Nickel oxide/graphite composite nanomaterial used for lithium ion battery, and preparation method and application thereof

A technology of composite nanomaterials and lithium-ion batteries, applied in battery electrodes, secondary batteries, electrochemical generators, etc., can solve the problems of easy aggregation of nanomaterials, achieve volume expansion relief, simple preparation process, and increased reaction contact area big effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

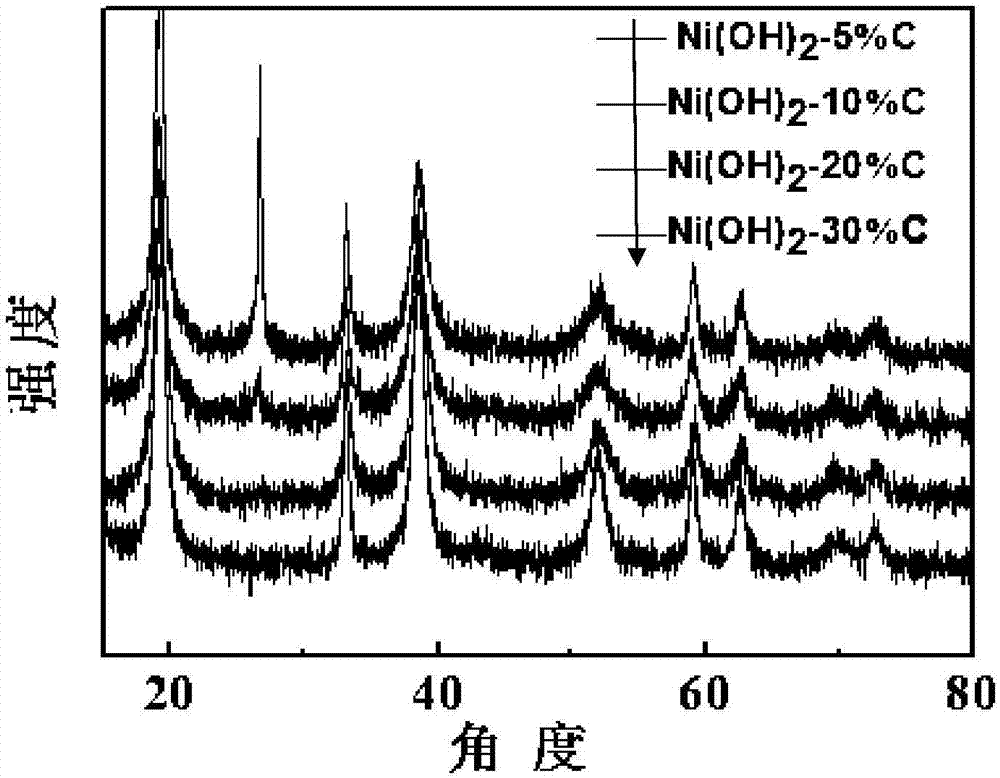

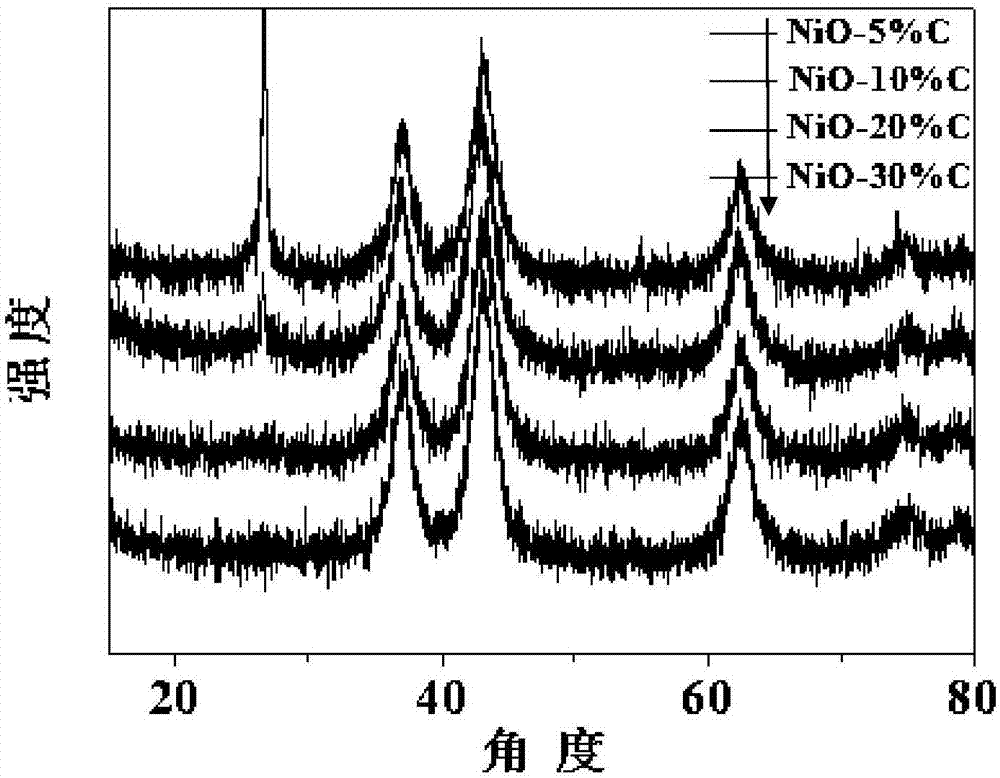

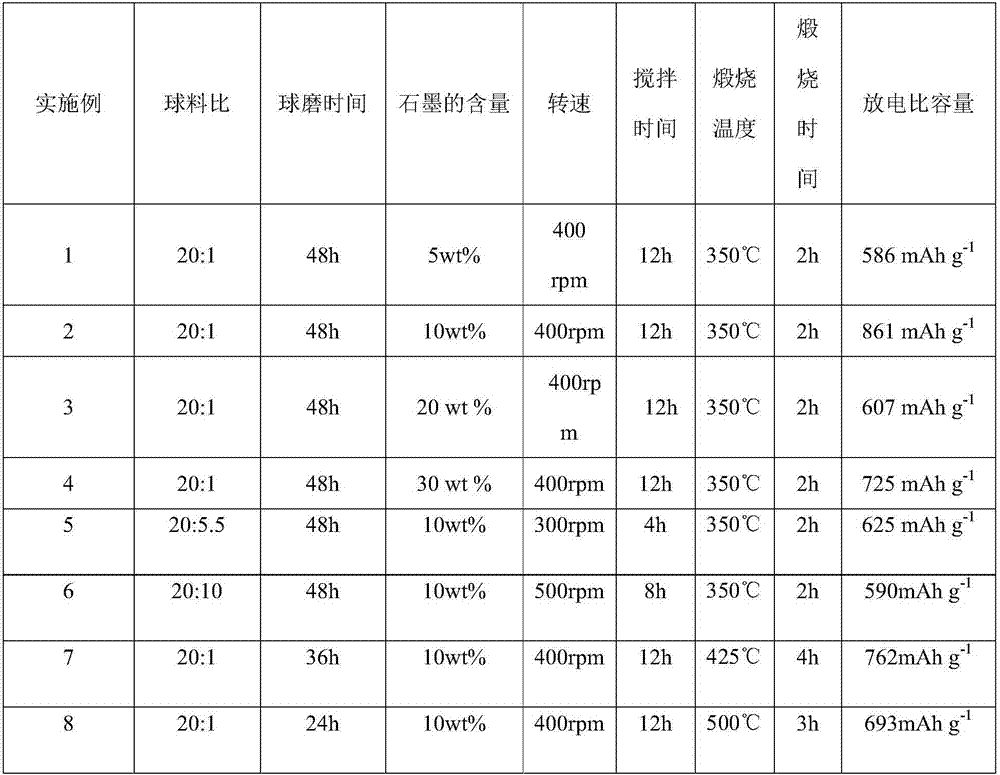

Embodiment 1

[0037] Weigh 30g of natural flake graphite successively, put 15g of anhydrous sodium nitrate into a 100ml beaker, add 60ml of concentrated nitric acid dropwise under magnetic stirring, wash with distilled water after stirring for 12 hours until the pH is neutral, and dry to obtain acidified graphite. Weigh successively 0.3596g of acidified graphite, 8.9904g of nickel hydroxide, and 187g of zirconium balls (grinding medium), add in the ball mill jar, add sealing ring, ball mill at 400rpm for 48h, filter out the zirconium balls through a sieve to obtain the sample obtained Nickel hydroxide / graphite composite nanomaterials. The obtained material was placed in a tube furnace, and in a nitrogen atmosphere, the temperature was raised to 350° C. at a rate of 5° C. per minute, and kept for 2 hours to obtain a nickel oxide / graphite composite nanomaterial.

[0038] Weigh 0.2g of nickel oxide / graphite composite nanomaterials, 0.025g of carbon black, and 0.025g of PVDF, grind them thoroug...

Embodiment 2

