Patents

Literature

70results about How to "With large-scale industrial production" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Dynamically-repairable polyurethane based on oxime and preparation method thereof

ActiveCN108314763AHigh yieldImprove responseOrganic compound preparationOximes preparationHydroxylamineRoom temperature

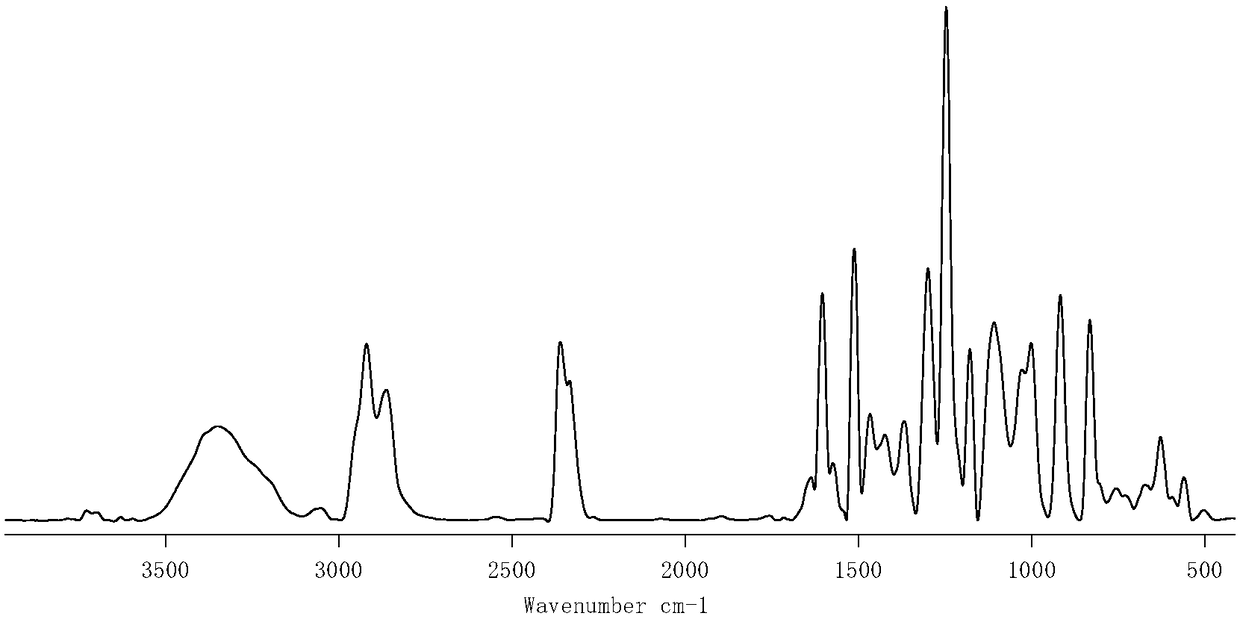

The invention provides a polyfunctional group oxime and a preparation method thereof, and novel dynamically-repairable polyurethane based on the oxime and a preparation method thereof, the oxime is ahighly reactive organic substance, the oxime and an isocyanate can be prepared into the polyurethane at room temperature without a catalyst. It is noteworthy that the oxime is usually obtained by reacting a carbonyl compound (an aldehyde or a ketone) with hydroxylamine under mild conditions, and the process is an atomically-economic, high-yield and simple reaction. The thermosetting oxime-based polyurethane is cut into small pieces, and the small pieces can be hot-pressed again for molding under the conditions of 90-120 DEG C and 1-100 MPa, and the obtained thermosetting polyurethane substantially restores original mechanical properties; the reaction for preparing the polyurethane can be carried out without the catalyst at the room temperature. The preparation method is simple, the preparation process has wide sources of raw materials and low production cost, and the method has a prospect of large-scale industrial production.

Owner:INST OF CHEM CHINESE ACAD OF SCI

Preparation method of polyimide/graphene composite material and product of material

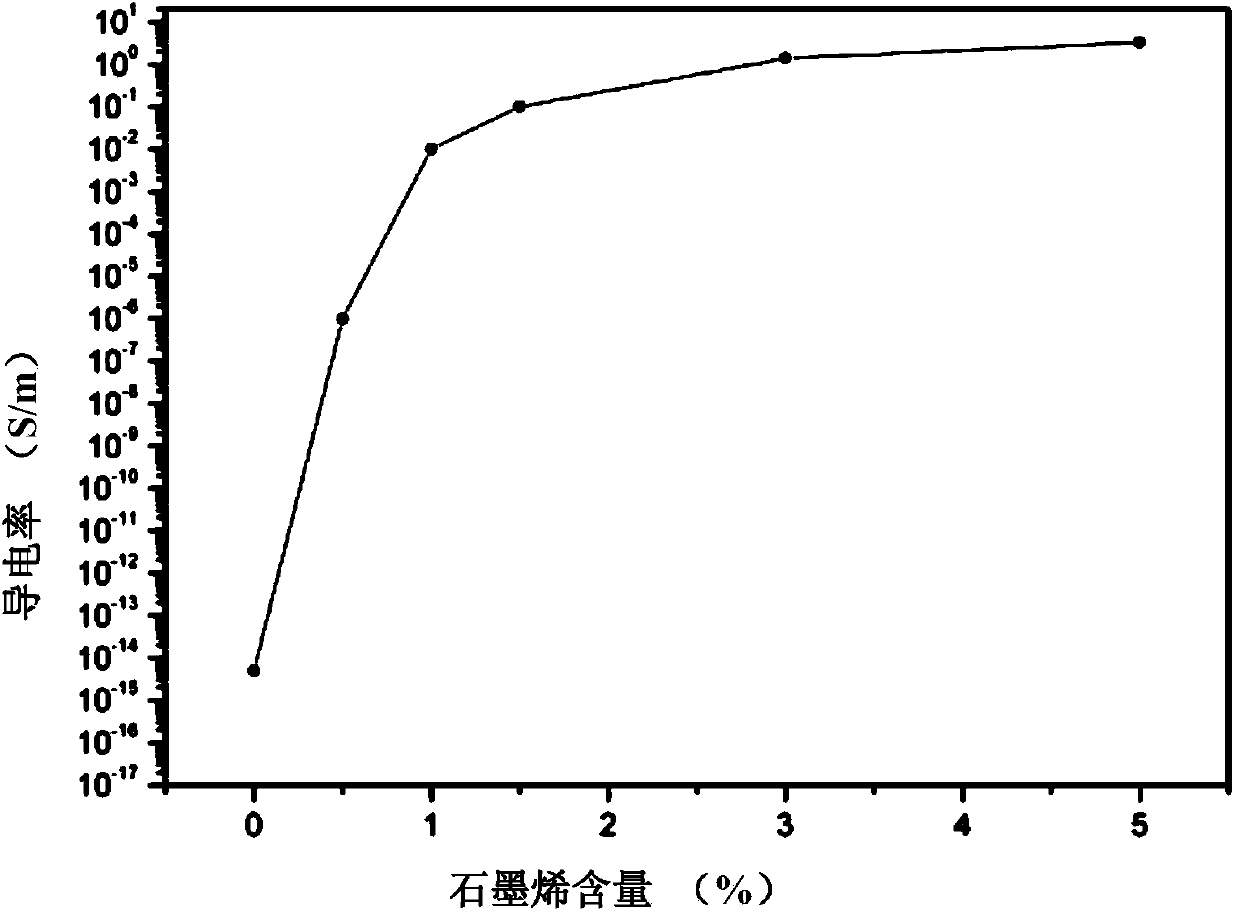

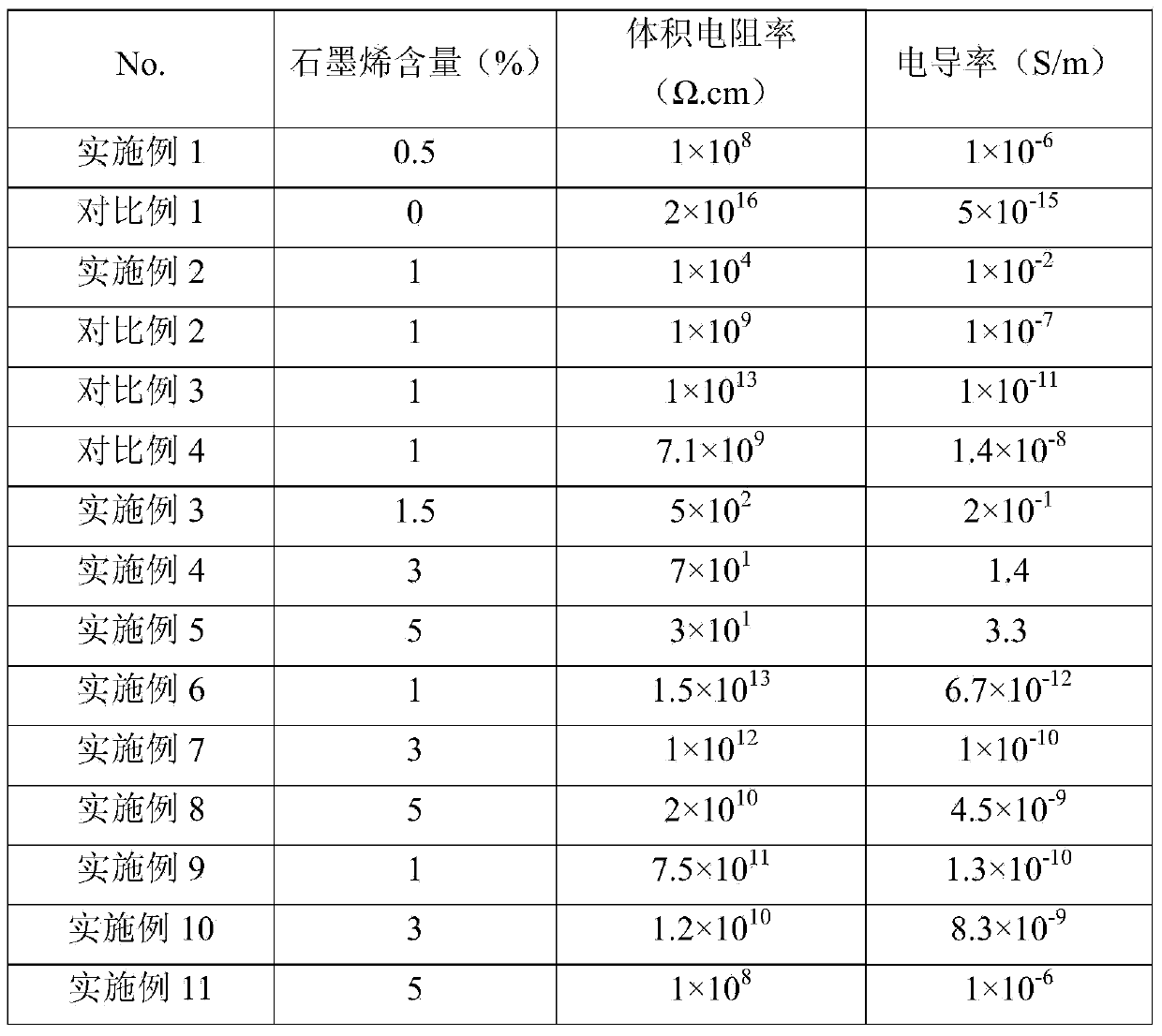

ActiveCN104194335ADoes not involve the use ofWith large-scale industrial productionGraphiteCvd graphene

