Polarity gel electrolyte and application thereof to solid-state lithium sulfur battery

A gel electrolyte, polarity technology, applied in non-aqueous electrolyte batteries, lithium batteries, secondary batteries, etc., can solve the problem of the shuttle effect of lithium-sulfur batteries that cannot be effectively solved, and achieve performance improvement and risk reduction. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

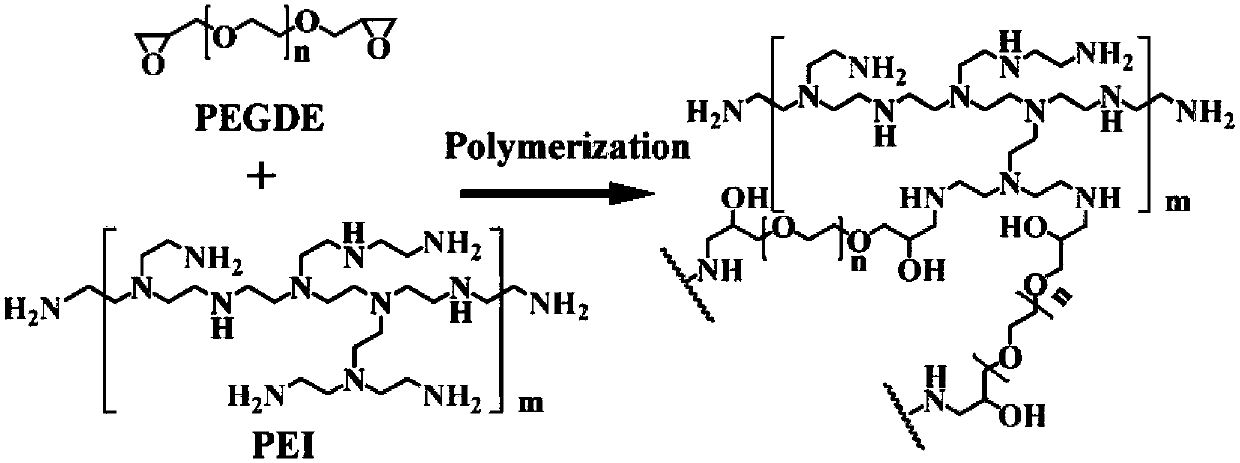

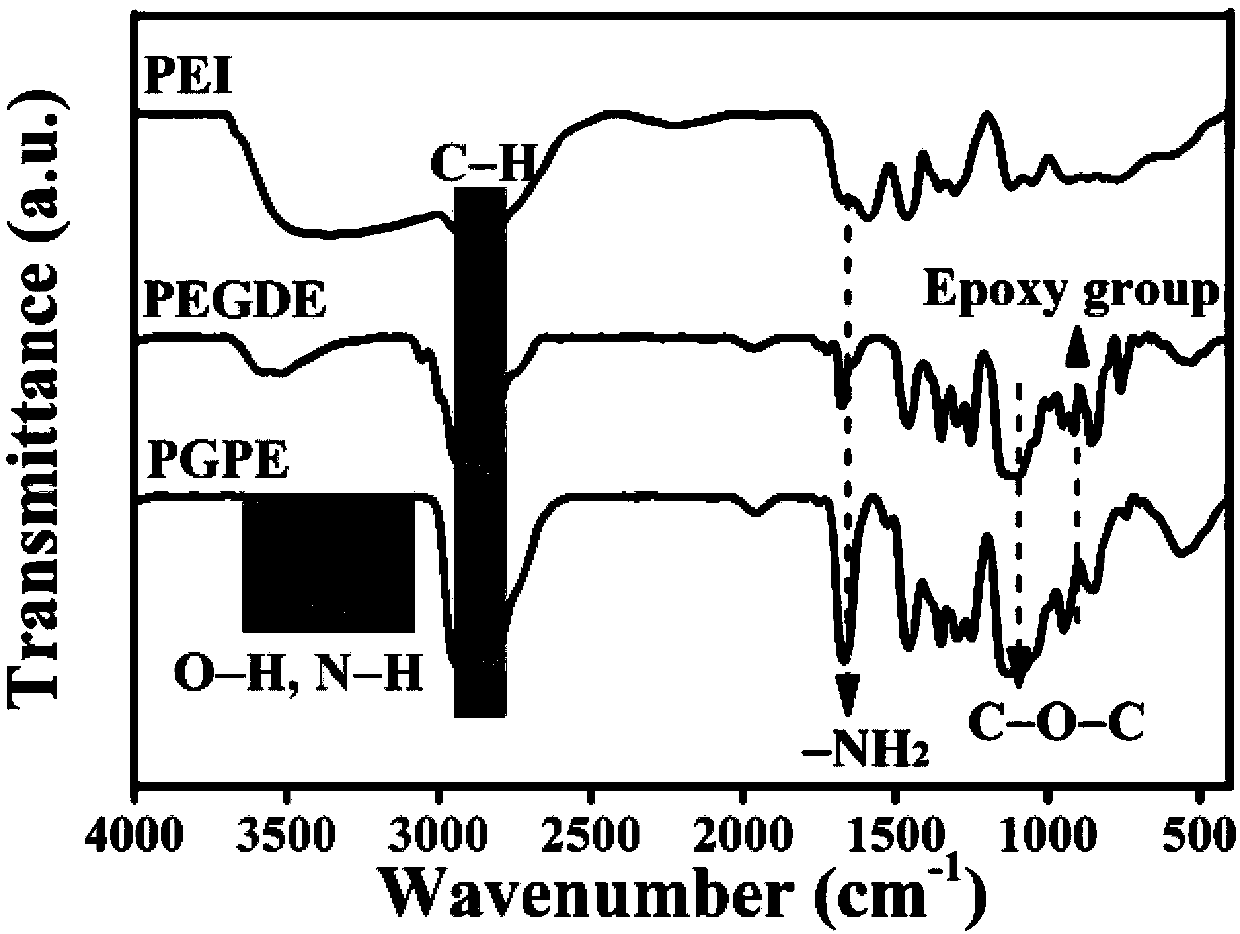

[0025] This embodiment provides a polar gel electrolyte, which includes a polymer matrix and a liquid electrolyte formed in the polymer matrix. The chemical reaction formula of the polymer matrix is as follows figure 1 As shown, the liquid electrolyte is dissolved in 1.0M LiTFSI (bistrifluoromethanesulfonylimide lithium) and 1.0wt% LiNO 3 solution of triethylene glycol dimethyl ether. The preparation of the polymer matrix is as follows: 800 mg polyethylene glycol diglycidyl ether (PEGDE) and 200 mg ethylenediamine-terminated polyethyleneimine (PEI, Sigma-Aldrich; so that the molar ratio of epoxy groups to amino groups is 1 : 1) Add 10ml of N,N-dimethylformamide (DMF) into a container, pass argon into the container for half an hour as a protective gas, then heat to 140°C and keep for 6h for polymerization to obtain a product containing ( That is, the mixed solution of the polymer matrix) (the reaction mechanism is as follows figure 1 Shown; In the present embodiment, beca...

Embodiment 2

[0030]This example provides an application of the polar gel electrolyte in Example 1 in a solid-state lithium-sulfur battery. Disperse in NMP (N-methylpyrrolidone) with a mass ratio of 8:1:1 to make a slurry evenly, coat it on an aluminum foil, and then heat it at 60°C for 24 hours until it is dried to obtain a sulfur carbon electrode; then coat it with The mixed solution of 0.5mg polymer matrix was dried at 60°C so that the polymer matrix was formed on the surface of the sulfur carbon electrode, and its electrochemical performance was as follows: Image 6 shown.

Embodiment 3

[0032] This embodiment provides a polar gel electrolyte, which is basically the same as that in Example 1, except that 900 mg of polypropylene glycol diglycidyl ether and 300 mg of polyether amine are dissolved in N,N-dimethylformamide ( DMF) solvent for polymerization.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com