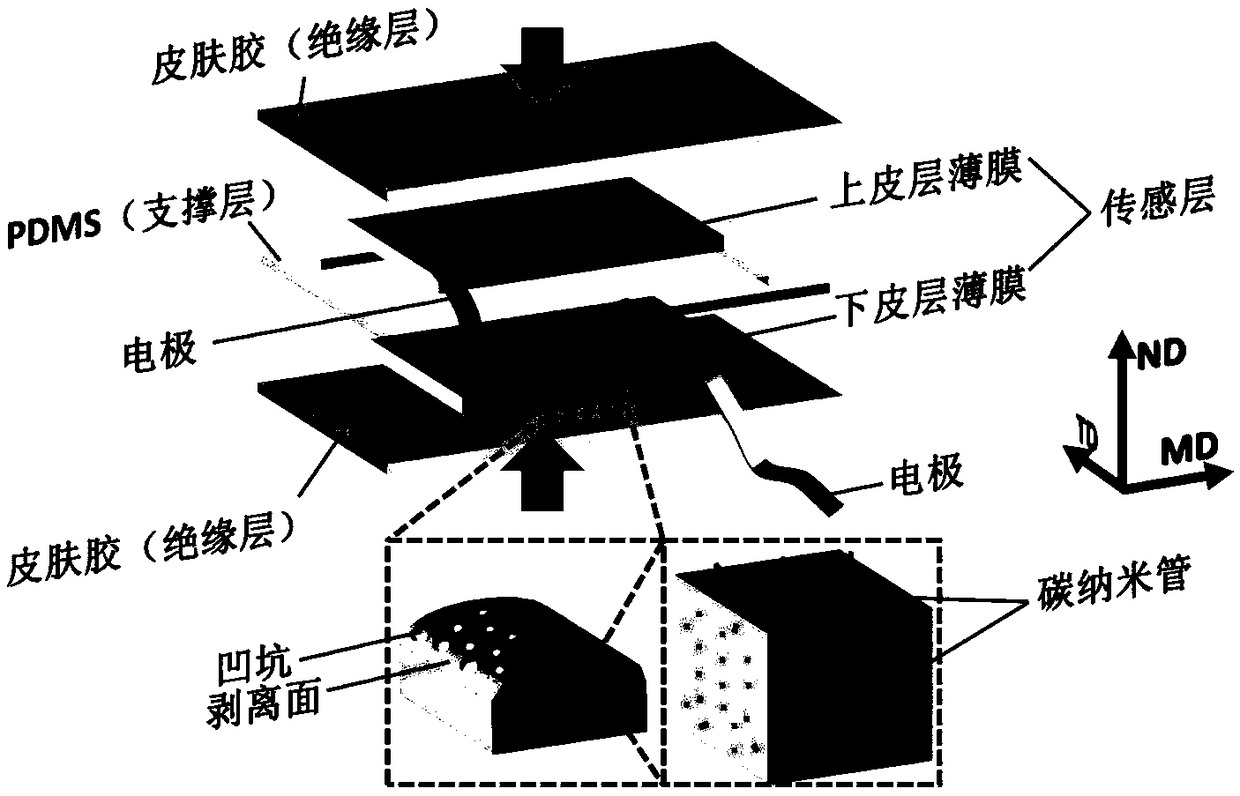

Piezoresistive electronic skin having pit structures and preparation method thereof

An electronic skin and piezoresistive technology, applied in the field of sensors, can solve the problems of high cost, unfriendly environment, and long production cycle, and achieve the effects of low cost and energy consumption, excellent stability, and high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

