Preparation and application of NiO/C composite electrode material taking foamed nickel sheet as substrate

A nickel foam sheet and composite material technology, which is applied in the manufacture of hybrid capacitor electrodes, hybrid/electric double layer capacitors, etc., can solve problems such as peeling and poor cycle performance, and achieve simple and easy operation, reduce electrode impedance, and ease volume The effect of swelling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0028] The first aspect of the present invention provides a method for preparing a NiO / C composite material based on a nickel foam sheet, which includes: calcining the nickel foam sheet, coating PDA, and carbonizing it.

[0029] Since the present invention generates NiO in situ on the foamed nickel sheet, the surface of NiO is coated with active materials. For NiO, under the support of the foamed nickel sheet and the coating of the active material, the upper and lower forces are balanced, and NiO and the active material They are all distributed in a plane, and the two phases are more tightly combined, which solves the problems of uneven stress and poor bonding effect of the active material coated on the surface of a single particle. Excellent cycle performance, lower impedance.

[0030] In one or more embodiments of the present invention, the calcination temperature is 550-900°C, and the calcination time is 0.5-3h, preferably 650°C, 2h. In this process, without adding any rea...

Embodiment 1

[0050] Use untreated nickel foam sheet; set the heating rate in the muffle furnace to 5°C / min, keep it at 650°C for 2h, and let it cool down to room temperature naturally. Weigh 0.01 g of dopamine hydrochloride, dissolve it in 20 ml of tris solution with pH=8.5, put it into the above-mentioned treated foam nickel sheet, soak for 48 hours, take it out and dry it in a vacuum oven. Put the product dried in the previous step into a tube furnace in a nitrogen atmosphere to raise the temperature at a rate of 2°C / min, keep it at 700°C for 2 hours, and then cool down to room temperature naturally to obtain the final sample.

[0051] The final sample processed in the previous step was used as the working electrode, the calomel electrode was used as the reference electrode, the platinum sheet electrode was used as the counter electrode, and a 3mol / L KOH solution was used as the electrolyte to assemble a three-electrode system for electrochemical testing.