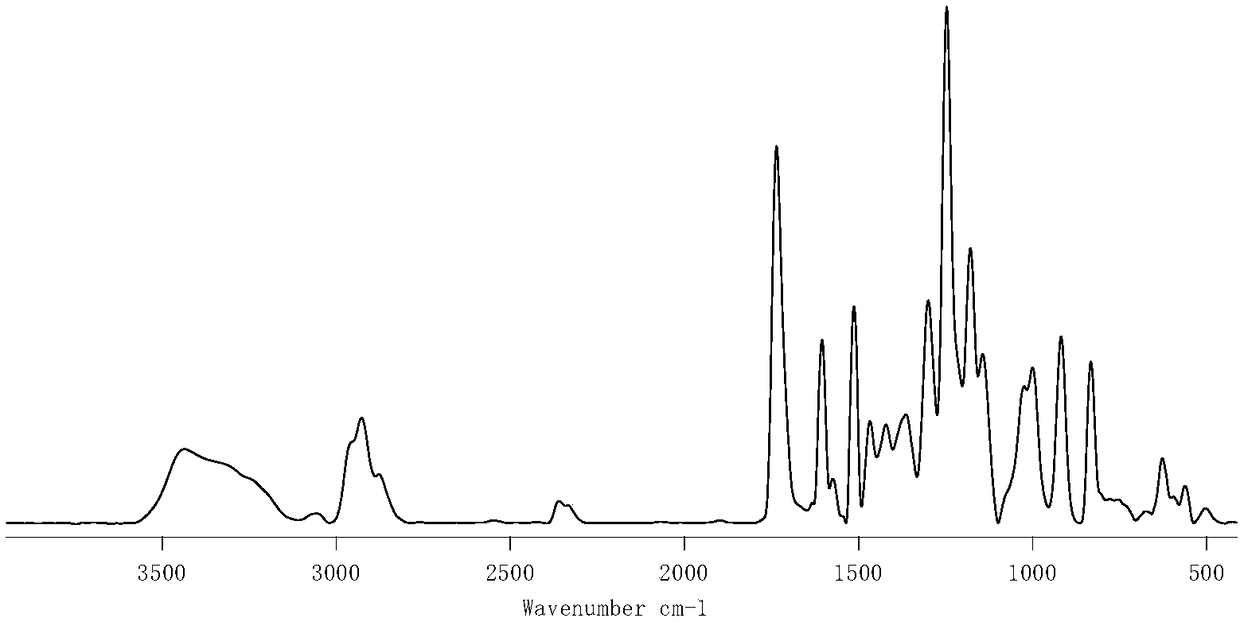

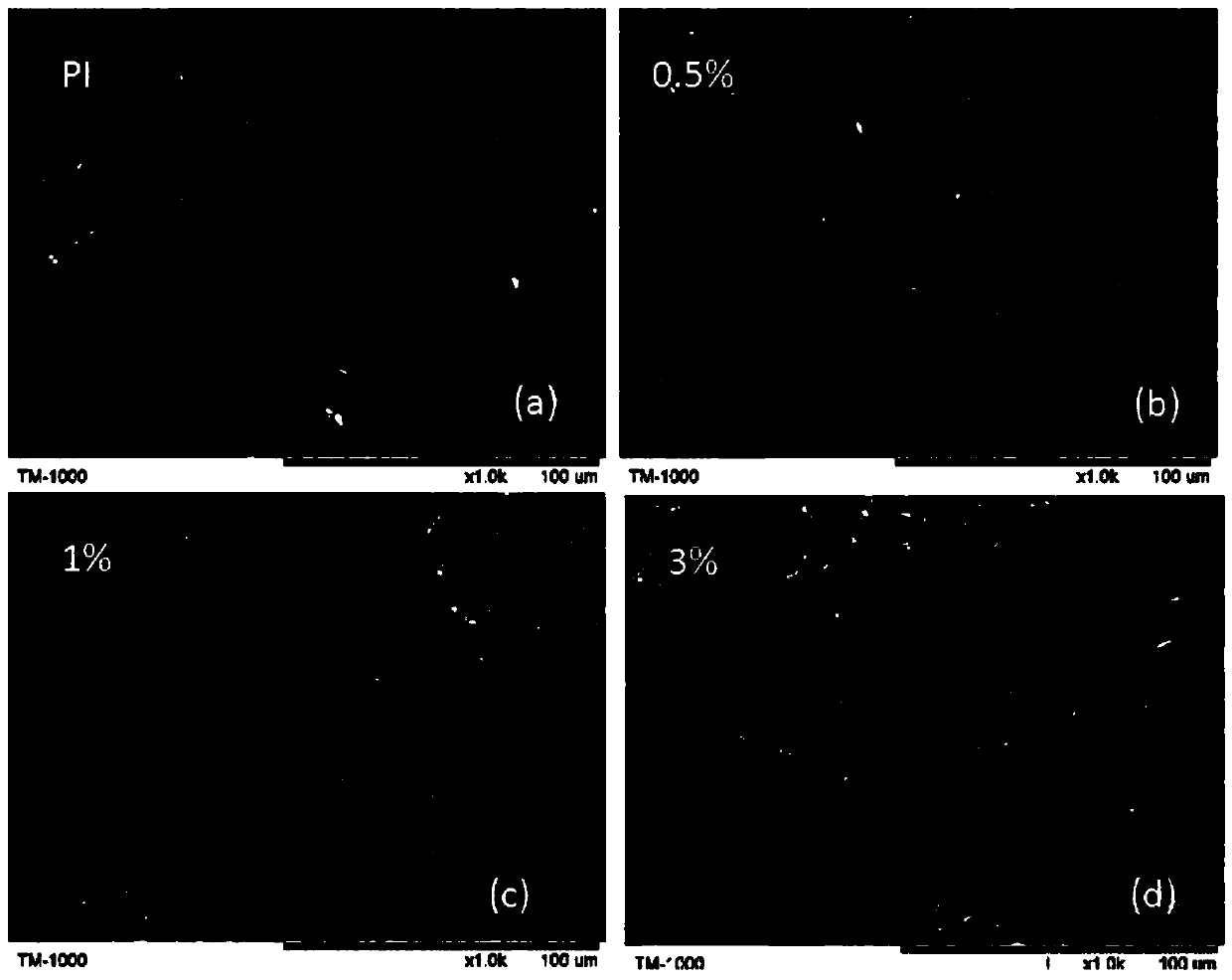

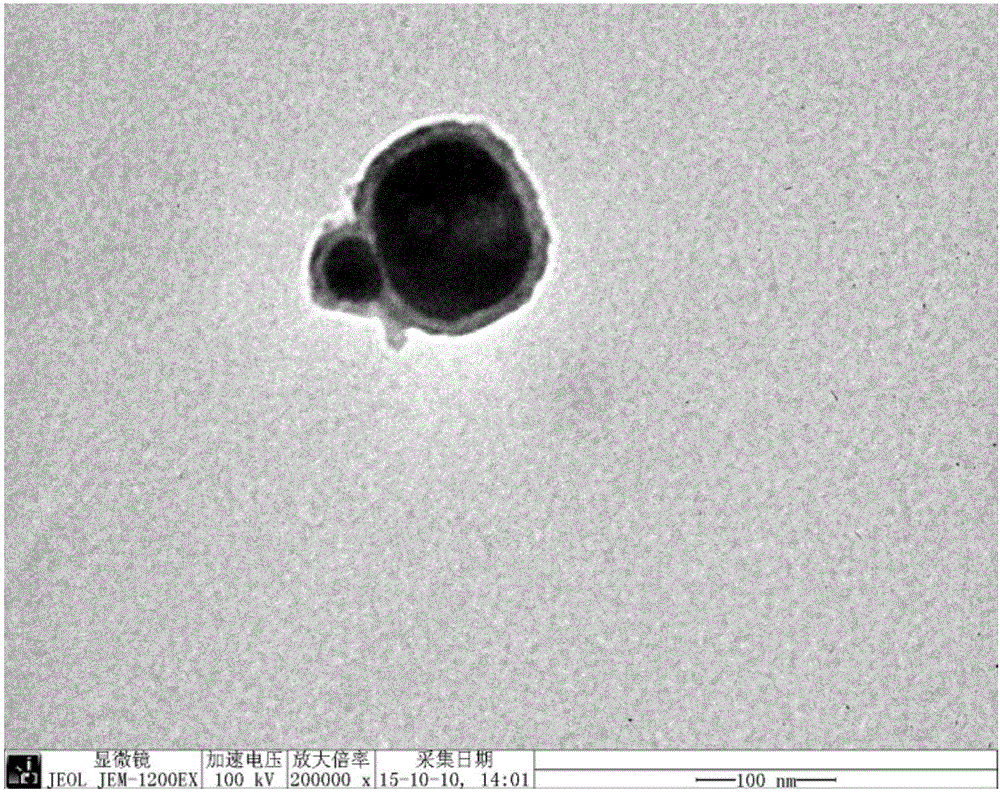

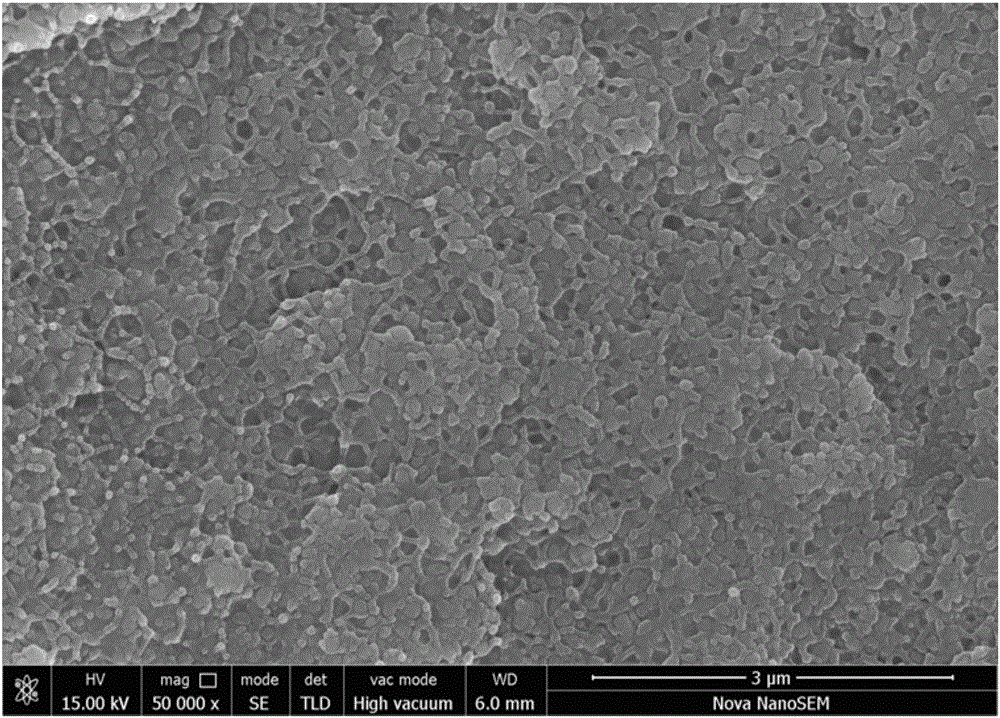

The invention discloses a preparation method of a polyimide / graphene composite material. The preparation method comprises the following steps: firstly, mixing polyimide with graphite and stirring at a high speed to obtain polyimide / graphene composite particles; and then carrying out hot press molding on polyimide / graphene composite particles to prepare the composite material. According to the preparation method of the polyimide / graphene composite material disclosed by the invention, under the condition that any reagent is not added, the modification of grapheme on polyimide is achieved so as to obtain the composite material with excellent electrical conductivity and the preparation method is simple and environmentally friendly and is suitable for industrial production.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

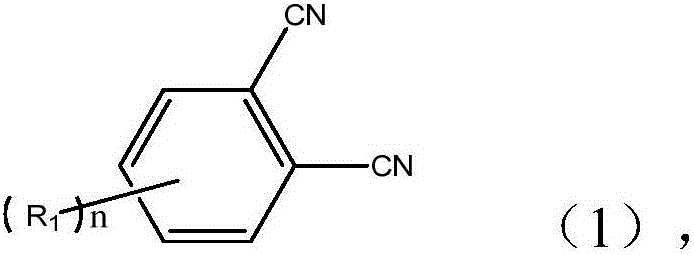

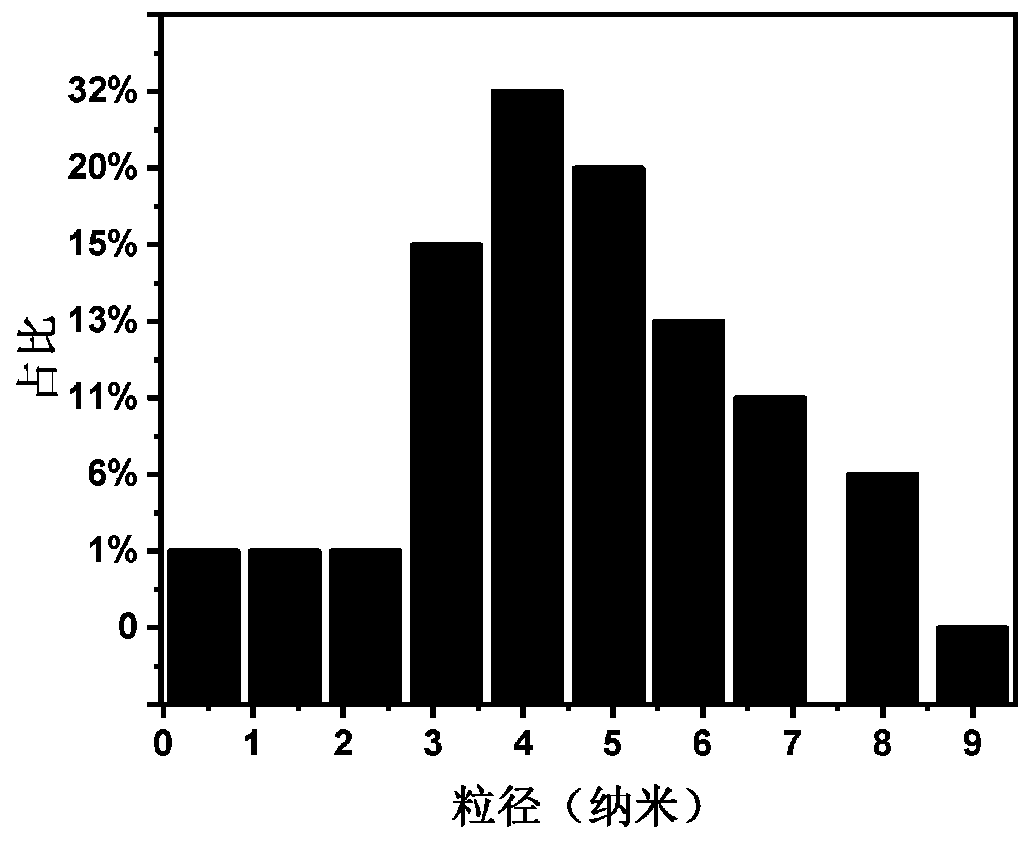

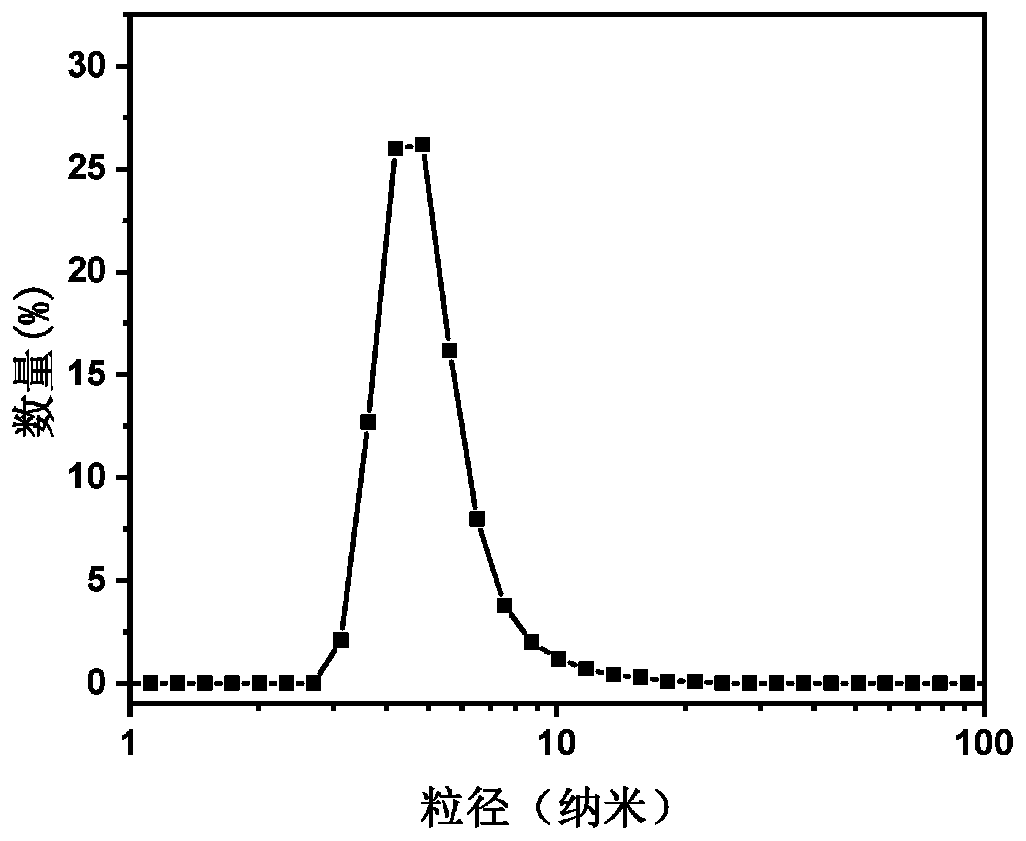

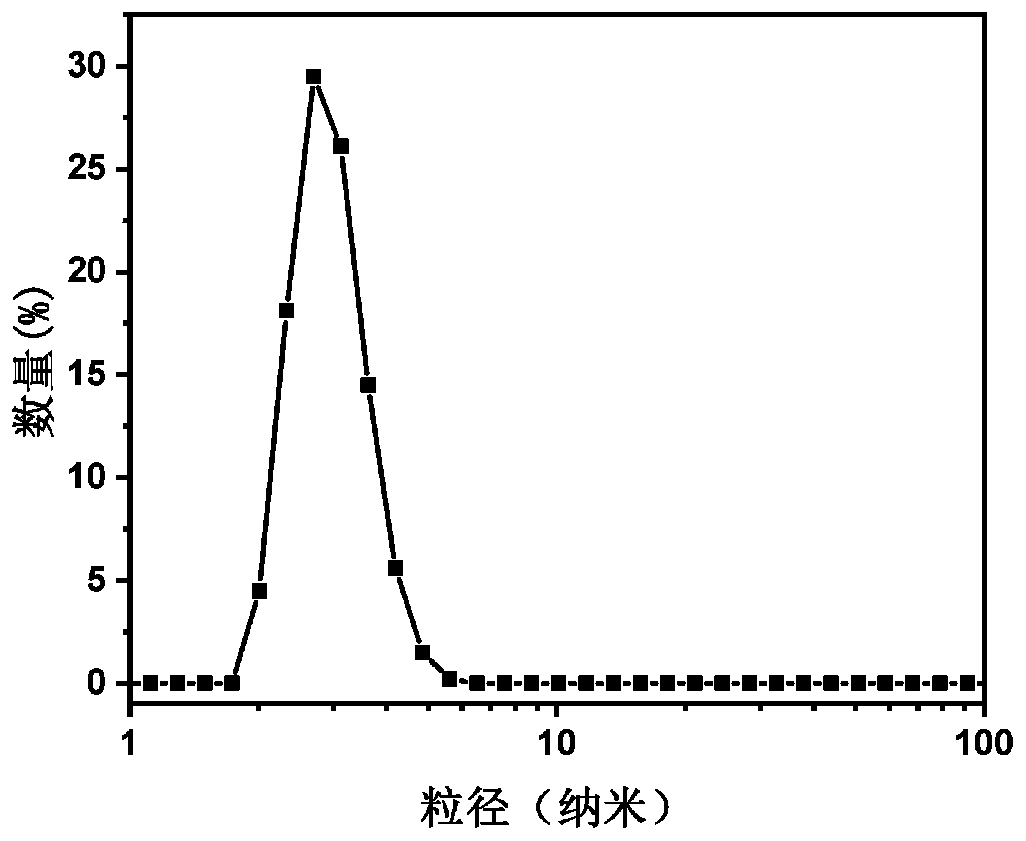

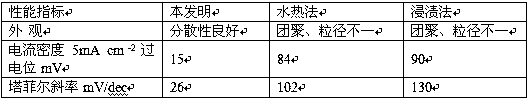

Polymer-based hyperbranched metal phthalocyanine@nano-barium titanate composite material as well as preparation method and application thereof

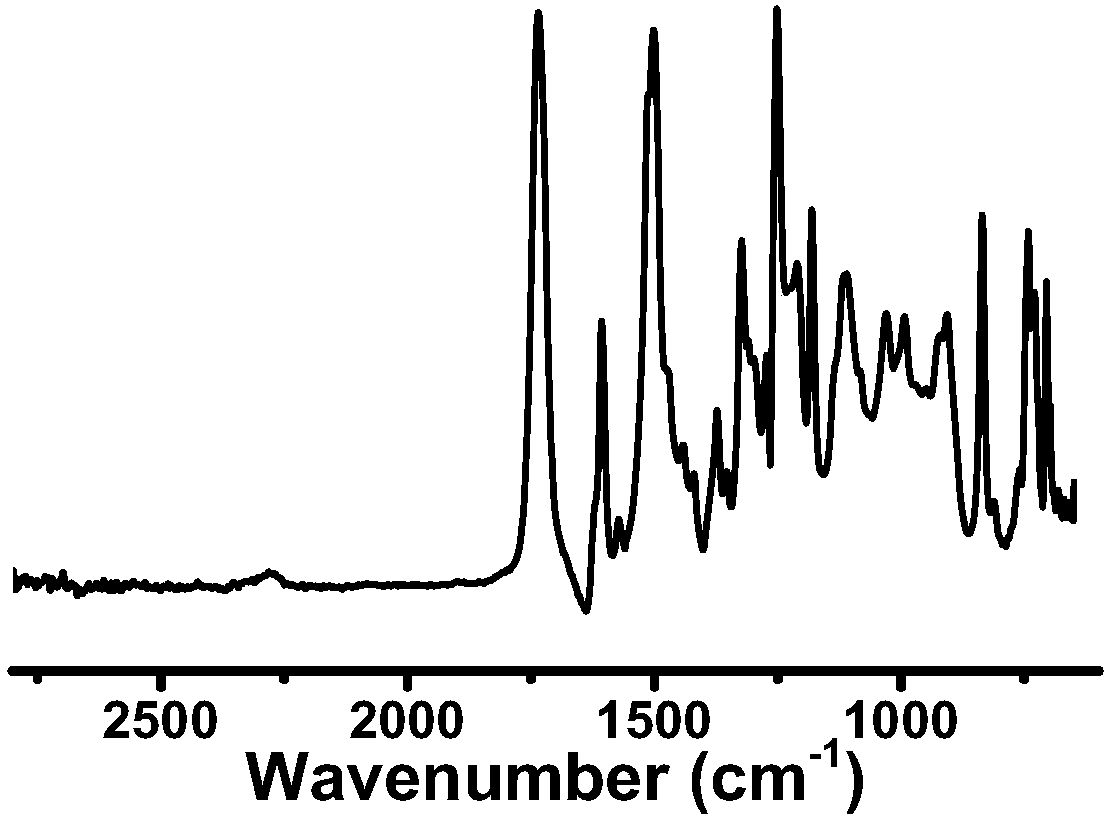

The invention discloses a polymer-based hyperbranched metal phthalocyanine@nano-barium titanate composite material as well as a preparation method and application thereof. A hyperbranched metal phthalocyanine@nano-barium titanate particle in the composite material has a core-shell structure; an inner core nano-barium titanate is subjected to surface treatment, and double-cyano terminated functional groups are introduced; then hyperbranched metal phthalocyanin is grafted to further cover the inner core nano-barium titanate; organic functionalization modification is carried out on the surface of the nano-barium titanate, so that surface energy difference of inorganic nanoparticles and an organic polymer is reduced, and an interface effect is enhanced; gathering of particles is reduced, and the dispersity of the nanoparticles in a polymer base body is improved, so that the polymer-based hyperbranched metal phthalocyanine@nano-barium titanate composite material with a high dielectric constant, low dielectric loss and high breakdown strength is obtained; the composite material also has excellent processing performance. The composite material disclosed by the invention is applicable to preparation of electronic and electrical equipment including embedded capacitors, thin film capacitors, high-energy-storage capacitors and the like.

Owner:JILIN UNIV

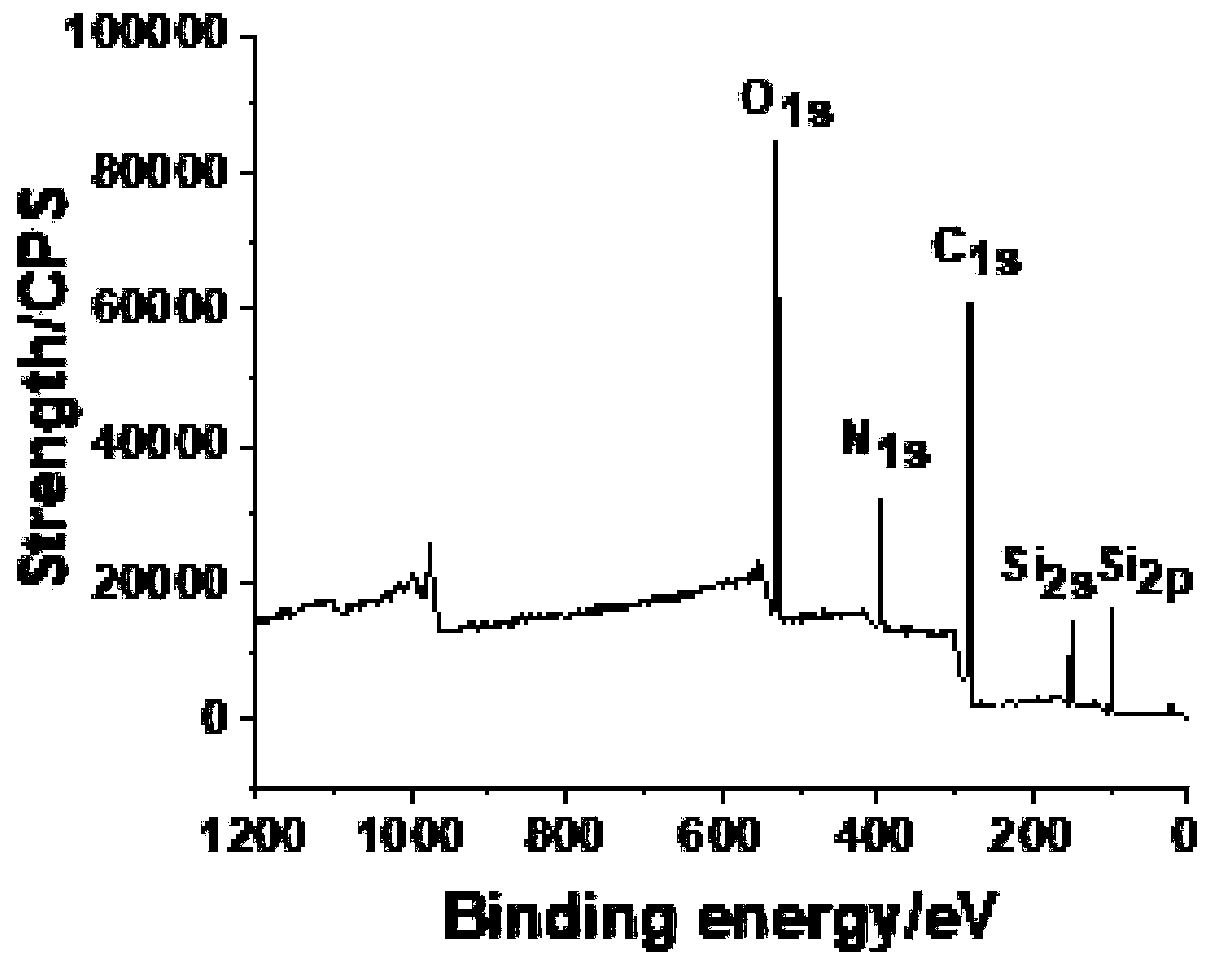

High-refractive-index wear-resistant hardened coating composition and preparation method of hardened film thereof

InactiveCN110713746AHigh stability solid contentHigh solid contentCoatingsRefractive indexOrganic inorganic

The invention discloses a high-refractive-index wear-resistant hardened coating composition and a preparation method of a hardened film thereof. The preparation method comprises the following steps: firstly, preparing nano zirconium oxide by utilizing a hydrothermal method and the like, and then connecting a hydrophobic group to the surface of zirconium oxide by virtue of a double modification method of olefine acid, olefine acid ester and a silane coupling agent so as to disperse the zirconium oxide into an organic solvent, and the organic-phase nano zirconium oxide particle dispersion with good dispersity is obtained. Zirconium oxide nanoparticles and light-cured resin are compounded to obtain the composite material with excellent performance of organic and inorganic materials, and the composite material is stable in property, high in hardness, high in wear resistance, good in water resistance and corrosion resistance and high in refractive index, and can be applied to the fields ofprotection of electronic products and electronic components or coating of furniture and artware and the like.