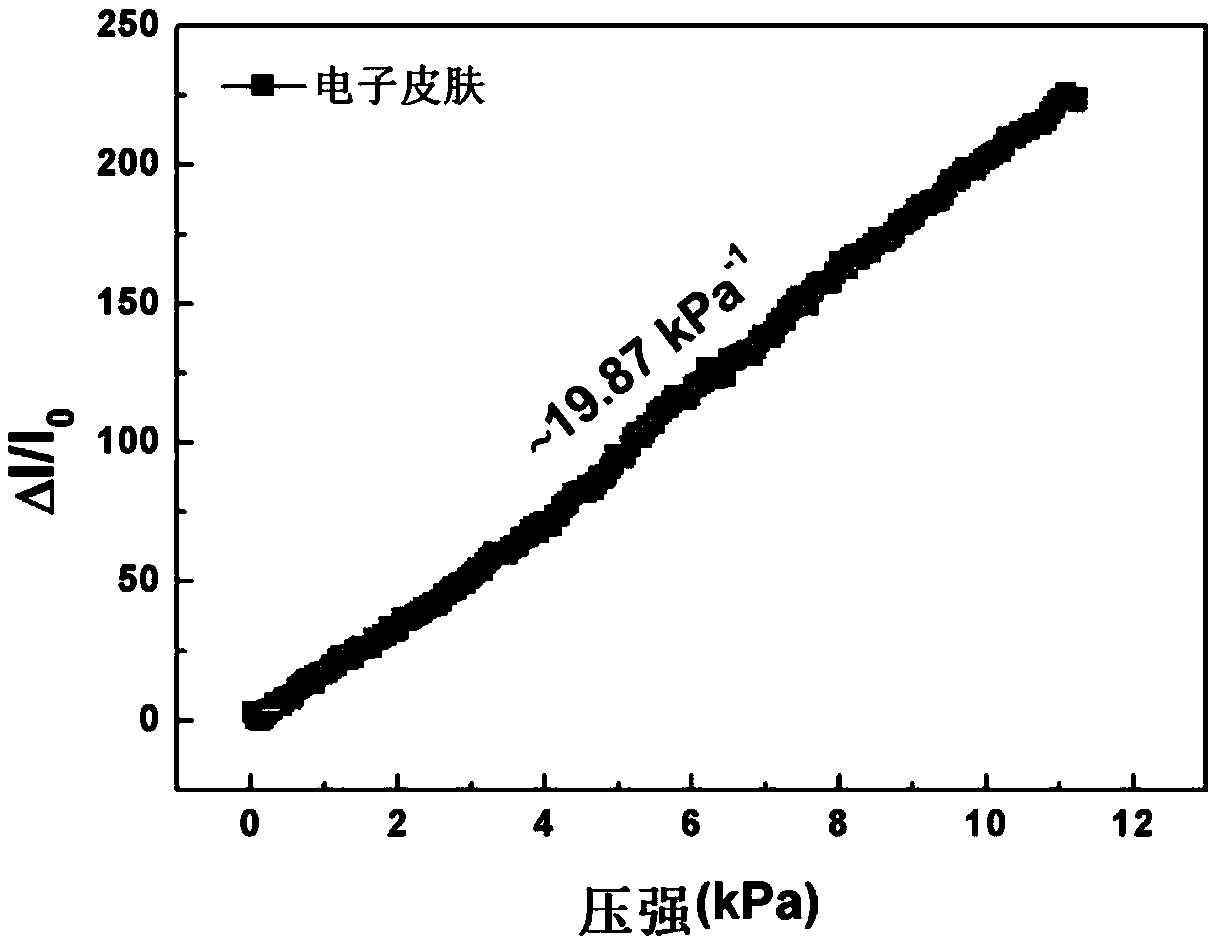

Examples

preparation example Construction

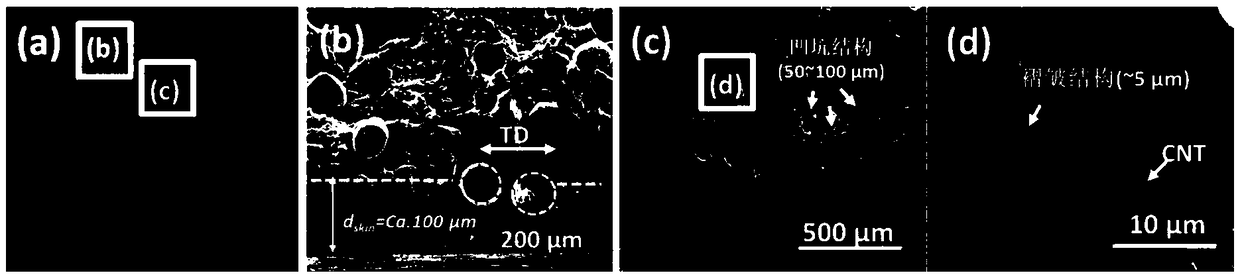

[0034] The preparation method of the electronic skin with pit microstructure of the present invention can be carried out in the following embodiments:

[0035] (1) First mix high-density polyethylene (HDPE) with silica microspheres (SiO 2 ) for melt blending to obtain HDPE / SiO 2 Blends; SiO 2 The mass fraction is 40-80wt.%;

[0036] (2) Melt-blending the elastomer and carbon nanotubes (CNT) to obtain the elastomer / CNT blend; the mass fraction of the CNT is 10 to 25wt.%; the steps (1) and (2) used The melt blending temperature is 180-200°C, the mixing speed is 80rpm, and the mixing time is 5-10min;

[0037] (3) Pulverize the blend raw materials prepared in step (1) and step (2) at room temperature to obtain HDPE / SiO with a particle size distribution of 80 to 500 mesh 2 The blend particles and the elastomer / CNT blend particles are dried;

[0038] (4) Use the elastomer / CNT blend particles prepared in step (3) as a single injection raw material for multi-melt multiple injecti...

Embodiment 1

[0044] The electronic skin is prepared by the following steps:

[0045] (1) Firstly high density polyethylene (high density polyethylene, HDPE, trade mark DGDA-6098, produced by China Qilu Petrochemical Company; weight average molecular weight 5.63×10 5 g / mol, number average molecular weight 6.75×10 4 g / mol, melt flow rate (MFR) is 0.09g / 10min (190℃ / 2.16kg, ASTM D1238), density 0.953g / cm 3 ) and silica microspheres (silica powder, SiO 2 , produced by Aladdin in China; real density 2.20g / cm 3 , with an average diameter of 85 μm) were blended in a torque rheometer, and the blending ratio was HDPE / SiO 2 =33.4 / 66.6wt.%, the blending temperature is preferably 200°C, the blending time is 8min, and the mixing speed is 80rpm.

[0046] (2) Next, ethylene-1-octene block copolymer (ethylene-α-octene block copolymer, OBC, trade mark infuse 9807, produced by U.S. DuPont; MFR=0.853g / 10min (190 ℃ / 2.16Kg, ASTMD1238 ), density 0.960g / cm 3 ) and carbon nanotubes (carbon nanotube, CNT, gra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com