g triton were dissolved in 100ml of deionized water respectively, in a clean three-necked flask Mix and stir the two for 1 hour. At 25°C, add 2 mL of concentrated HCl to it. After sodium sulfide and concentrated HCl react to generate hydrogen sulfide, slowly add 100 mL of 1 mol / L ferric chloride solution with a constant pressure dropping funnel, and seal it. In a three-neck flask, stir vigorously for 10 hours, so that ferric chloride can fully oxidize hydrogen sulfide to generate elemental sulfur; add 20 mg of graphene oxide and 10 mg of acetylene black in 50 mL of hydroalcoholic solution under vigorous stirring, cool to room temperature after 20 min, and centrifuge. After vacuum drying...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com