Lithium-sulfur battery positive electrode material and preparation method thereof

A positive electrode material, lithium-sulfur battery technology, applied in lithium batteries, battery electrodes, positive electrodes, etc., to achieve the effects of inhibiting the shuttle effect, enriching the pore structure, and good cycle stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

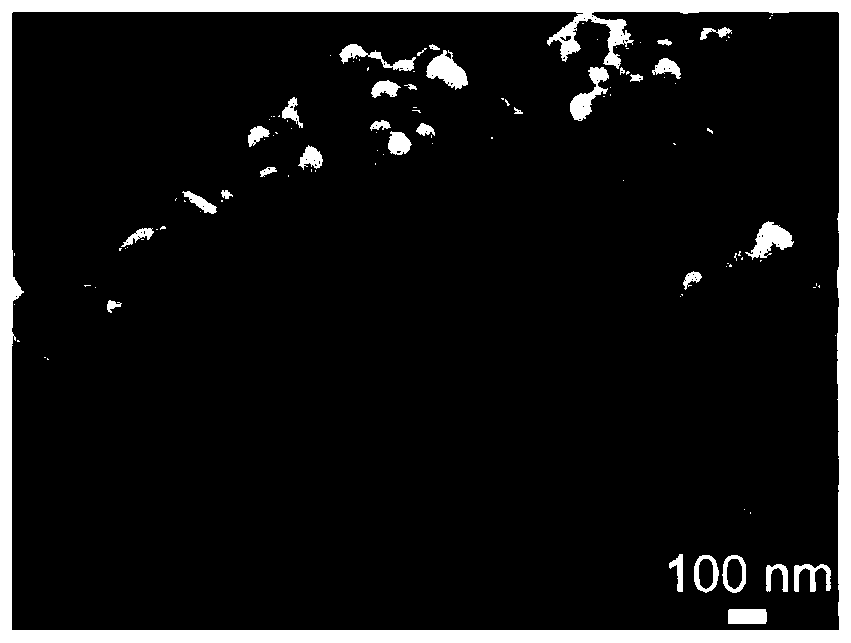

[0060] Dissolve zinc nitrate hexahydrate and 2-methylimidazole respectively in 100mL of methanol at a molar ratio of 1:5, stir at room temperature to obtain a stable solution, then mix the two solutions, stir magnetically for 0.5h, and rotate at a speed of 400r·min -1 , and finally left to stand for 24h to obtain ZIF-8. The sample was washed several times with ethanol, transferred and dried in an oven at 75°C to obtain pure ZIF-8, as figure 1 shown.

Embodiment 2

[0062] Using ZIF-8 obtained in Example 1, according to the mass ratio of trithiocyanuric acid, ZIF-8 and polyacrylonitrile of 0.25:1:1, dissolved in 15mL N-N dimethylformamide (DMF) solution, stirred for 12h, obtained Uniform spinning solution. The spinning liquid is injected into the electrospinning device, and the voltage, temperature, distance from the needle to the receiving plate and the liquid feeding speed are set, and electrospinning is performed to obtain a polyacrylonitrile / ZIF-8 film. Dry in a vacuum oven at 75 °C for 2 h to remove residual DMF solvent. The polyacrylonitrile / ZIF-8 film was placed in a tube furnace, kept at 240 °C for 2 h in an air atmosphere, and then heated in N 2 Incubate at 800°C for 6 hours under air. Soak the sample in 3mol L -1 The elemental zinc remaining in the sample was removed by HCl solution to obtain SN-PCNF-1 with the morphology as figure 2 shown.

Embodiment 3

[0064] Using the ZIF-8 obtained in Example 1, according to the mass ratio of trithiocyanuric acid, ZIF-8 and polyacrylonitrile at 0.25:1:2, dissolve it in 15mL N-N dimethylformamide (DMF) solution, stir for 12h to obtain a uniform spinning solution. Then inject the spinning liquid into the electrospinning device, set the voltage, temperature, the distance from the needle to the receiving plate and the liquid feeding speed, and perform electrospinning to obtain the polyacrylonitrile / ZIF-8 film. Dry in a vacuum oven at 75 °C for 2 h to remove residual DMF solvent. The polyacrylonitrile / ZIF-8 film was placed in a tube furnace, kept at 240 °C for 2 h in an air atmosphere, and then heated in N 2 Incubate at 800°C for 6 hours under air. Soak the sample in 3mol L -1 HCl solution removes the residual elemental zinc in the sample to obtain SN-PCNF-2 with the morphology as image 3 shown.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com