Owner:BEIJING UNIV OF CHEM TECH

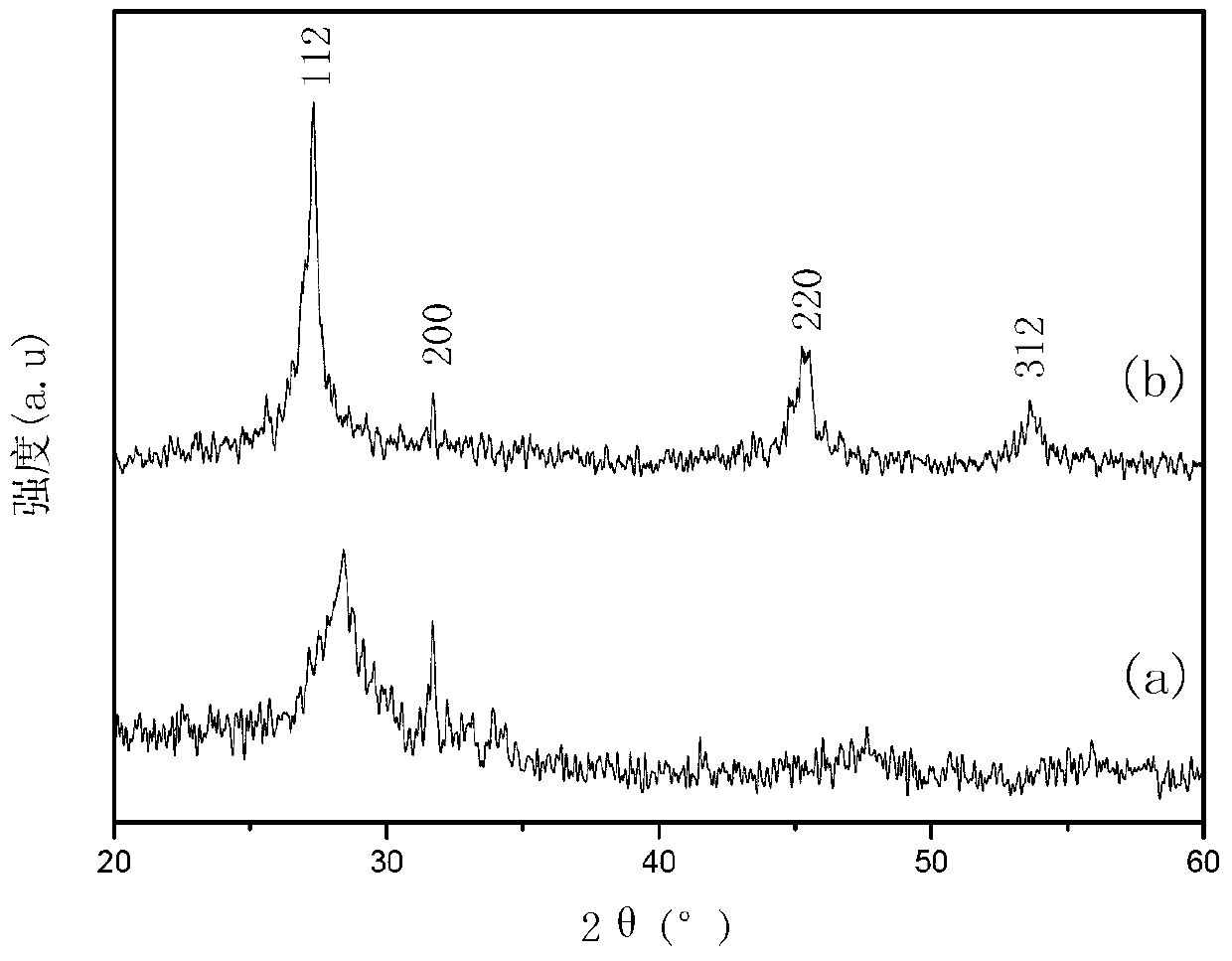

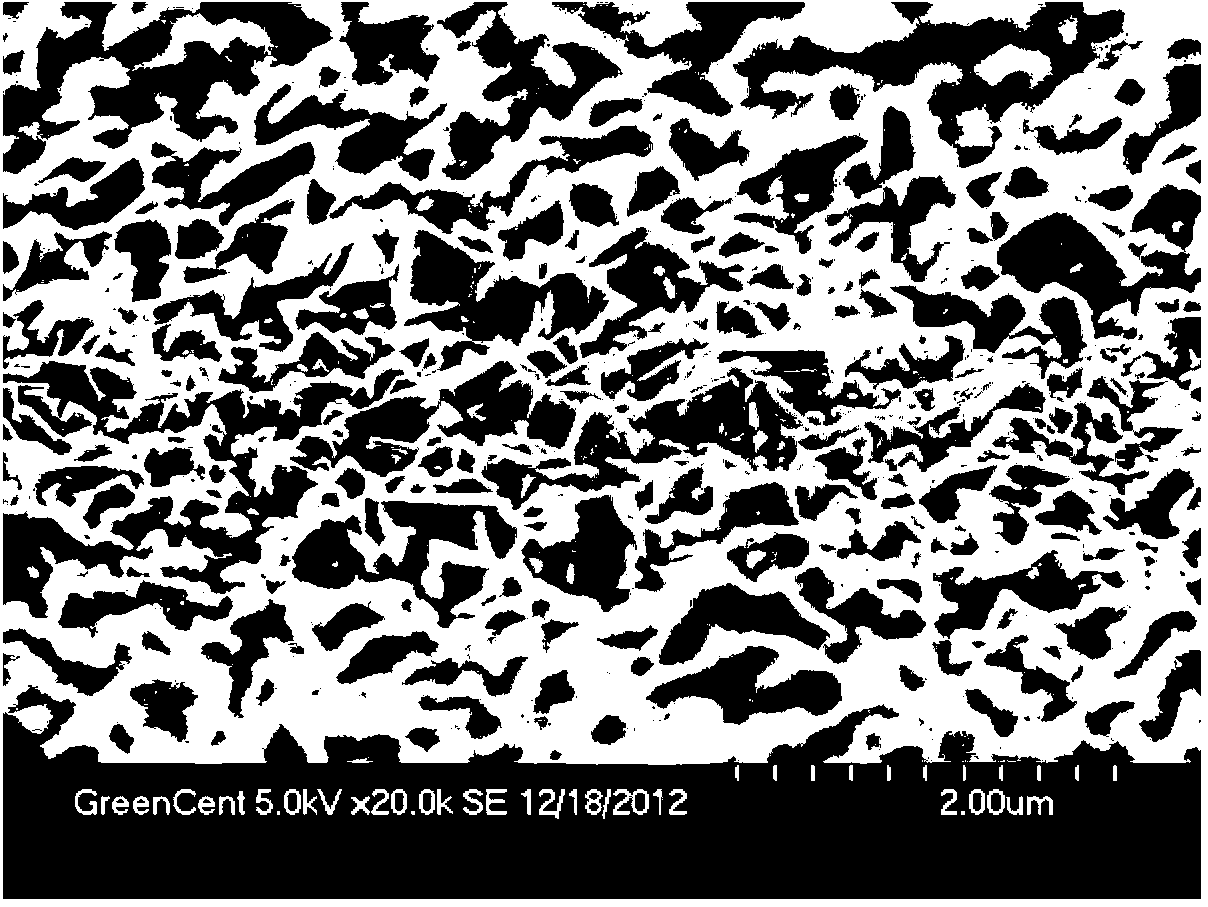

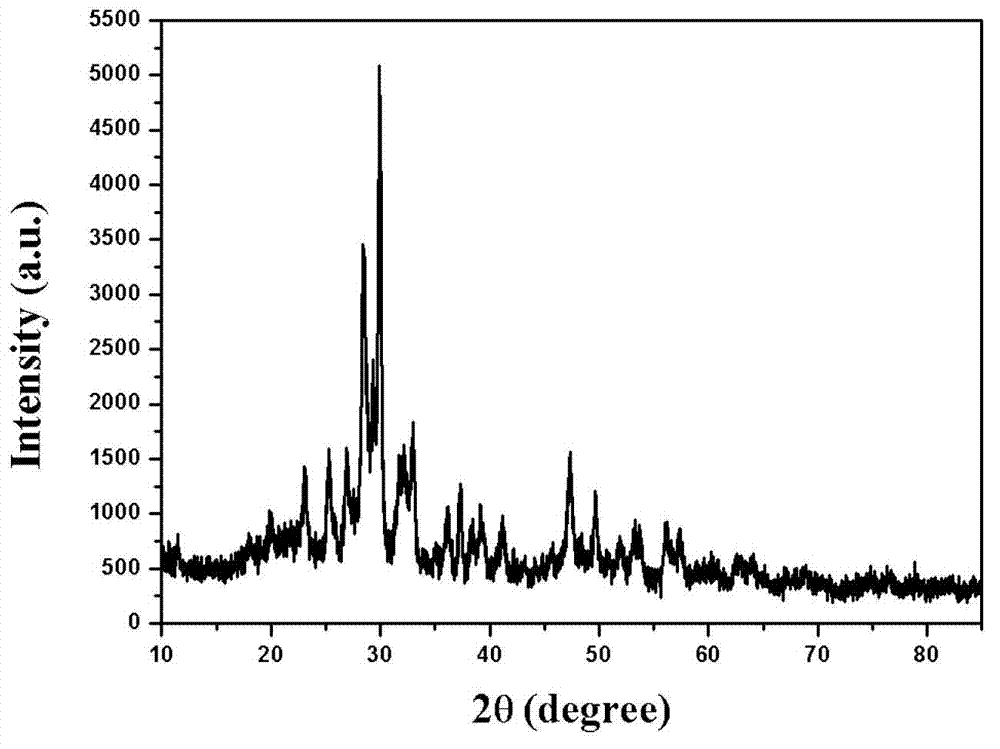

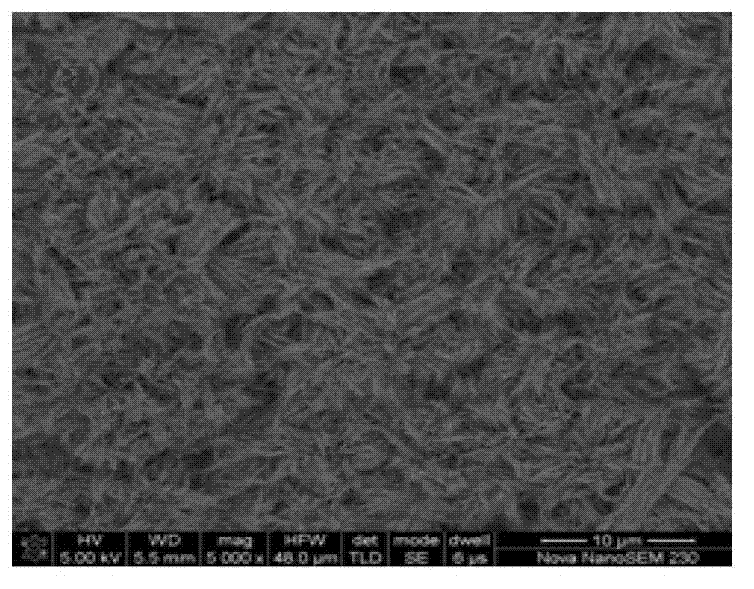

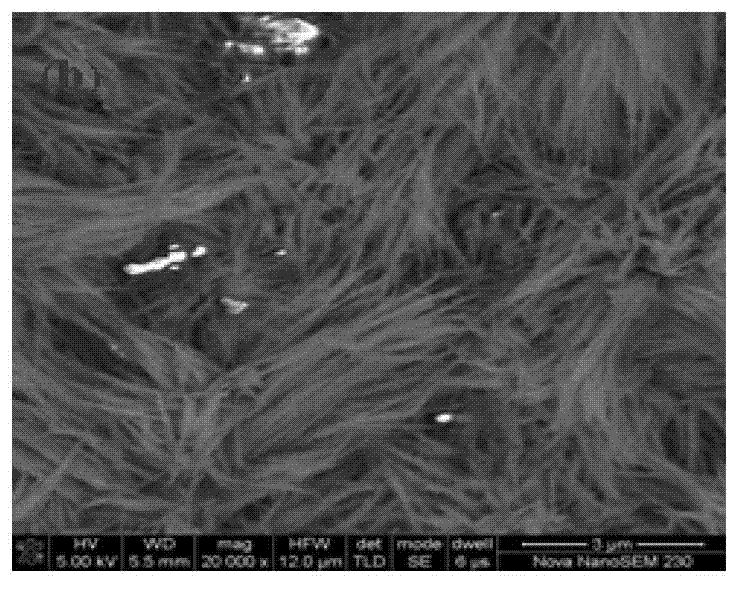

Method for preparing copper-zinc-tin-sulfide solar cell absorbing layer with homogeneous solution method

InactiveCN103346215AIncrease profitReduce carbon residueFinal product manufactureSemiconductor devicesTechnology developmentSulfur

The invention discloses a method for preparing a copper-zinc-tin-sulfide solar cell absorbing layer with a homogeneous solution method and belongs to the field of functional materials. The method comprises the following steps that (a) a substrate is washed, (b) front-body solution is prepared, (c) a front-body thin film is prepared, and (d) annealing processing is carried out. According to the method for preparing the copper-zinc-tin-sulfide solar thin film, expensive raw materials and equipment are of no need, each technology step can be well controlled, toxic macromolecule solvent is of no need, a large amount of residual carbon in the copper-zinc-tin-sulfide solar thin film preparing process is avoided, large-grained and compact copper-zinc-tin-sulfide solar cell absorbing layer thin film preparing is facilitated, the technology is simple, cost is low, repeatability is high, a new idea is provided for environment-protection low-cost high-conversion-efficiency copper-zinc-tin-sulfide thin-film solar cell technology development, and the potential of large-scale industrial production is achieved.

Owner:BEIJING UNIV OF TECH

Fresh sweet corn normal-temperature fresh-keeping method

ActiveCN102524384ARetain nutrientsFresh tasteSeed preservation by heatingCounter pressureEngineering

The invention discloses a fresh sweet corn normal-temperature fresh-keeping method, which comprises the following steps that: 1) fresh sweet corns are peeled, corn silk is removed, and the treated corns are washed after the fresh sweet corns are harvested; 2) the sweet corns are placed into an internal package bag, the internal package bag is vacuumized, the vacuum package bag is placed inside an outer package bag, and then the outer package bag is inflated by nitrogen gas and is sealed; 3) the well-packed sweet corns are arranged inside a counter-pressure sterilization pot to be steamed; 4)temperature inside the counter-pressure sterilization pot is decreased while the pressure is maintained constant; 5) the pressure and the temperature inside the pot are slowly reduced; and 6) the sweet corns are taken out of the pot and are stored and kept fresh below the temperature of 25 DEG C. The method has simple, convenient and rapid process, and the color preservation, sterilization and freshness preservation of the corns can be integrated by adopting the indirect heating method. The method is simple and rapid to operate, has low cost, short processing time and low processing cost, canpreserve more nutrients of the sweet corns, and can prevent the decrease of soluble solids of the fresh sweet corns when the fresh sweet corns are frozen in low-temperature to preserve the freshness.

Owner:TIANJIN JIESHENG DONGHUI FRESH PRESERVATION TECH

Natural plant dyestuff dyeing and finishing processing method for loose cellulose fiber

ActiveCN103938468AShort processImprove color yield and color fastnessDyeing processHemp fiberRegenerated cellulose

The invention relates to a natural plant dyestuff dyeing and finishing processing method for a loose cellulose fiber. Loose cotton and hemp fibers are processed by the following steps: oxygen bleaching, hot washing, directly dyeing in a same bath, soaping, fixing and softening, dewatering, baking and packaging into a product, wherein the cotton and hemp fibers after oxygen bleaching are added to a natural additive and natural plant dyestuff to be directly dyed in the same bath and then are directly soaped and fixed; regenerated loose cellulose fibers are processed by the following steps: directly dyeing in the same bath, soaping, fixing and softening, dewatering, baking and packaging into the product, wherein the regenerated loose cellulose fiber from which spinning oil is not removed is added to the natural additive and the natural plant dyestuff to be directly dyed in the same bath, and then are directly soaped and fixed. The natural plant dyestuff dyeing and finishing processing method has the advantages that the method does not need uncoiling and washing procedures for pretreatment, the natural additive and the natural dyestuff are adopted to dye in the same bath, direct dyeing can be carried out by simple washing after oxygen bleaching, and the colorized light and the dyeing rate are not affected.