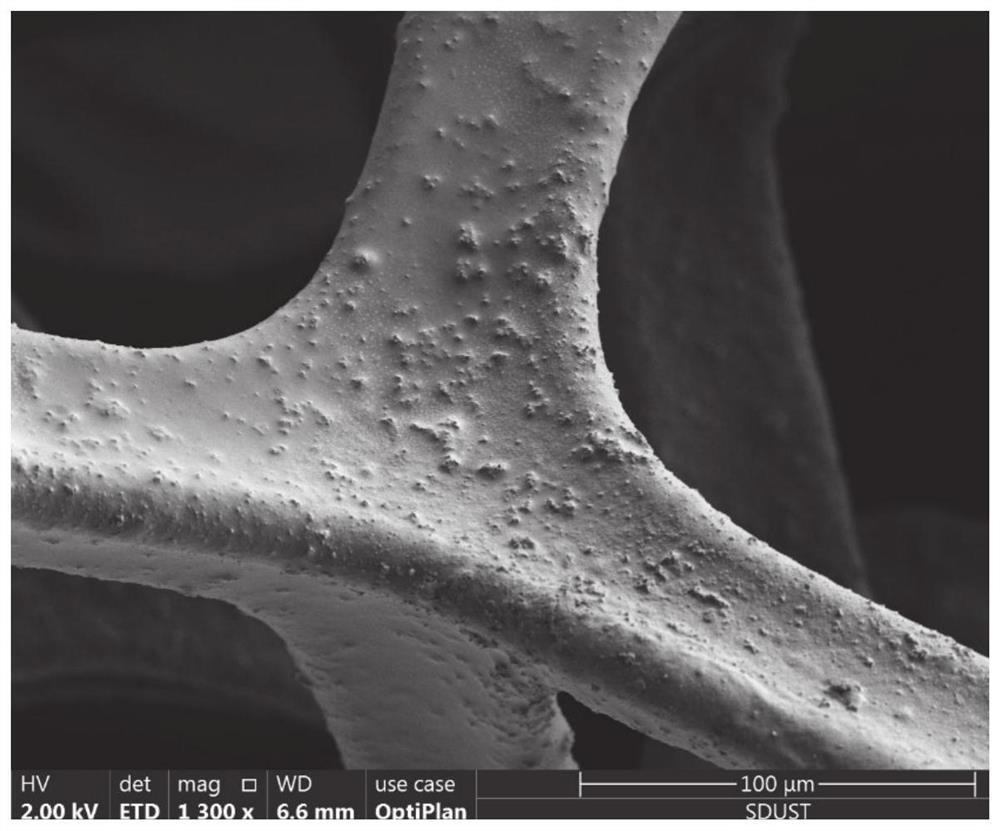

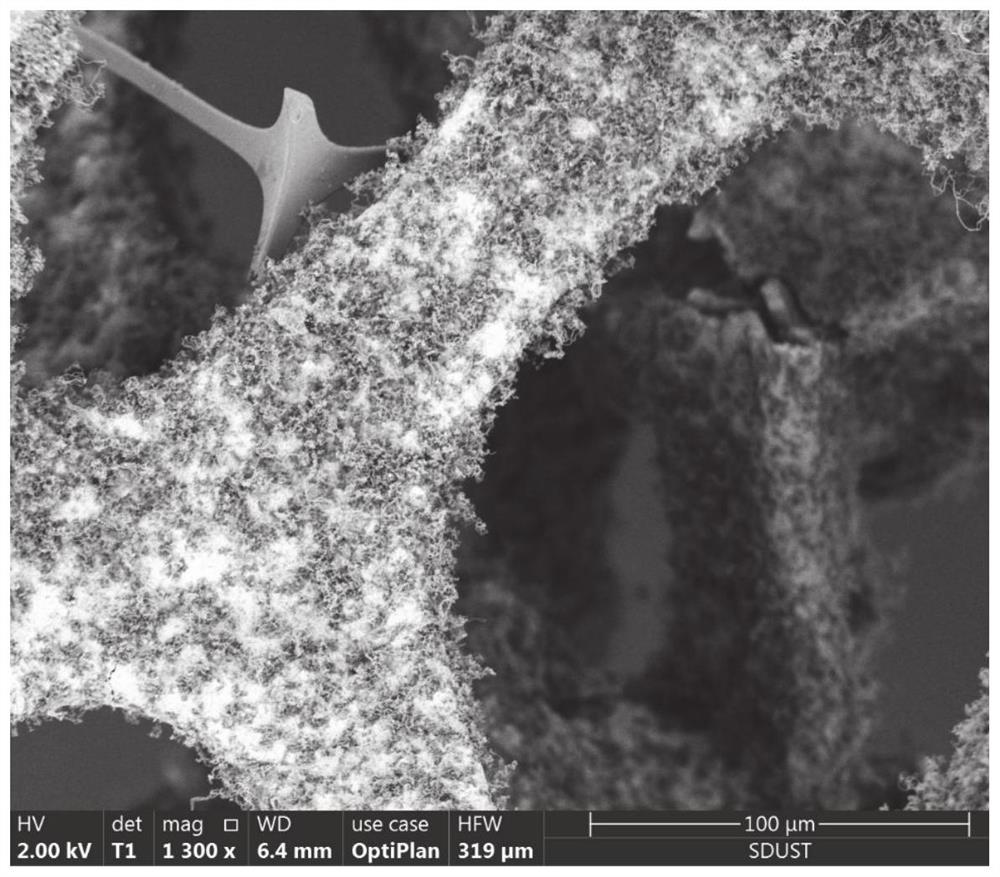

[0052] figure 1 It is a scann...

Embodiment 2

[0059] Same as Example 1, the only difference is that the muffle furnace calcination temperature is 550°C.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com