Sulfur/carbon composite material for lithium-sulfur secondary battery and preparation method thereof

A technology of lithium-sulfur secondary batteries and carbon composite materials, which is applied in battery electrodes, electrode manufacturing, non-aqueous electrolyte battery electrodes, etc., can solve the problems of low electrochemical capacity of sulfur electrodes, achieve good application prospects, improve reactivity, The effect of high charge and discharge efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

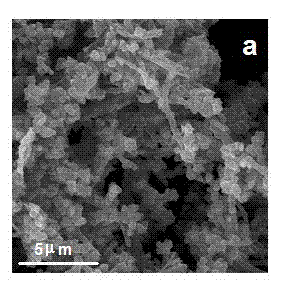

[0024] 1) Preparation of porous carbon: Dissolve 10 g of sucrose in 200 mL of 6M H 2 SO 4 Then, add 0.05g of VGCF nano-carbon fiber after nitric acid treatment, stir vigorously, and after hydrothermal reaction at 180°C for 24h, suction filter, wash and dry; finally, carbonize at 1000°C for 2h at high temperature to obtain a grape bunch structure microporous carbon matrix (such as figure 1 ).

[0025] 2) Preparation of sulfur / carbon composite cathode material: 0.1g of sublimed sulfur and 0.2g of porous carbon were placed in different glass vials, which were then sealed in a reaction vessel filled with Ar, and placed in a muffle furnace at 400 After heating at ℃ for 6h, a sulfur-carbon composite material with a sulfur content of 60% was prepared.

[0026]3) Prepare a circular pole piece with a diameter of 1cm using sulfur-carbon composite material: use acetylene black as the conductive agent, PTFE (polytetrafluoroethylene) as the paste, and combine the prepared sulfur-carbon...

Embodiment 2

[0032] After the microporous carbon matrix was prepared according to the above method, 0.1 g of sublimed sulfur and 0.4 g of porous carbon were placed in different glass sample vials, which were then sealed in a reaction kettle filled with Ar, and heated in a muffle furnace at 400 After heating at ℃ for 6h, a sulfur-carbon composite material with a sulfur content of 70% was prepared. After being prepared into a positive electrode sheet, the battery was assembled in the same way using the same organic carbonate electrolyte.

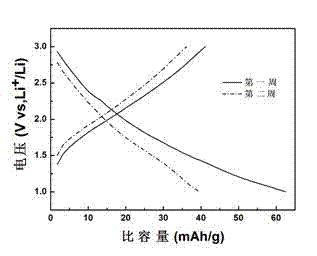

[0033] Charge and discharge tests were carried out on the installed battery at room temperature, with a voltage range of 1.0V-3.0V and a current density of 100mA / g. like Figure 6 As shown, the capacity of the sulfur / carbon composite cathode remained at about 450 mAh / g after 50 cycles, and its charge-discharge Coulombic efficiency remained at 100%, indicating that the composite material with higher sulfur content also has good electrochemical performance....

Embodiment 3

[0036] According to the method described in Example 1, after preparing a sulfur / carbon composite material and a positive electrode sheet with a sulfur content of 60%, the (PP13)TFSI ionic liquid containing 1M LiTFSI is used as the electrolyte (wherein, PP13 represents N-methyl-N-propane Basepiperidinium cation, TFSI means N (CF 3 SO 2 ) 2- anion), the battery was assembled in the same manner.

[0037] Charge and discharge tests were carried out on the installed battery at room temperature, with a voltage range of 1.0V-3.0V and a current density of 100mA / g. like Figure 7 As shown, the charging capacity of the sulfur / carbon composite was 1200 mAh / g in the first week, and after 100 cycles, the capacity remained above 800 mAh / g, and the Coulombic efficiency remained at 100% after 3 weeks.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com