Owner:苏州麻朵纺织科技有限公司

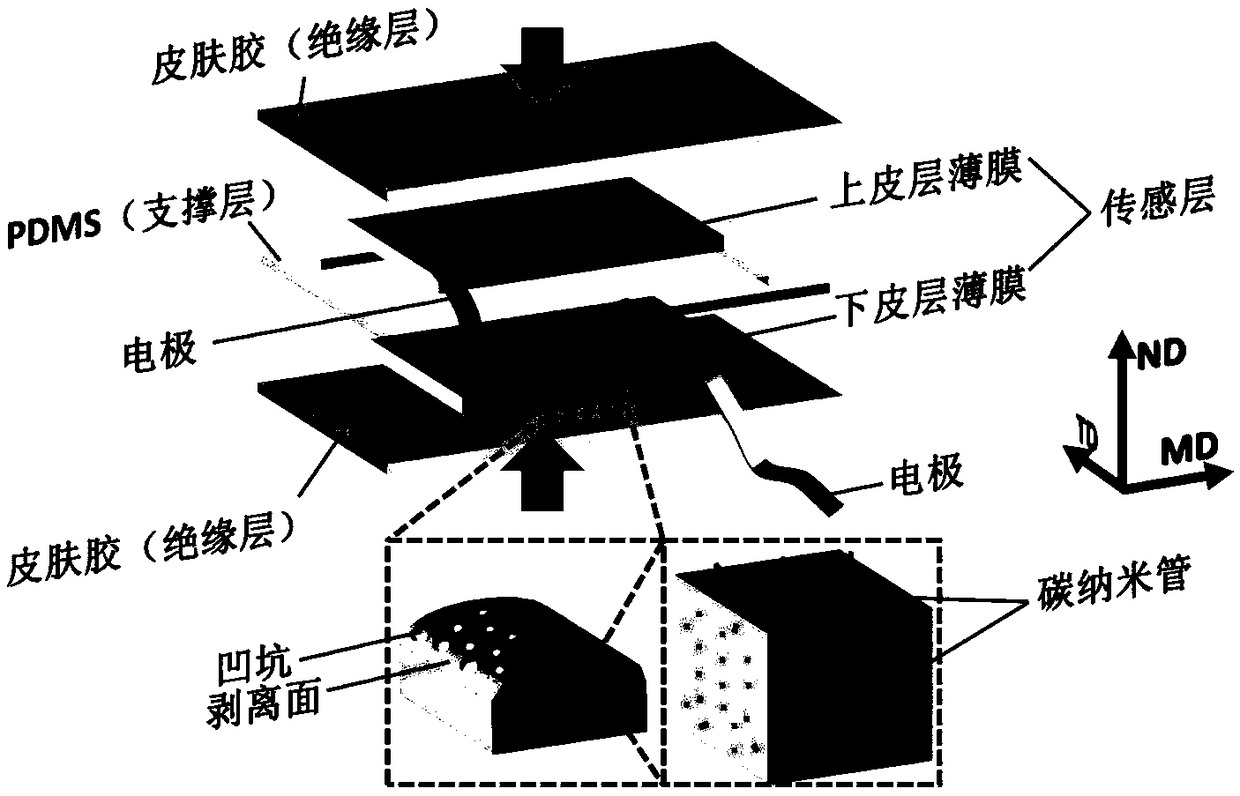

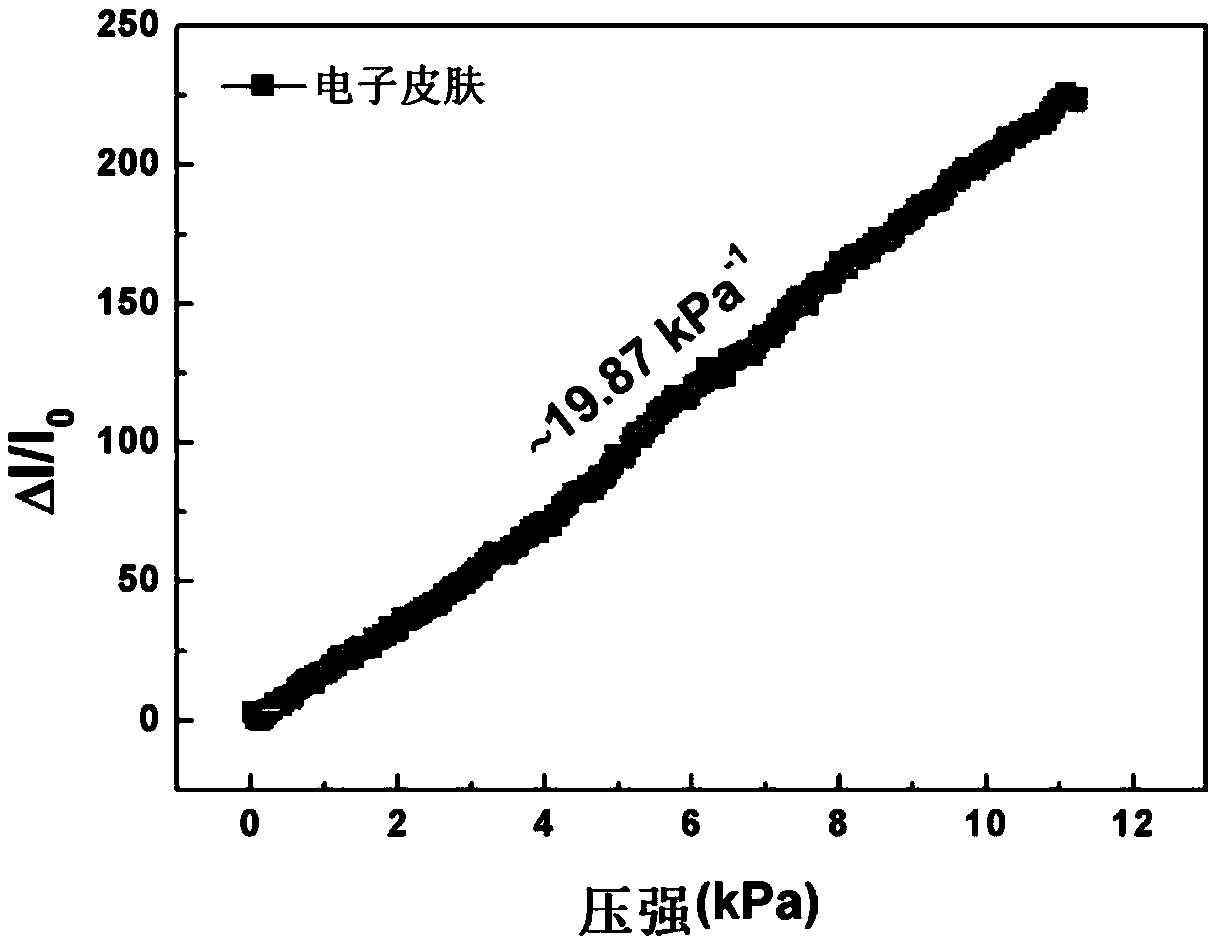

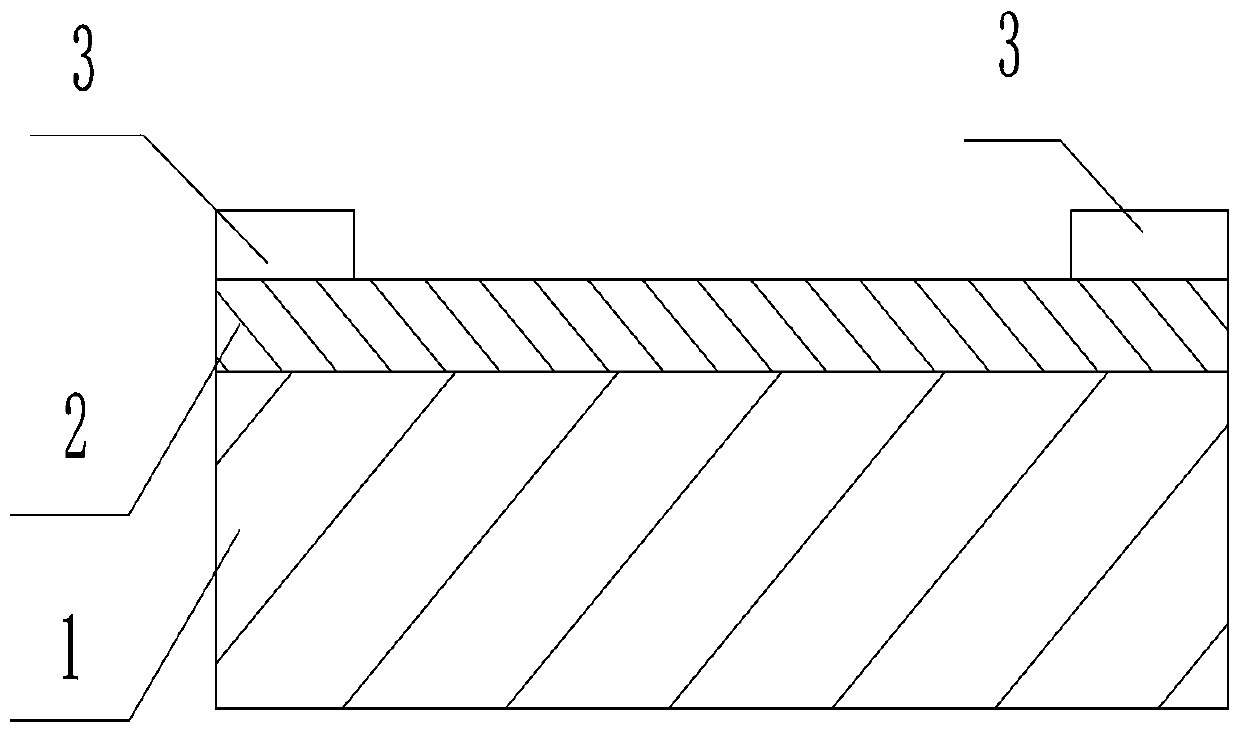

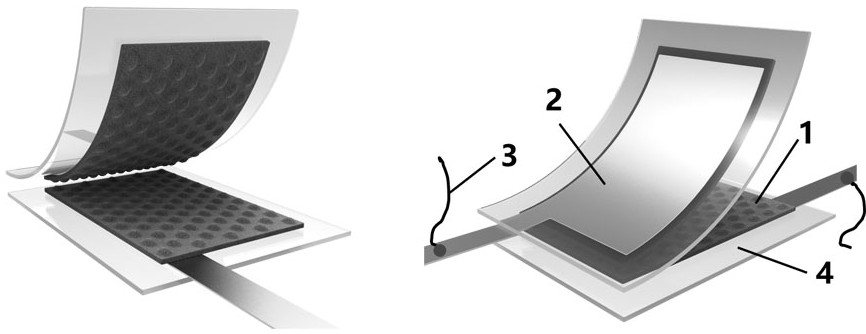

Piezoresistive electronic skin having pit structures and preparation method thereof

ActiveCN109374024AHigh sensitivityImprove stabilityCatheterRespiratory organ evaluationMicro structureElastomer

The invention, which belongs to the field of sensors, in particular relates to an electronic skin and a preparation method thereof. The invention provides a piezoresistive electronic skin comprising asensing layer; and sides with pit structures of two elastomer films having pit structures are laminated and assembled in opposite to assemble the sensing layer. According to the invention, since thesensing layer has a unique laminated pit micro structure, the sensitivity of the electronic skin is enhanced based on the micro structure; and the electronic skin has excellent stability and is capable of detecting various signals like a sound signal and a sliding signal as well as a body motion state and a physiological signal and the like. The electronic skin has the potential of application tobody health management.

Owner:SICHUAN UNIV

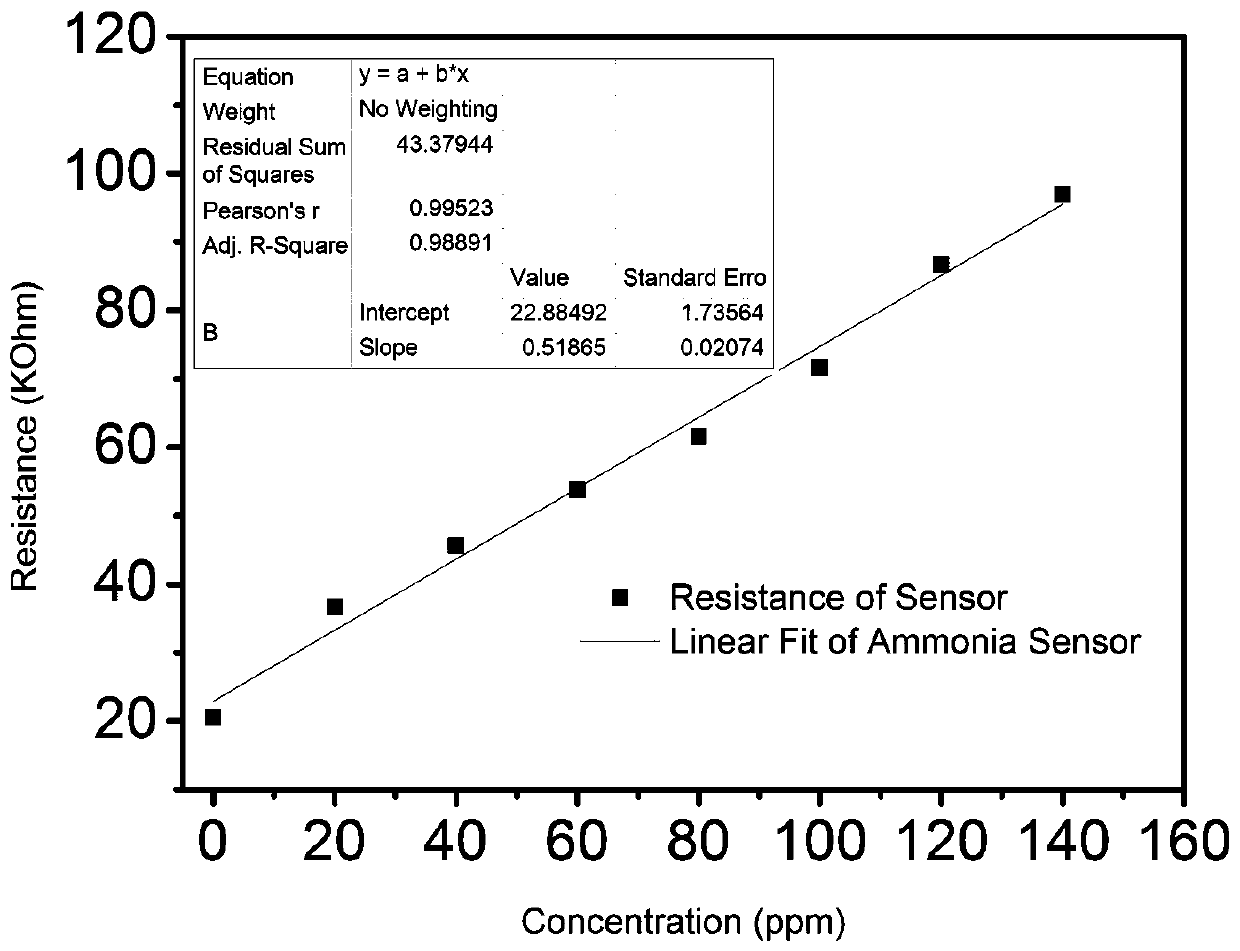

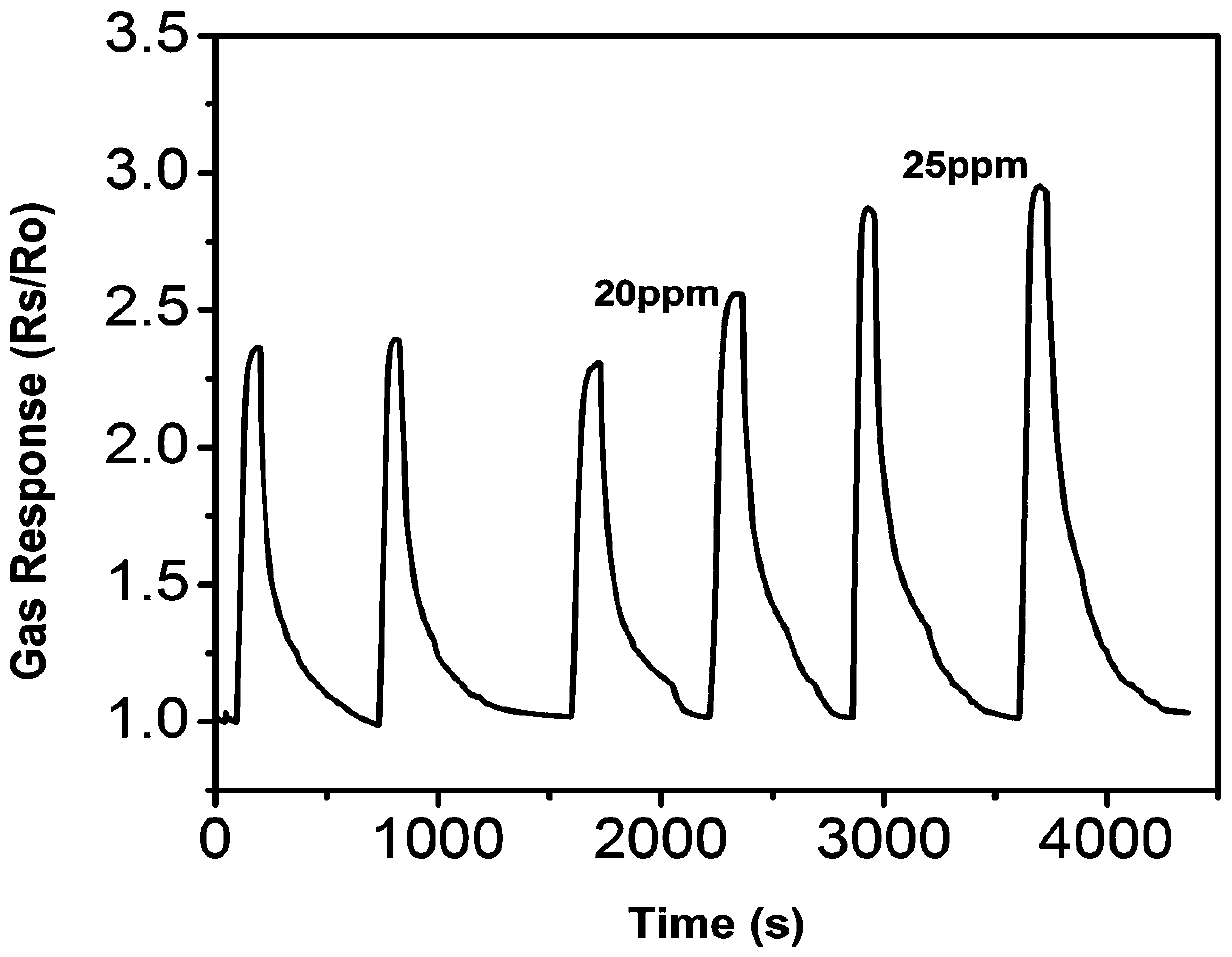

Protonic acid doped polyaniline material and room temperature ammonia gas sensor as well as preparation method

ActiveCN107674202AIncreased sensitivityGood choiceMaterial resistanceProtein coatingsBenzoic acidIce water

The invention provides a preparation method for protonic acid doped polyaniline, which comprises the following steps: at the room temperature, phenylamine and protonic acid are mixed to form a premixed solution, a template is added into the premixed solution, ultrasonic mixing and ice-water bath treatment are conducted sequentially, an ultrasonic dispersion solution is obtained, an oxidizing agentis dropwise added into the ultrasonic dispersion solution, standing reaction lasts for 20h-30h, and a protonic acid doped polyaniline material is prepared; the protonic acid may be oxalic acid, hydrochloric acid, sulfuric acid, citric acid, camphorsulfonic acid or benzoic acid; the molar ratio of the phenylamine, the protonic acid, the template and the oxidizing agent is 1:(2-3):(2-3):(5-10). Theinvention further provides a protonic acid doped polyaniline material and a room temperature ammonia gas sensor, and the room temperature ammonia gas sensor has relatively good sensibility and selectivity for ammonia gas, relatively low power consumption and relatively simple processing technology under the condition of room temperature.