[0040]Weigh 30g of natural flake graphite successively, put 15g of anhydrous sodium nitrate into a 100ml beaker, add 60ml of concentrated nitric acid dropwise under magnetic stirring, wash with distilled water after stirring for 12 hours until the pH is neutral, and dry to obtain acidified graphite. Weigh successively 0.7670g acidified graphite, 8.5826g nickel hydroxide, 187g zirconium balls (grinding medium), add in the ball mill pot, add sealing ring, ball mill 48h under 400rpm, the sample that obtains is filtered out zirconium balls through sieve, obtains Nickel hydroxide / graphite composite nanomaterials. The obtained material was placed in a tube furnace, and in a nitrogen atmosphere, the temperature was raised to 350° C. at a rate of 5° C. per minute, and kept for 2 hours to obtain a nickel oxide / graphite composite nanomaterial.

[0041] Weigh 0.2g of nickel oxide / graphite composite nanomaterials, 0.025g of carbon black, and 0.025g of PVDF, grind them thoroughly in a mort...

Embodiment 3

[0043] Weigh 30g of natural flake graphite successively, put 15g of anhydrous sodium nitrate into a 100ml beaker, add 60ml of concentrated nitric acid dropwise under magnetic stirring, wash with distilled water after stirring for 12 hours until the pH is neutral, and dry to obtain acidified graphite. Take by weighing 1.5677g acidified graphite, 7.7819g nickel hydroxide, 187g zirconium balls (grinding medium), add in the ball mill pot, add sealing ring, ball mill 48h under 400rpm, the obtained sample is filtered out the zirconium balls through a sieve to obtain Nickel hydroxide / graphite composite nanomaterials. The obtained material was placed in a tube furnace, and in a nitrogen atmosphere, the temperature was raised to 350° C. at a rate of 5° C. per minute, and kept for 2 hours to obtain a nickel oxide / graphite composite nanomaterial.

[0044] Weigh 0.2g of nickel oxide / graphite composite nanomaterials, 0.025g of carbon black, and 0.025g of PVDF, grind them thoroughly in a mo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com