Owner:郑州炜盛电子科技有限公司

Electromagnetic-radiation-resistant, waterproof and air-permeable film material, and preparation method and application thereof

ActiveCN107903435AImprove uniformity and compactnessImprove the activation effectLiquid/solution decomposition chemical coatingRadio frequencyIon exchange

The invention discloses an electromagnetic-radiation-resistant, waterproof and air-permeable film material. The preparation method for the electromagnetic-radiation-resistant, waterproof and air-permeable film material comprises the following steps: modifying a porous expanded polytetrafluoroethylene film through plasma treatment, then assembling a copolymer film with an active terminal group ontothe surface of the modified porous expanded polytetrafluoroethylene film and carrying out curing, loading active palladium chloride onto a side chain of the active copolymer film through ion exchange, and subjecting the surface-activated porous expanded polytetrafluoroethylene film to electroless deposition so as to obtain a surface-copperized porous expanded polytetrafluoroethylene film. The preparation method provided by the invention has simple operation, is economical and environment-friendly, and is applicable to industrial production. Meanwhile, the bonding force between the surface-copperized porous expanded polytetrafluoroethylene film and a copperized layer is strong; the copperized layer is uniform, has controllable density, can prevent electromagnetic radiation and has waterproof and air-permeable functions; and the material provided by the invention can be widely used for radiation protection of communication devices, industrial automation devices, radio-frequency and microwave medical devices, military equipment, high-voltage electrical apparatus and transportation tools under harsh conditions.

Owner:东莞市富颖电子材料有限公司

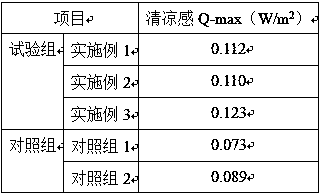

Multifunctional cooling fabric for summer

The invention discloses a multifunctional cooling fabric for summer. The fabric comprises, by weight, 40-60 parts of multifunctional cooling fibers, 5-15 parts of hemp fibers, 15-25 parts of cotton fibers and 8-15 parts of silk fibers. A production method of the fabric includes the following steps: preparing peppermint oil microcapsules, producing multifunctional cooling fiber slices, producing the multifunctional cooling fibers, and producing the multifunctional cooling fabric for summer. The multifunctional cooling fabric for summer has cooling, spirit-raising, bacterium preventing and inflammation eliminating effects, has the advantages of cooling during wearing, easiness in coloring, good sweat absorption effect, no irritating effect on skins, good gloss, good touch softness, smooth and soft hand feeling, and laundering durability; and the peppermint oil microcapsules on the surface of the fabric and in the fiber gaps of the fabric have a complete form and has no wall breaking phenomenon, so the slow release effect of the peppermint oil microcapsules can extend the cooling feeling of the fabric and the timeliness of the peppermint smell.

Owner:宁波北仑区川大普科电子科技有限公司

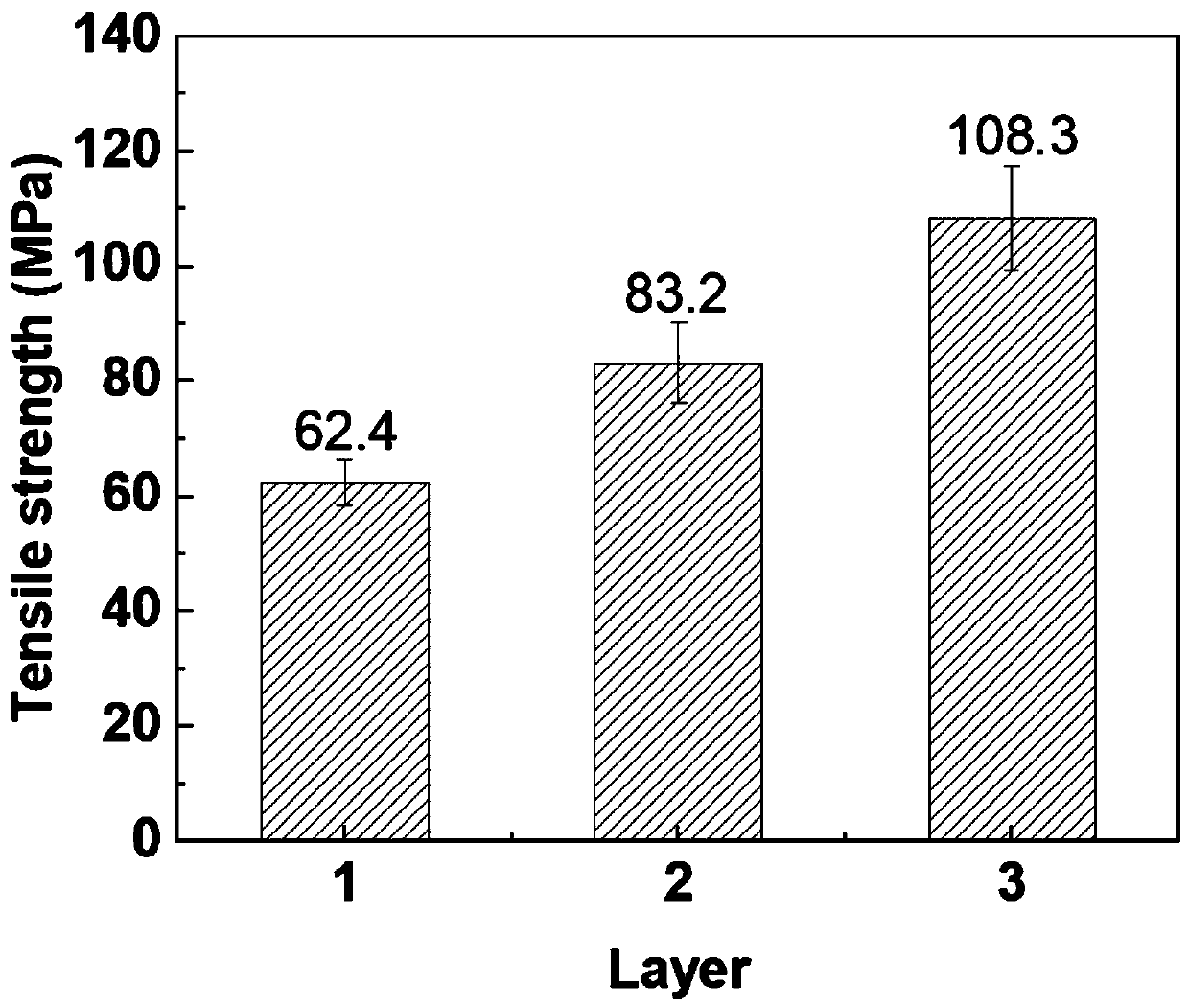

Preparation method of different stack layer carbon fiber cloth/TPU composite material with high electromagnetic shielding performance

ActiveCN110450488AHigh bonding strengthGood electromagnetic shieldingSynthetic resin layered productsFiberElectromagnetic shielding

The invention relates to a preparation method of a different stack layer carbon fiber cloth / TPU composite material with a high electromagnetic shielding performance. According to the preparation method, a silane coupling agent KH-550 is used to modify carbon fiber cloth, TPU particles are melted, cooled, and moulded to produce a TPU plate, and finally, a small pressure is applied to prepare the carbon fiber cloth / TPU composite material at a high temperature, and at the same time, the different stack layer carbon fiber cloth / TPU composite material is prepared. The obtained product has the characteristics of low cost, high strength, and excellent electromagnetic shielding performance.

Owner:SHANDONG UNIV

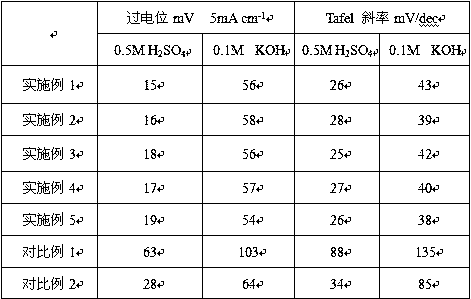

Preparation method for preparing tin bisulfide catalyst of hydrogen for fuel cell

InactiveCN108479807AGood effectGood dispersionPhysical/chemical process catalystsElectrodesBisulfideThiourea

The invention provides a preparation method for preparing a tin bisulfide catalyst of hydrogen for a fuel cell. The method comprises the steps that modified porous organic silicon is adopted as a substrate, molten metal tin and thiourea are subjected to an evaporation source reaction, evaporated tin atoms preferentially enter nanometer gaps of organic silicon to be combined with a modified group and react with thiourea to generate tin bisulfide nanoparticles, organic silicon loaded with the tin bisulfide nanoparticles is immersed in hydrofluoric acid for etching, a carbon-covering layer is deposited, the tin bisulfide nanoparticles are fixed in the gaps, and a high-dispersion carbon-covering tin bisulfide nanoparticle catalyst is obtained; therefore, the aggregation effect in the preparation method is lowered, and the defects that the tin bisulfide nanoparticle catalyst is serious in aggregation, and the catalytic performance is affected are overcome. Accordingly, the organic silicon on the surface is etched with hydrofluoric acid, a carbon source uniformly wraps the surface of tin bisulfide at high temperature, corrosion of electrolyte on tin bisulfide can be inhibited, and the stability of the catalyst in the electrolyte is improved.

Owner:CHENDU NEW KELI CHEM SCI CO LTD

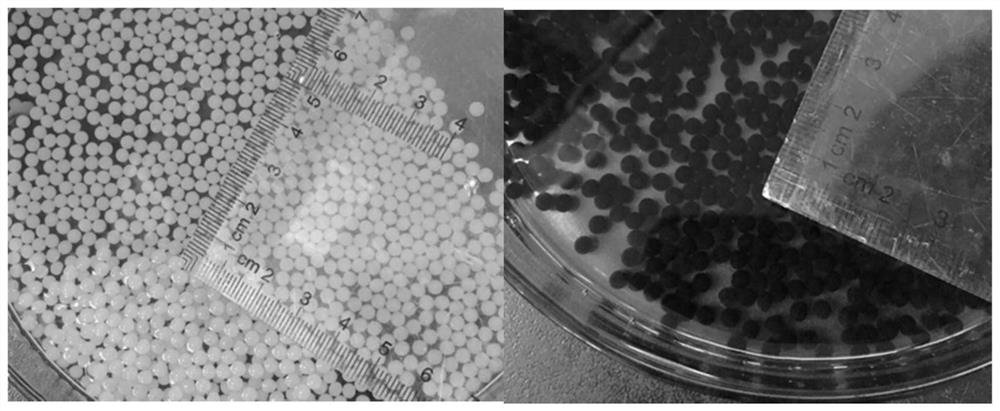

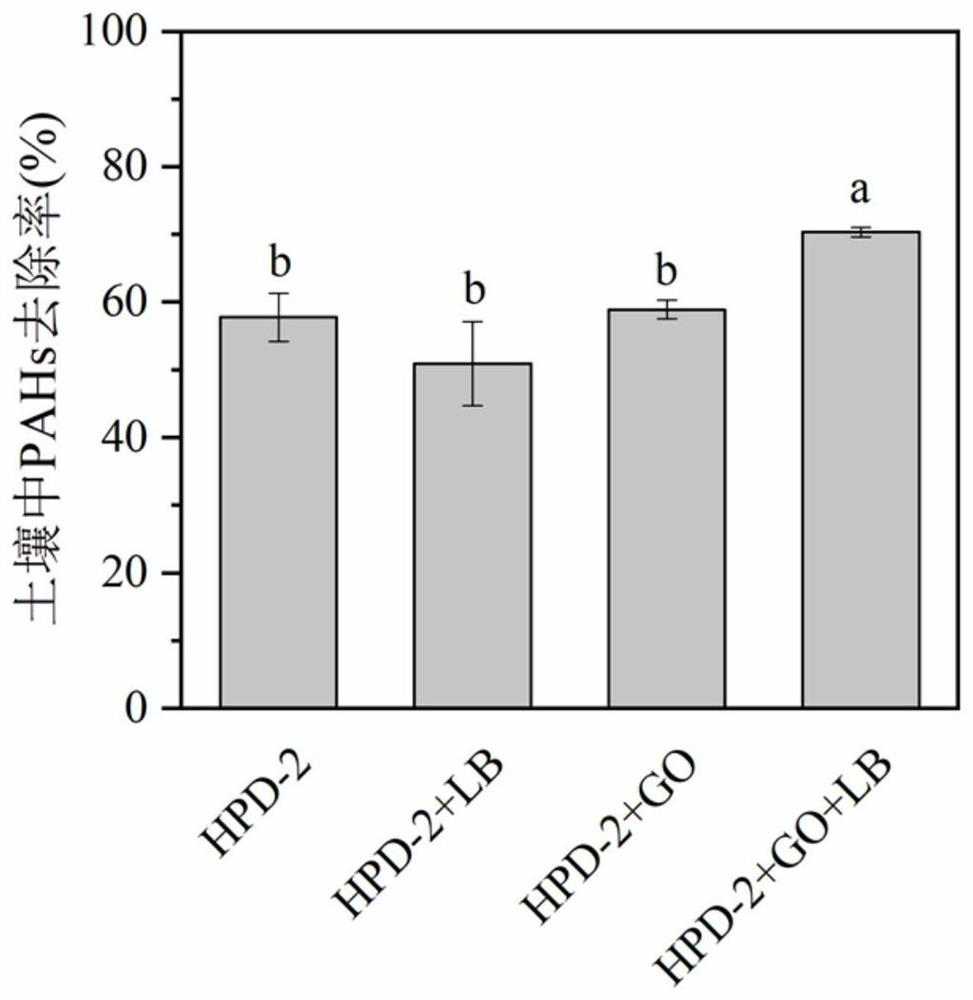

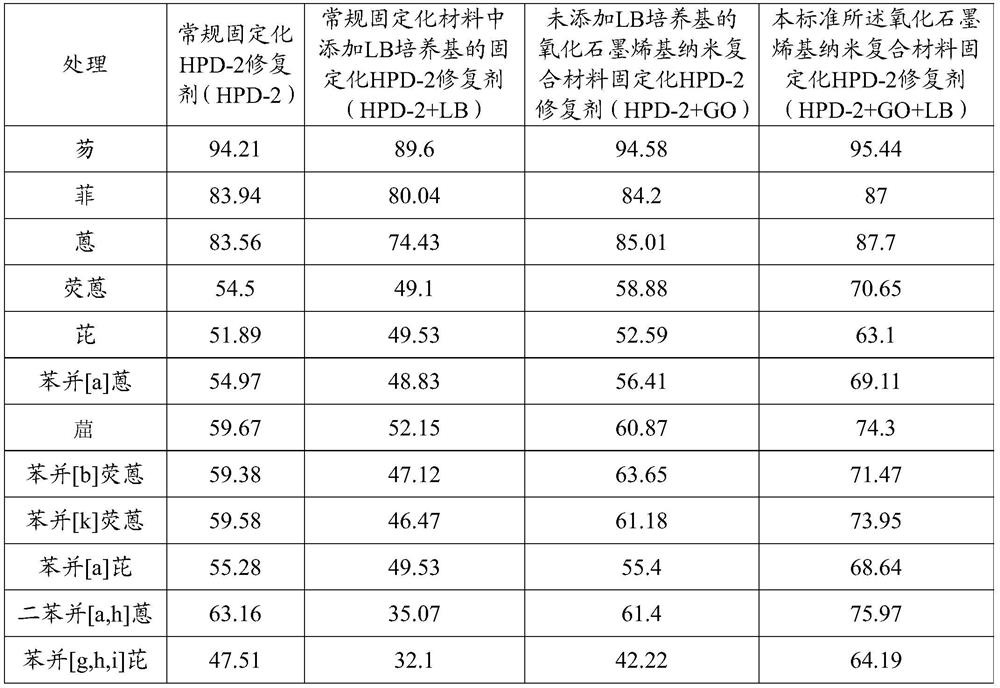

Nano-material immobilized microorganism remediation agent and preparation method and application thereof

ActiveCN111849956AHigh mechanical strengthExcellent mechanical propertiesContaminated soil reclamationMicroorganism based processesCross linkerBioremediation

The invention discloses a nano-material immobilized microorganism remediation agent and a preparation method and application thereof. The preparation method comprises the following steps of: (1) preparation of paracoccus aminovorans thalli; (2) preparation of an embedding agent graphene oxide-based nanocomposite material; (3) preparation of a cross-linking agent CaCl2 solution; and (4) preparationof the nano-material immobilized microorganism remediation agent. The graphene oxide-based nano-material immobilized microorganism remediation agent prepared by the preparation method disclosed by the invention is high in applicability to the environment, stable exertion of a degradation function of polycyclic aromatic hydrocarbon degradation microorganisms is guaranteed, the degradation efficiency of a traditional immobilized microorganism preparation is improved, and the microbial remediation period of polycyclic aromatic hydrocarbon contaminated soil is shortened; the preparation method issimple to operate, low in cost and good in effect, has a prospect of large-scale industrial production, is suitable for in-situ remediation of polycyclic aromatic hydrocarbon contaminated soil, and has no secondary pollution.

Owner:INST OF SOIL SCI CHINESE ACAD OF SCI

Preparation method of modified graphite cathode material of lithium-ion power battery

InactiveCN102544458AEasy dischargeImprove cycle performanceCell electrodesPower batteryPhysical chemistry

The invention aims at providing a preparation method of a graphite cathode material of a lithium-ion power battery. The preparation method comprises the steps of: firstly dissolving a soluble saccharide material into deionized water, then adding graphite and stirring the mixture violently to make the graphite more uniformly wrapped by the saccharide material, and finally enabling amorphous carbon after high temperature pyrolysis to totally wrap the surface of the graphite, thereby being more favorable for large-current discharge and improving the cycling performance of the battery. The preparation method is simple in process flow and low in production cost, the carbon can be wrapped relatively complete, and the graphite cathode material has the potentiality of large-scale industrial production.

Owner:中聚电池研究院有限公司

Dendrobium huoshanense-containing traditional Chinese medicinal composition having anti-fatigue effect, and preparation method thereof

InactiveCN106511777AGood for healthSuitable for large-scale industrial productionNervous disorderAntipyreticDendrobium huoshanenseSolvent

The invention relates to a Dendrobium huoshanense-containing traditional Chinese medicinal composition having an anti-fatigue effect, and a preparation method thereof. The composition can be used for making traditional Chinese medicinal preparations. The Dendrobium huoshanense-containing traditional Chinese medicinal composition having an anti-fatigue effect is prepared through combing the following raw materials: Dendrobium huoshanense, ginseng and Manyprickle Acathopanax Root according to a determined weight part ratio. The preparation method of the Dendrobium huoshanense-containing traditional Chinese medicinal composition having an anti-fatigue effect comprises the following steps: 1, selecting above traditional Chinese medicinal materials according to the determined weight part ratio, wherein the traditional Chinese medicinal materials are Dendrobium huoshanense, ginseng and Manyprickle Acathopanax Root; and 2, and processing the selected traditional Chinese medicinal materials: mixing the selected traditional Chinese medicinal materials, adding a solvent ethanol to prepare a mixed solution, carrying out refluxing extraction to extract medicine components dissolved in the mixed solution in order to obtain an extract liquid with medicinal values in the mixed liquid, filtering out medicine residues, and processing the obtained extract liquid to obtain the traditional Chinese medicinal composition.

Owner:威海恒基伟业信息科技发展有限公司

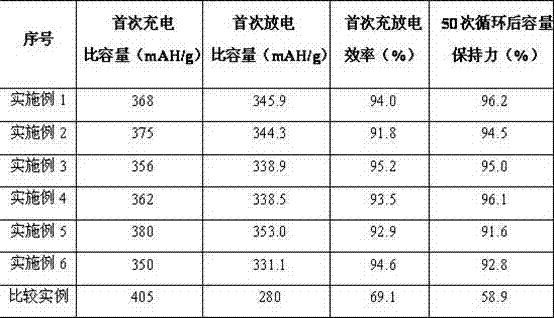

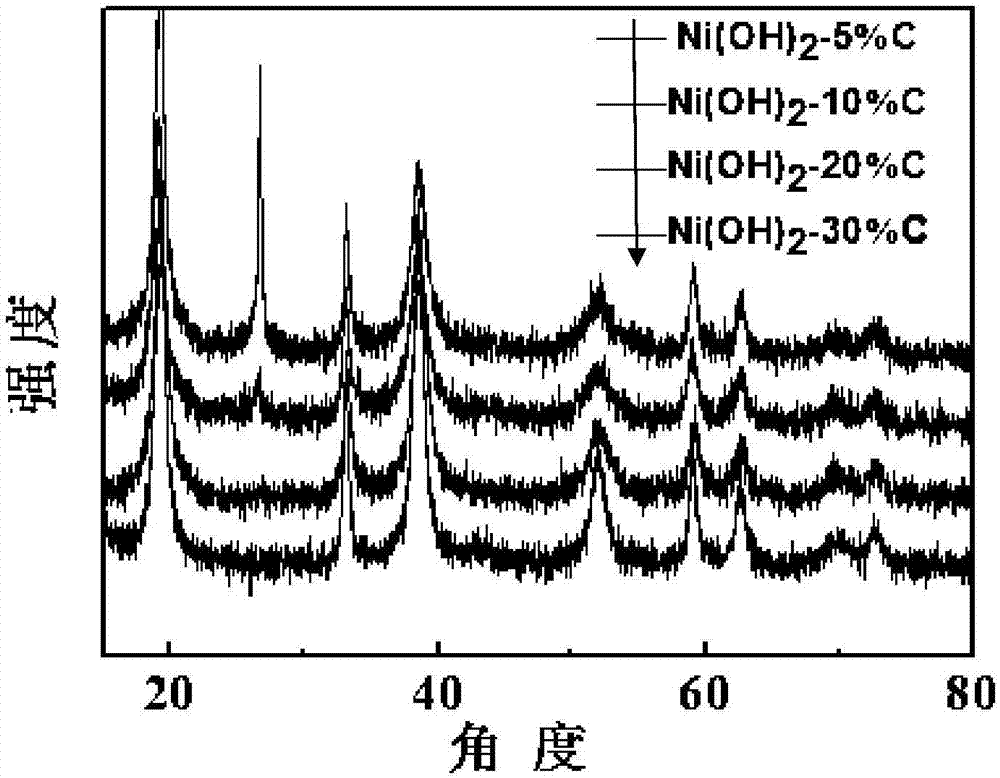

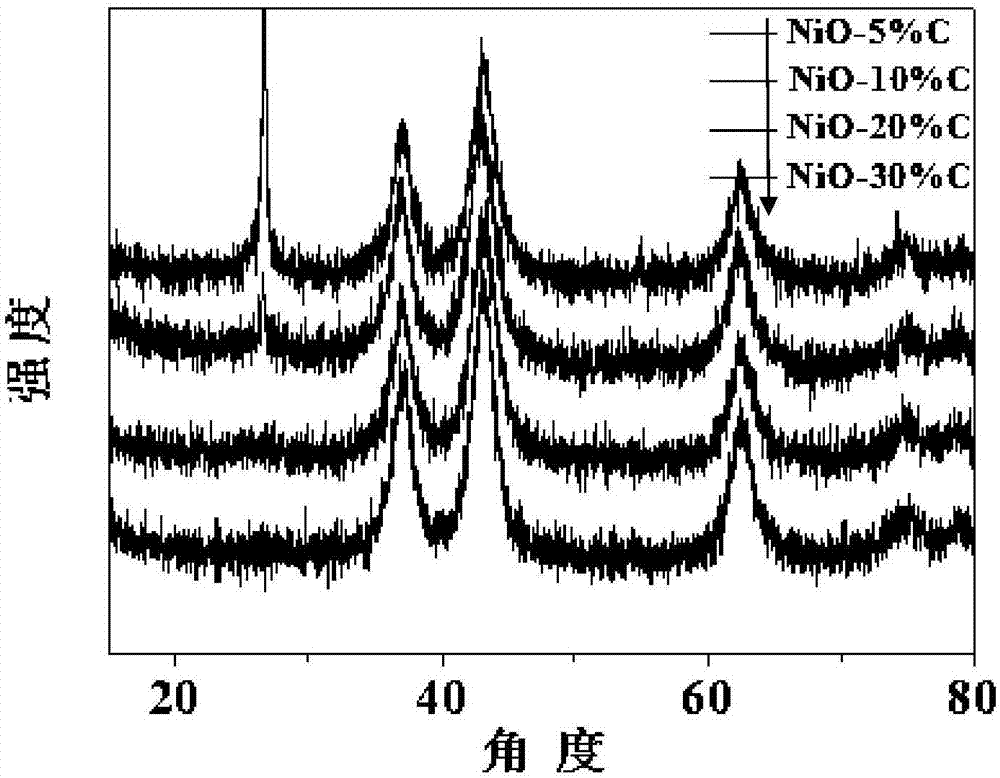

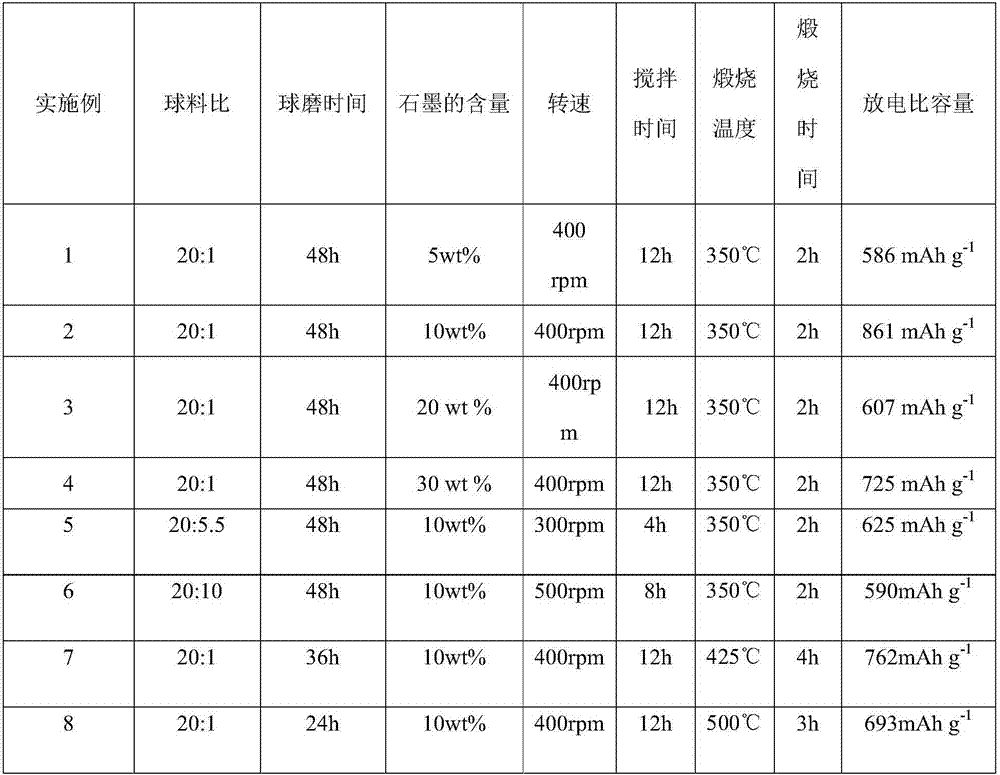

Nickel oxide/graphite composite nanomaterial used for lithium ion battery, and preparation method and application thereof

InactiveCN106920962AReduce the number of layersInhibition of agglomerationCell electrodesSecondary cellsNickel oxide hydroxideSodium-ion battery

Owner:SOUTH CHINA UNIV OF TECH

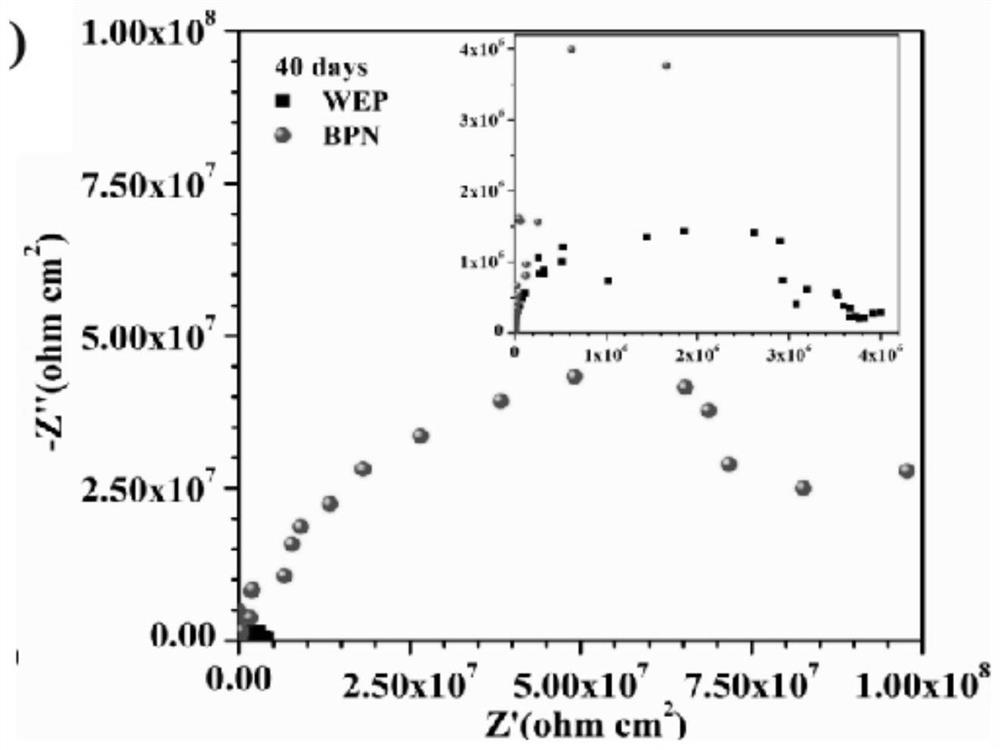

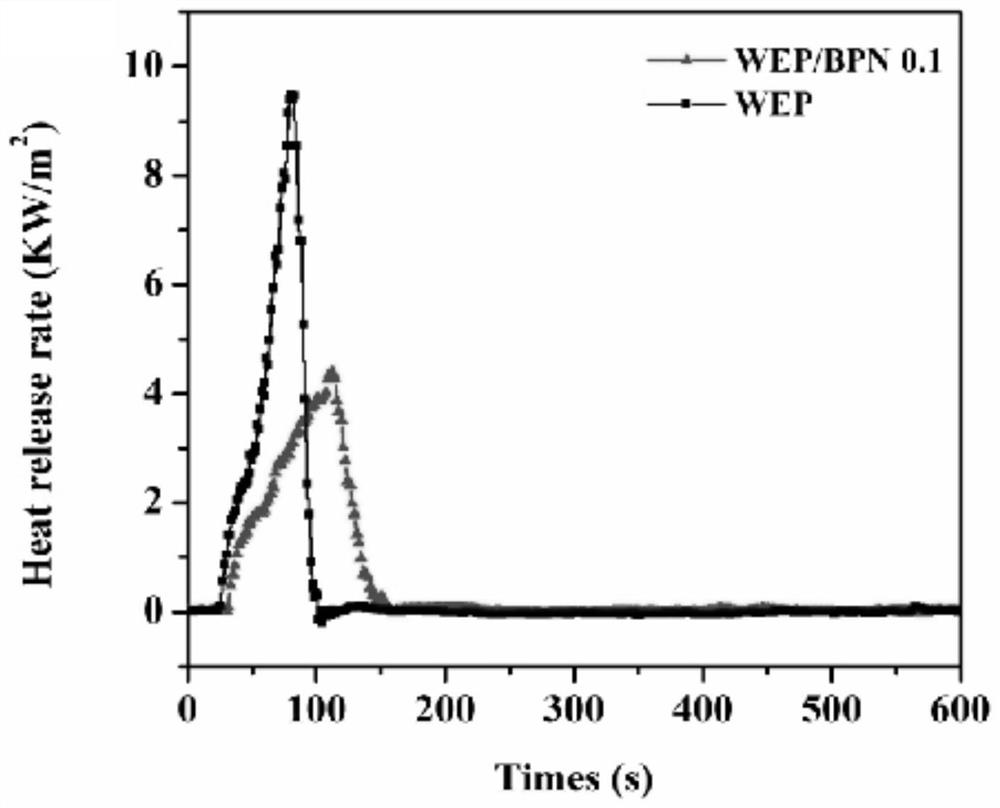

Anticorrosive and flame-retardant epoxy resin coating and preparation method thereof

PendingCN113388308AImprove penetrationImprove flame retardant performanceFireproof paintsAnti-corrosive paintsFlame resistancePolymer chemistry

The invention discloses an anticorrosive and flame-retardant epoxy resin coating and a preparation method thereof. The anticorrosive and flame-retardant epoxy resin coating is mainly prepared by ultrasonically dispersing aminated black phosphorus nanosheets obtained by ball-milling and stripping into waterborne epoxy resin. The aminated black phosphorus nano material with a lamellar structure is introduced into the coating, so that the prepared coating has good chemical corrosion resistance and flame retardance. The anticorrosive and flame-retardant epoxy resin coating is excellent in adhesion performance, high in hardness, good in anti-corrosion and flame-retardant effect and excellent in comprehensive performance. The preparation method is simple, is convenient for industrial production, can be used for preparing the epoxy resin anticorrosive and flame-retardant coating, and has a better application prospect in the field of anticorrosive and flame-retardant functional coatings.

Owner:KUNMING UNIV OF SCI & TECH

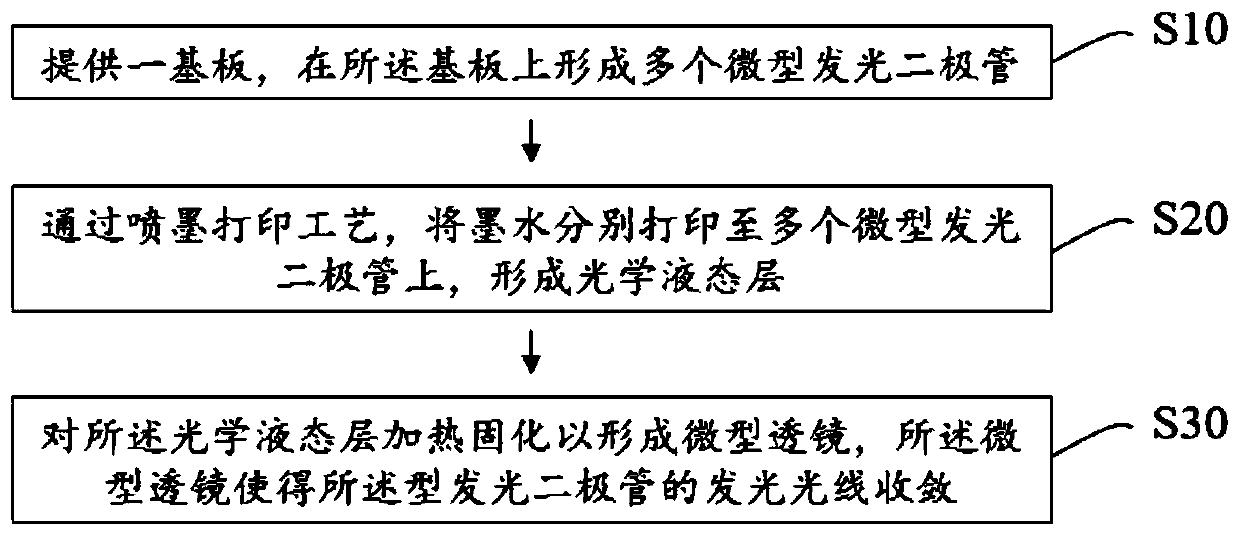

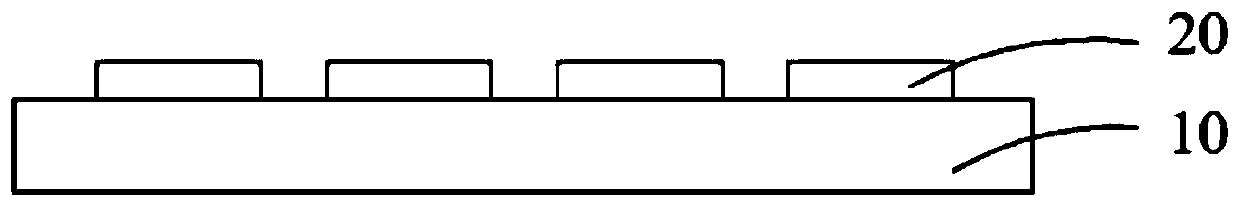

Backlight module, preparation method thereof and display device

InactiveCN111474768AReduce the half-value angle of light emissionReduce thicknessSolid-state devicesNon-linear opticsLiquid layerDisplay device

The invention discloses a backlight module, a preparation method thereof and a display device. The preparation method comprises the steps that a substrate is provided, and a plurality of micro light emitting diodes are formed on the substrate; ink is respectively printed onto the plurality of micro light emitting diodes through an ink-jet printing process to form an optical liquid layer; and a curing process is carried out on the optical liquid layer to form a micro lens, and the micro lens enables light emitted by the light emitting diode to converge. According to the method, the micro lens structure can be accurately formed on the micro light emitting diode through the ink-jet printing process, the production efficiency is high, raw materials are saved, and the method has high industrialization value.

Owner:TCL CHINA STAR OPTOELECTRONICS TECH CO LTD

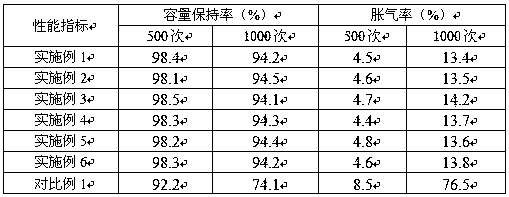

Lithium titanate coated positive electrode material for power battery and preparation method

InactiveCN109713270AGood effectImprove cycle performanceCell electrodesSecondary cellsPower batteryGraphene

The invention belongs to the technical field of technical lithium batteries, and provides a lithium titanate coated positive electrode material for a power battery and a preparation method. The methodcomprises the following steps: mixing a positive electrode material precursor with graphene oxide, performing heating to form a positive electrode material precursor coated with graphene oxide hydrogel, adding butyl titanate, performing reaction with a lithium source, and performing coating in a graphene oxide hydrogel grid to prepare the lithium titanate coated positive electrode material. Comparing with a material prepared through a traditional method, the prepared lithium titanate coated positive electrode material can effectively inhibit the gas expansion caused by contact between lithiumtitanate and an electrolyte because the surface of the positive electrode active material is uniformly coated with the formed graphene oxide / lithium titanate composite material. Meanwhile, the preparation process is simple, the process is easy to control, and the lithium titanate-coated positive electrode material has a good prospect in large-scale industrial production.

Owner:CHENDU NEW KELI CHEM SCI CO LTD

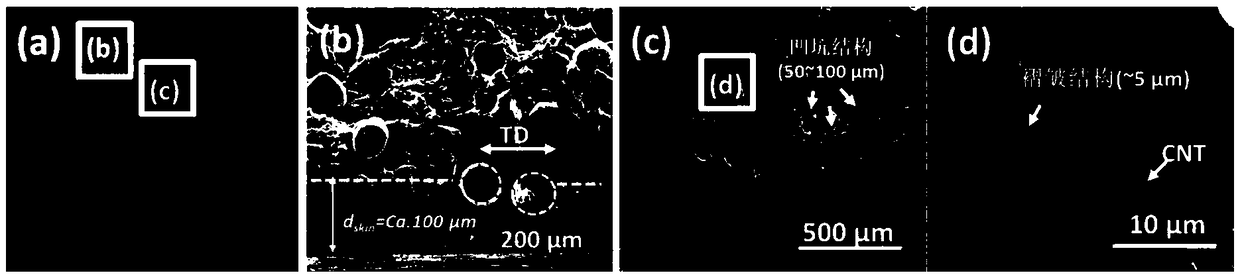

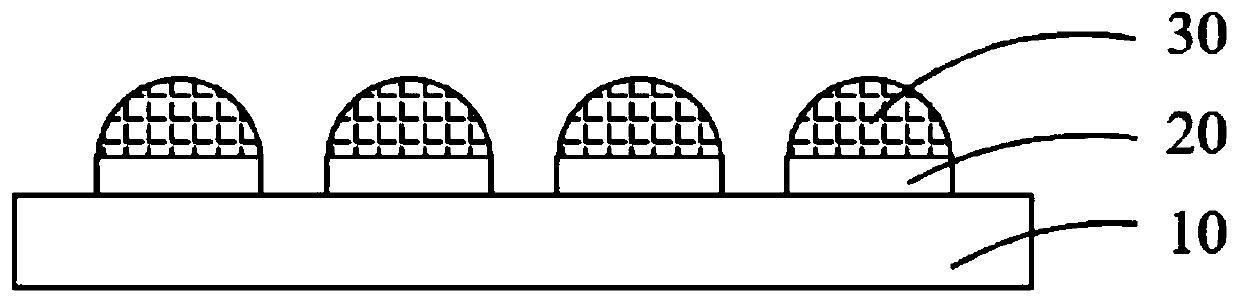

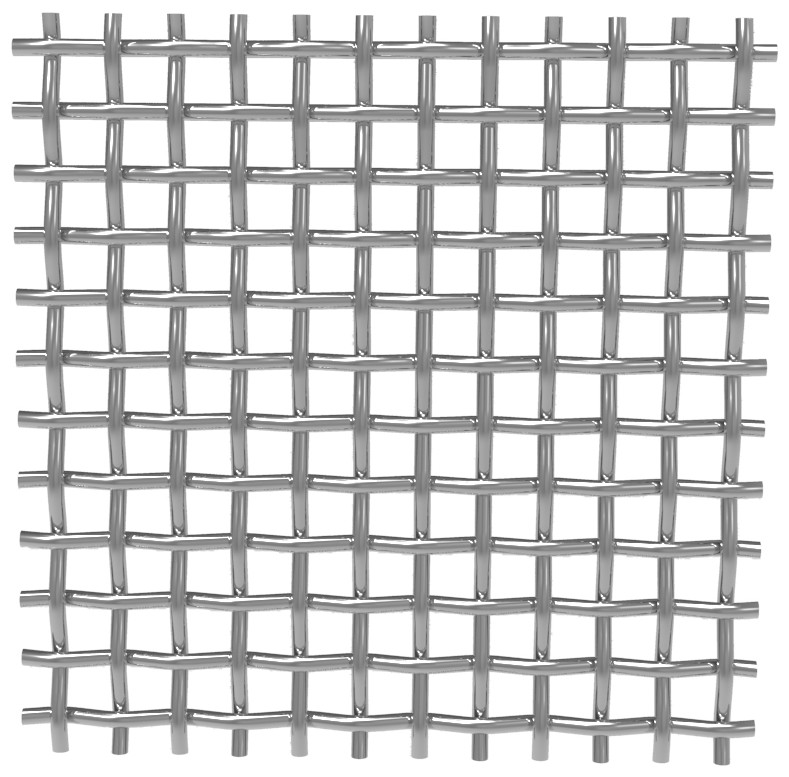

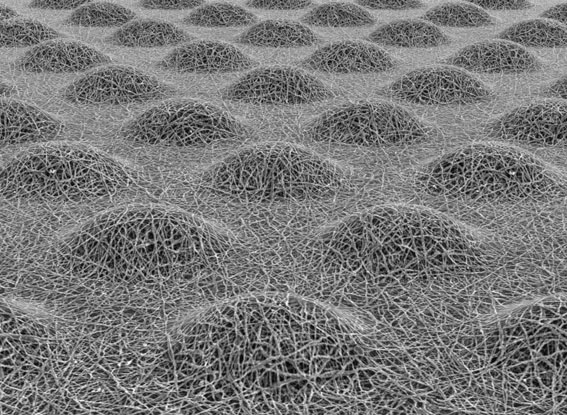

Elastomer film with multistage microstructure, preparation method of elastomer film and flexible pressure sensor comprising elastomer film

ActiveCN113503993AWith large-scale industrial productionCost reduction needsForce measurementElastomerPolymer science

The invention discloses an elastomer film with a multistage microstructure, a preparation method of the elastomer film and a flexible pressure sensor comprising the elastomer film, a process of combining a template method and electrostatic spinning is adopted, and the single side of the prepared elastomer film is provided with the multistage microstructure composed of randomly distributed fiber networks, and the requirement of low cost is met while stable and rapid preparation is realized. In addition, the electrostatic spinning technology is widely applied in industrial practice, and therefore the preparation method has the application prospect of large-scale industrial production. The prepared flexible pressure sensor is high in sensitivity (larger than 63.93 kPa <-1 >) and large in sensing range (larger than 160 kPa), not only has strong response to tiny vibration such as human pulse and vocal cord sounding, but also has stable response to large limb movement such as joint movement, shows good response in real-time monitoring of pressure, and is huge in application potential.

Owner:TIANJIN UNIV OF SCI & TECH

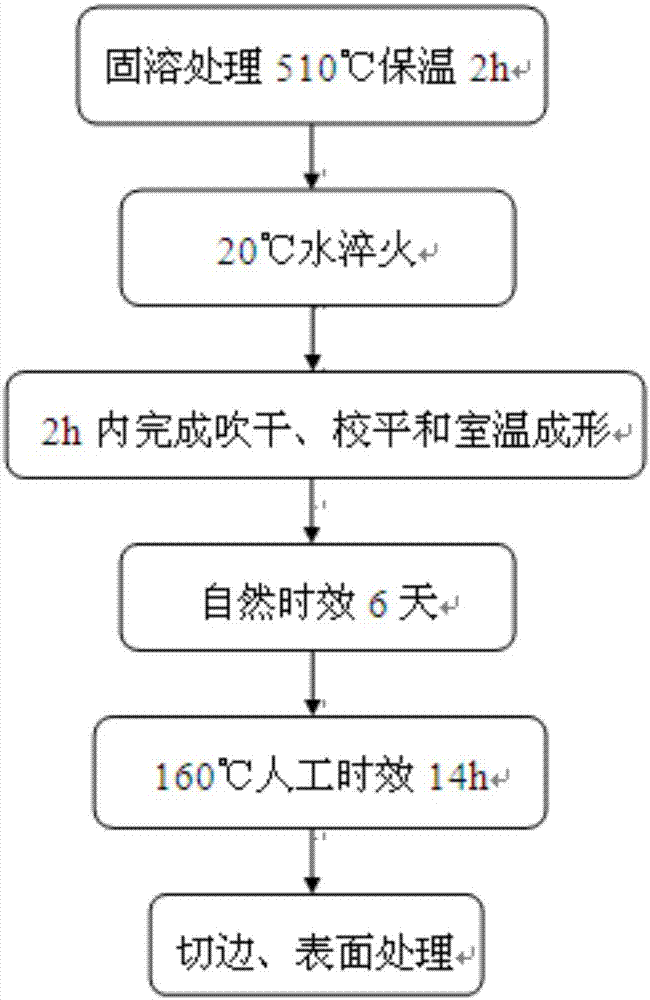

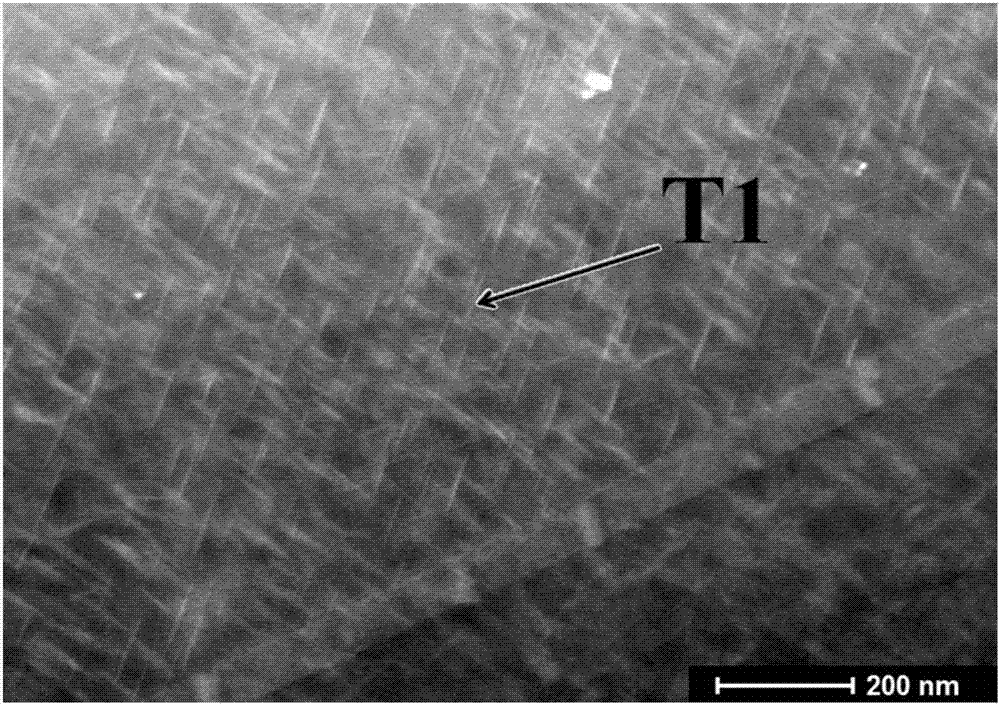

Room-temperature forming method for 2198 aluminum-lithium alloy panel

The invention provides a room-temperature forming method for a 2198 aluminum-lithium alloy panel. The method includes the following steps that firstly, solution treatment is conducted, wherein a panel is placed in a heating furnace, and the heat preservation time is controlled; secondly, quenching treatment is conducted, wherein the panel subjected to solution treatment is rapidly transferred into low-temperature water, the transfer time is strictly controlled, and it is ensured that the whole panel is completely quenched; thirdly, room-temperature forming is conducted, wherein the panel is rapidly taken out of the water, and leveling and forming of the panel are completed within a short period of time; fourthly, natural aging is conducted, and the panel stands for 3-9 days; fifthly, manual aging is conducted, wherein a part is placed in the heating furnace, and heat preservation is conducted for a certain period of time; and sixthly, the part is taken out and subjected to edge cutting and surface treatment, and a 2198 aluminum-lithium alloy panel part is obtained. According to the room-temperature forming method, by conducting room-temperature forming before aging treatment is conducted on the 2198 aluminum-lithium alloy panel, the plastic forming and the necessary pre-forming before aging are combined together, the difficulty that plasticity of a 2198 aluminum-lithium alloy is poor is avoided, strength of the part is increased, the processing cost is effectively reduced, the geometric precision of the part is improved, and potential of large-scale industrialized production is achieved.

Owner:SHENYANG AEROSPACE UNIVERSITY

Blue-light and near ultraviolet excitation type hydrothermal one-dimensional red nanometer fluorescent powder preparation method

InactiveCN104877681AShort manufacturing cycleQuality improvementLuminescent compositionsPhysical chemistryNear ultraviolet

The invention discloses a hydrothermal nanometer fluorescent powder preparation method, belongs to the technical field of fluorescent powder preparation, and aims to provide a one-dimensional red nanometer fluorescent powder preparation method. The hydrothermal preparation method includes the steps of determining a molar ratio of components according to a general chemical formula Ca(1-z)RwOu:zEu3+ or MyCa(1-x-y)RwOu:xEu3+, and preparing various raw materials proportionally; dripping the raw materials into a certain concentration of ammonium bicarbonate solution at a certain speed, stirring with aging for 24 hours, and performing water washing for filtering for 4 times continuously to obtain a precursor; placing the obtained precursor into a mixed solvent of absolute ethyl alcohol and water to obtain a mixture, pouring the mixture into a stainless steel autoclave with a silver liner, and heating to 350 DEG C at the speed of 1.5 DEG C / min; keeping the temperature at 350 DEG C for 4 hours, powering off, cooling to a room temperature naturally, taking an obtained product out, and subjecting the product to water washing, suction filtering and drying to obtain the nanometer fluorescent powder. The blue-light and near ultraviolet excitation type hydrothermal one-dimensional red nanometer fluorescent powder preparation method has the advantages of low cost and safety in operation, and the prepared one-dimensional red nanometer fluorescent powder is regular in shape and small in granularity.

Owner:CHENGDU SIKETAI TECH

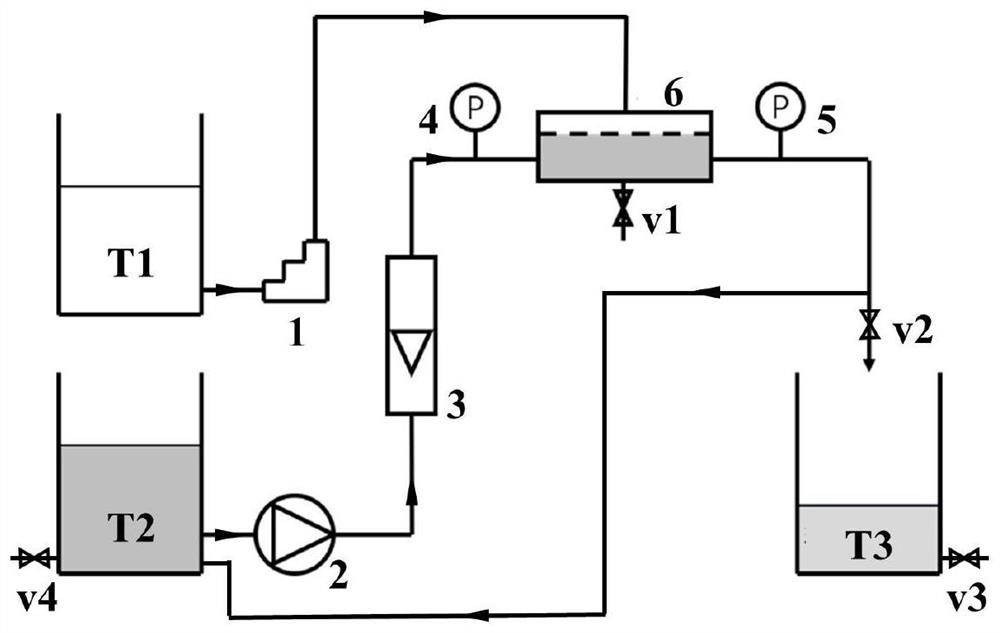

Method for emulsifying oil product through membrane

PendingCN114471212AMeet the preparation requirements of particle sizeEasy to manufactureMixing methodsTransportation and packagingCarbide siliconOil emulsion

The invention relates to a method for emulsifying an oil product by using a membrane, which is characterized in that a high-flux silicon carbide membrane with a specific structure after surface property regulation is adopted as an emulsifying medium, water is adopted as a dispersion phase, an oil product is adopted as a continuous phase, the dispersion phase passes through ceramic membrane holes at low pressure and high flux, and the oil product is emulsified under the action of shearing force formed by continuous phase flowing. The dispersed phase leaves the surface of the membrane and enters the continuous phase, so that water and oil are fully mixed and dissolved, and water-in-oil emulsion with uniform particle size is formed. The method has the advantages of high flux, low energy consumption, simple device and the like, is a way for efficiently preparing the water-in-oil emulsion, and is suitable for large-scale industrial application, and liquid drop coalescence can be reduced and the emulsion stability can be improved under the condition that an emulsifier is not added by regulating and controlling the surface properties and operation parameters of the membrane.

Owner:NANJING UNIV OF TECH +1

Amorphous manganite/graphite composite nano material and preparation method and application thereof to lithium ion battery

ActiveCN106299290AAlleviate volume changesInhibition of agglomerationCell electrodesElectricityPower flow

The invention discloses an amorphous manganite / graphite composite nano material and a preparation method and application thereof to a lithium ion battery, and belongs to the technical field of lithium ion battery materials. The preparation method includes the steps that graphite and potassium permanganate are ball-milled in an aqueous solution, and then washing, ultrasonic treatment and drying are conducted to obtain the amorphous manganite / graphite composite nano material. The mass fraction of graphite in the obtained material is 5.2-58.6%, when the material is used for the negative pole of the lithium ion battery, the material has excellent electric performance, after circulation is conducted for 250 turns under the current density of 200 mA g<-1>, the material can still keep the reversible capacity of 977 mA h g <-1>, and under the condition of large current density (1000 mA g<-1>), after circulation is conducted for 200 turns, the reversible capacity can still be kept 300 mA h g<-1> or above.

Owner:GUANGDONG ORIENT RESIN

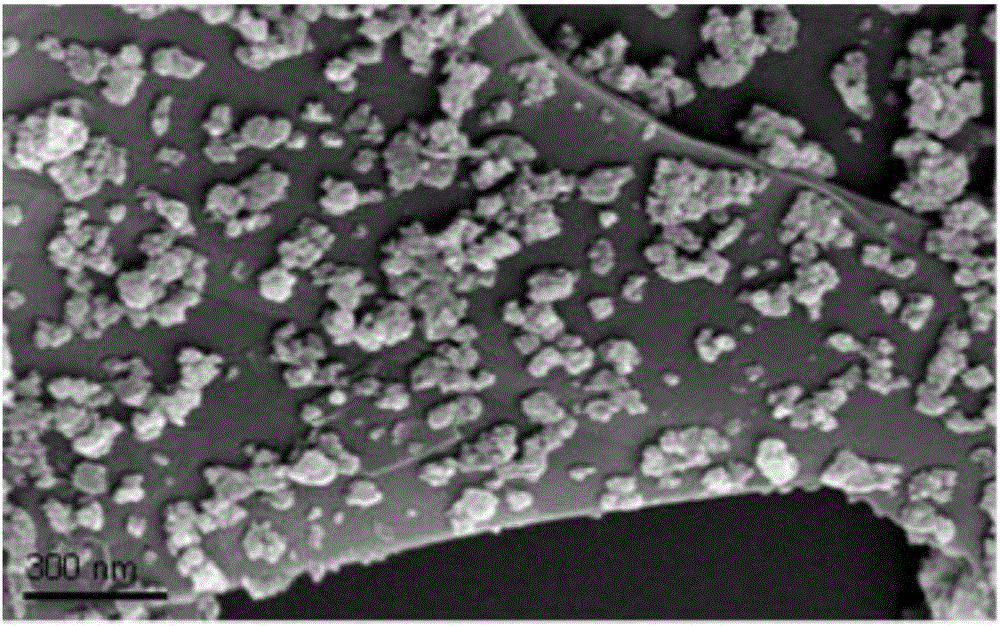

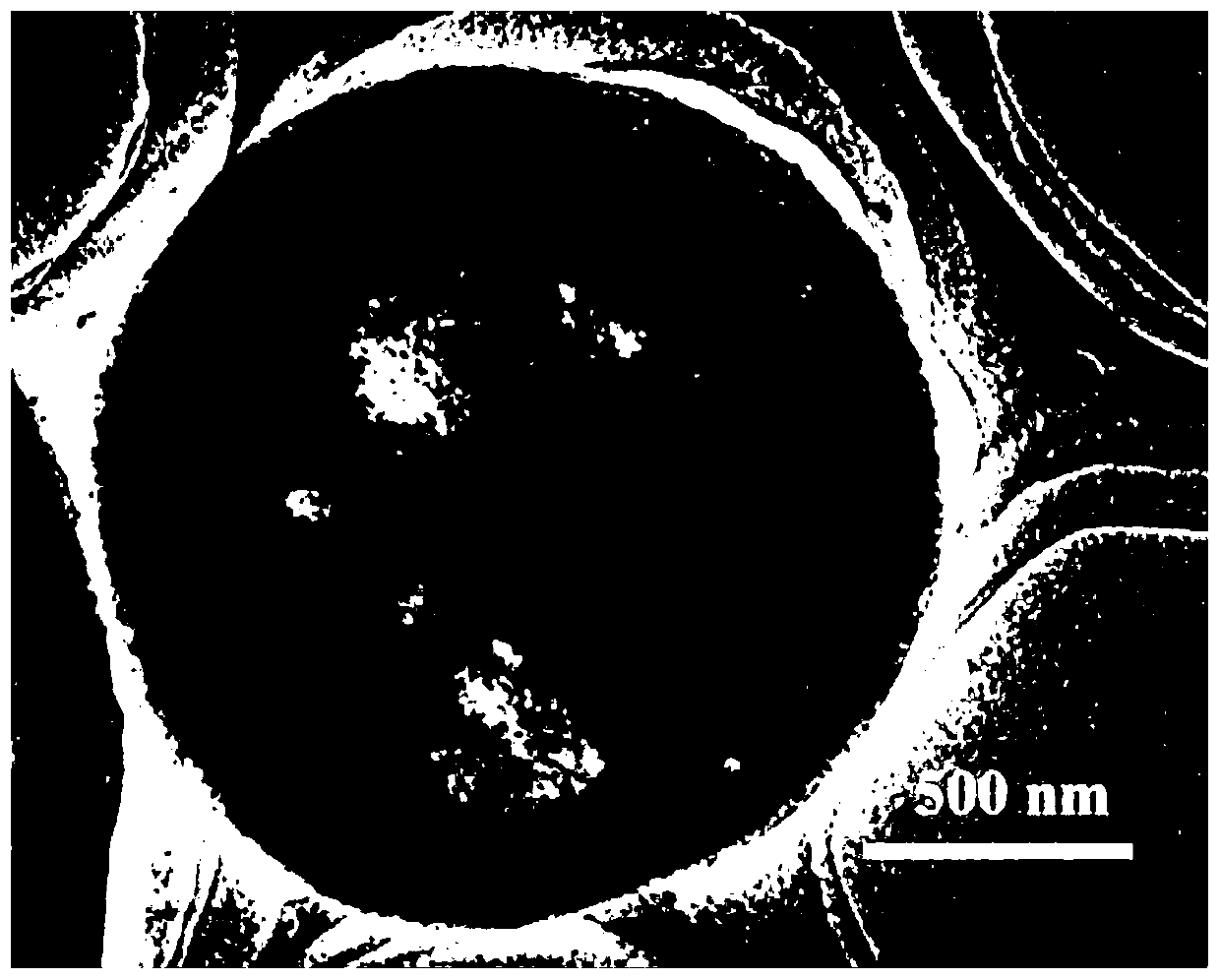

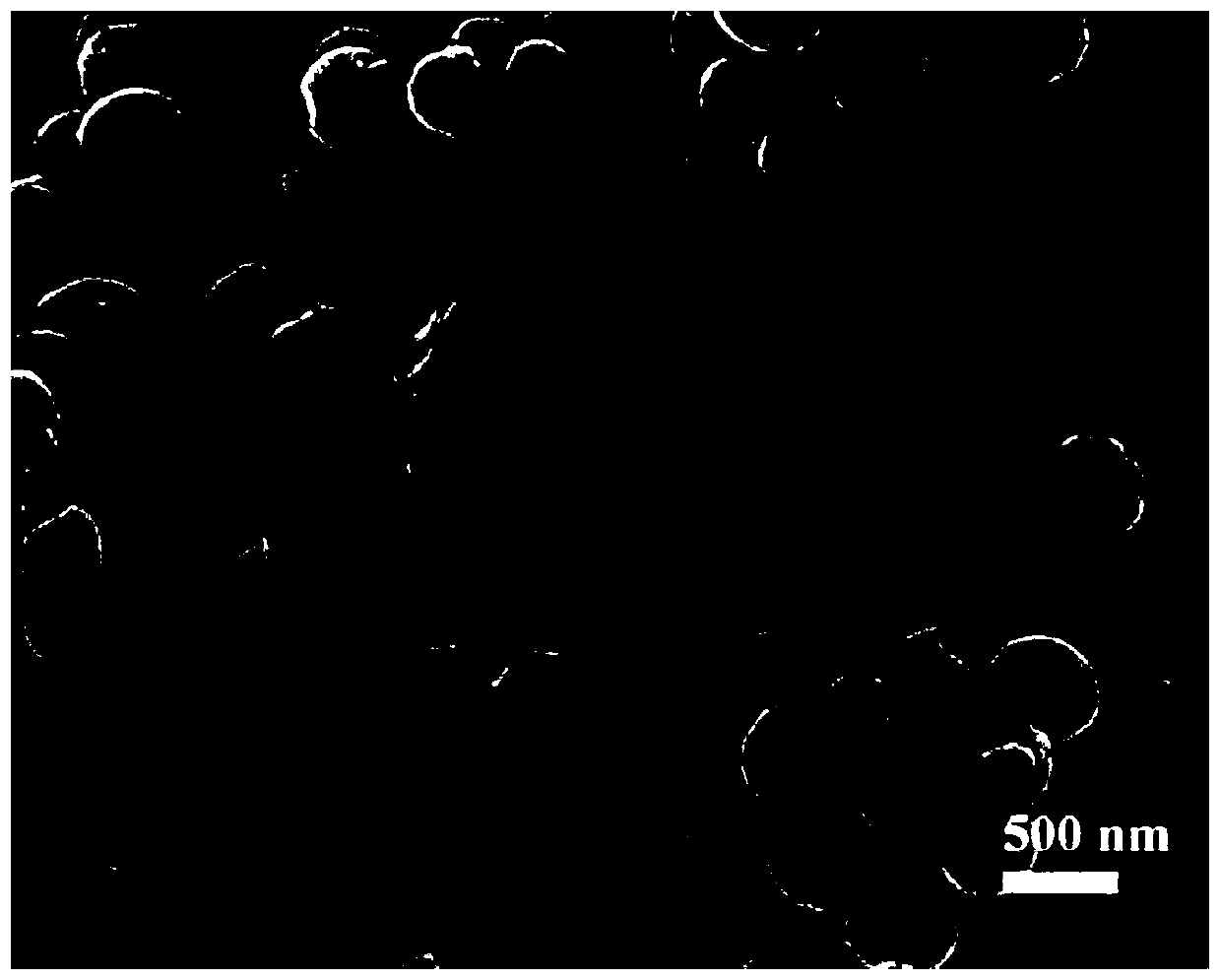

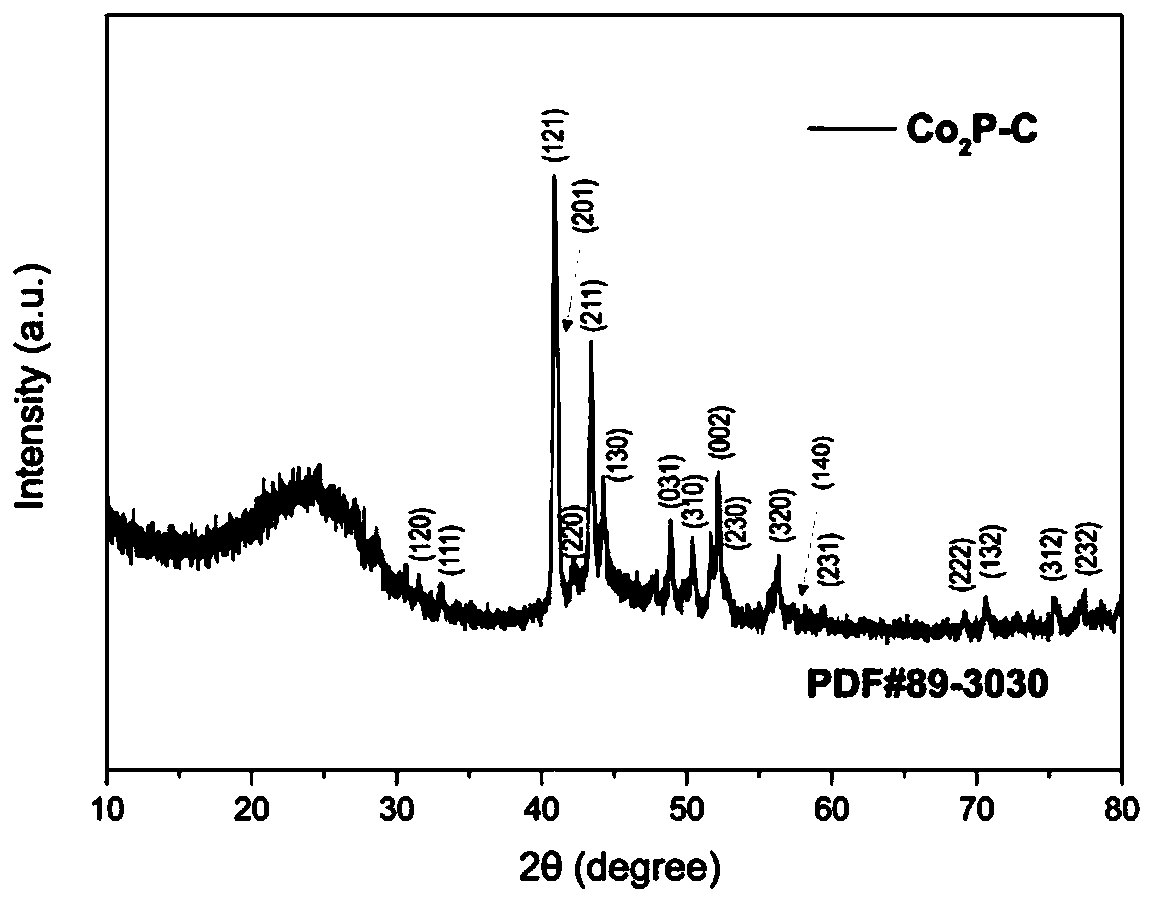

A supported transition metal phosphide, its preparation method and its application in catalytic hydrogen production

ActiveCN108452817BReduce consumptionWide variety of sourcesPhysical/chemical process catalystsChemical industryCarbonizationReaction step

Owner:INST OF CHEM CHINESE ACAD OF SCI

Fuel-cell catalyst doping with porous diamond carrier and preparation method

InactiveCN108777310AHigh catalytic activityImprove structural stabilityMaterial nanotechnologyCell electrodesAlloy compositeOxidation resistant

The invention provides a fuel-cell catalyst doping with a porous diamond carrier and a preparation method. A flaky metal electrode material is used as a substrate; an arc plasma is used for depositinga diamond film on a surface layer; a used gas source is hydrogen, argon and methane; a mixed gas of the hydrogen and the methane is sprayed through a nozzle in a plasma muzzle; the argon and a gas-state / steam-state doping source is sprayed through a nozzle outside the muzzle by loading nano platinum / tin alloy powder, and a composite material doping with porous diamond / alloy is formed on the surface layer of the substrate. According to the fuel-cell catalyst doping with the porous diamond carrier and a preparation method provided by the invention, the porous nano diamond is used as a carrier for coating the nano alloy, and the porous nano diamond is used as the carrier so as to have high oxidation resistance and good active metal dipersibility, so that the stability of the catalyst is improved, and the defect that the catalytic activity of the catalyst is further reduced since the active metal dipersibility cannot be controlled when current nano diamond particles are used as the carrier is further overcome.

Owner:CHENDU NEW KELI CHEM SCI CO LTD

Preparation method of blue light and near ultraviolet excitation type one-dimensional red nano fluorescent powder

ActiveCN103087711AImprove uniformityIncrease the doping concentrationGas discharge lamp usageLuminescent compositionsMaterials preparationNear ultraviolet

The invention provides a preparation method of blue light and near ultraviolet excitation type one-dimensional red nano fluorescent powder, belonging to the technical field of luminous material preparation. The method comprises the following steps of: preparing all raw materials according to the molar ratio of the components determined by the chemical general formula of red nano fluorescent powder Ca(1-z)RwOu:zEu<3+> or MyCa(1-x-y)RwOu:xEu<3+>, wherein R is at least one of Ge and Si, and M in an M source is at least one of Li, Na, K, Sr, Mg and Al; adding water into the raw materials and performing ultrasonic treatment for 30-60 minutes; transferring the product into a reaction kettle, and controlling the filling degree of the reaction kettle to be 60-85%; preserving heat at 100-200 DEG C for 1-48 hours; cooling and filtering; and drying the filter residue at 60-90 DEG C to obtain one-dimensional red nano fluorescent powder. The method provided by the invention has the advantages of simple preparation technology, safety and controllability, low preparation temperature, low energy consumption and uniform distribution of the components, and is suitable for industrial production.

Owner:CENT SOUTH UNIV

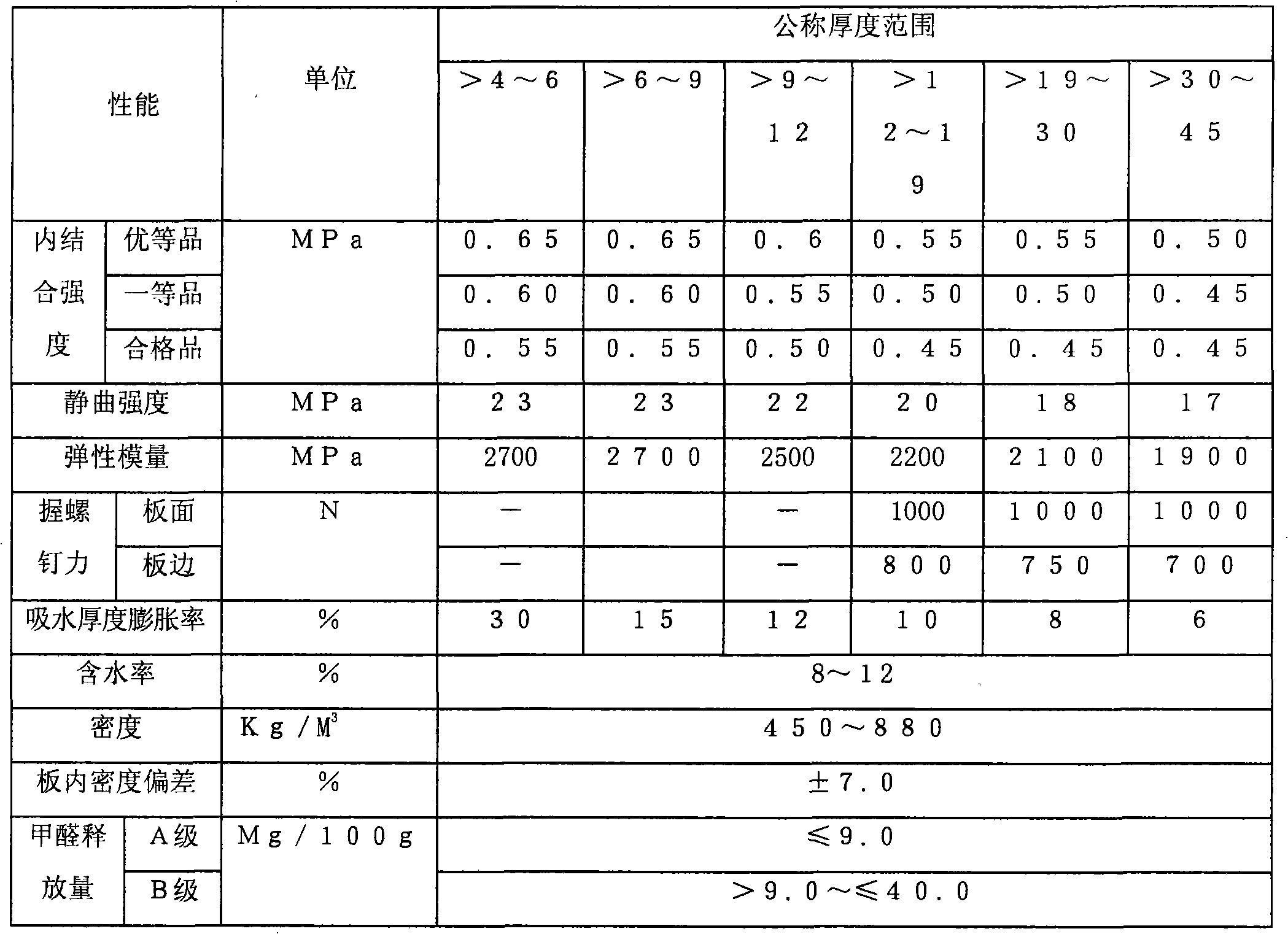

Production method of color make-up board

InactiveCN101830019ASolve the needs of production materialsNo pollutionWood working apparatusEmulsionPolyvinyl acetate

The invention relates to a production method of a color make-up board, which can effectively solve the utilization problem of wastes generated in building and furniture board and wood processing. The method comprises the following steps of: drying and maintaining paulownia batten rough boards, and then shaving the four surfaces; pouring a polyvinyl acetate emulsion into a container; adding urea-formaldehyde glues and then adding potassium chloride; evenly stirring to form a mixed glue solution; filling the mixed glue solution in a felt-board machine; then putting the paulownia batten rough boards in the mixed glue solution; pressurizing the four surfaces so as to glue rough paulownia batten boards together; then sanding the rough paulownia batten boards into medium-density blank flats; coating the polyvinyl acetate emulsion layers on the upper surface and the lower surface of the blank flats, and laminating into semi-finished slabs; putting color pasters in the polyvinyl acetate emulsion for dipping and then taking the color pasters out; adhering the colour pasters onto both surfaces of the semi-finished slabs; heating so as to thermally adhering the semi-finished slabs and the color pasters together to form the integral color make-up board. The invention has simple method and low production cost, can not generate pollution to air, water sources and soil and is an innovation in artificial board industry.

Owner:HENAN TONGLIN WOOD

A kind of amorphous manganese oxide/graphite composite nanomaterial and its preparation method and application in lithium ion battery

ActiveCN106299290BAlleviate volume changesInhibition of agglomerationCell electrodesElectrical batteryPotassium manganate

The invention discloses an amorphous manganite / graphite composite nano material and a preparation method and application thereof to a lithium ion battery, and belongs to the technical field of lithium ion battery materials. The preparation method includes the steps that graphite and potassium permanganate are ball-milled in an aqueous solution, and then washing, ultrasonic treatment and drying are conducted to obtain the amorphous manganite / graphite composite nano material. The mass fraction of graphite in the obtained material is 5.2-58.6%, when the material is used for the negative pole of the lithium ion battery, the material has excellent electric performance, after circulation is conducted for 250 turns under the current density of 200 mA g<-1>, the material can still keep the reversible capacity of 977 mA h g <-1>, and under the condition of large current density (1000 mA g<-1>), after circulation is conducted for 200 turns, the reversible capacity can still be kept 300 mA h g<-1> or above.

Owner:GUANGDONG ORIENT RESIN

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com