Preparation method of blue light and near ultraviolet excitation type one-dimensional red nano fluorescent powder

A nano-fluorescent powder and near-ultraviolet technology, which is applied in chemical instruments and methods, luminescent materials, and the use of gas discharge lamps, etc., can solve problems such as poor safety performance, reduced quantum efficiency, and high equipment requirements, so as to ensure accurate control and enhance Luminous intensity, effect of increasing doping concentration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

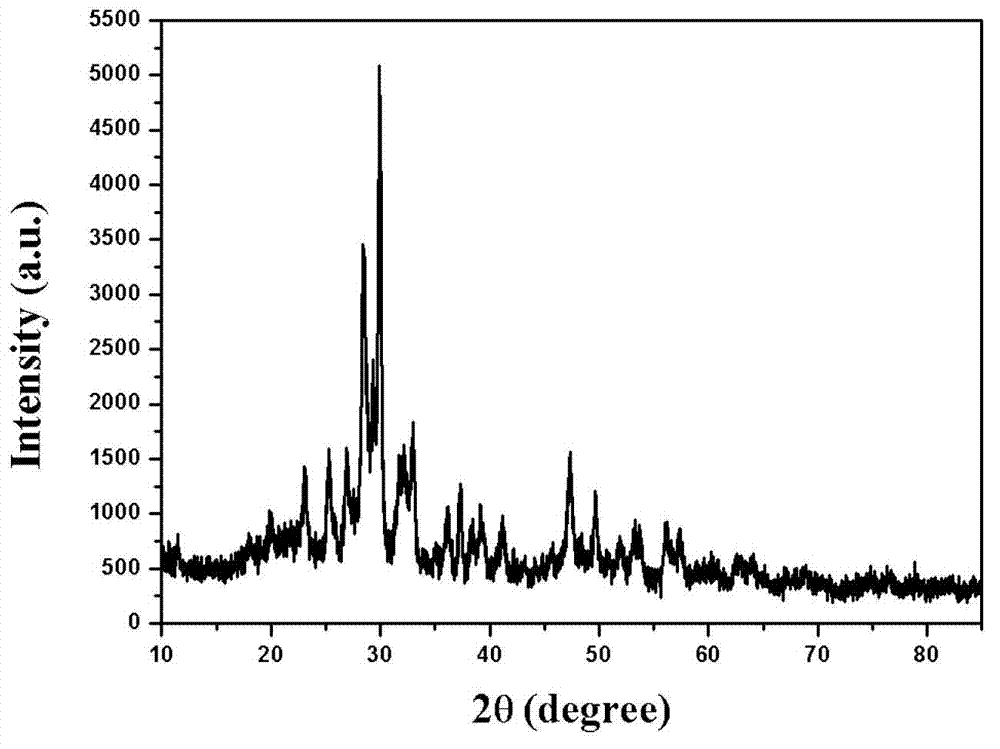

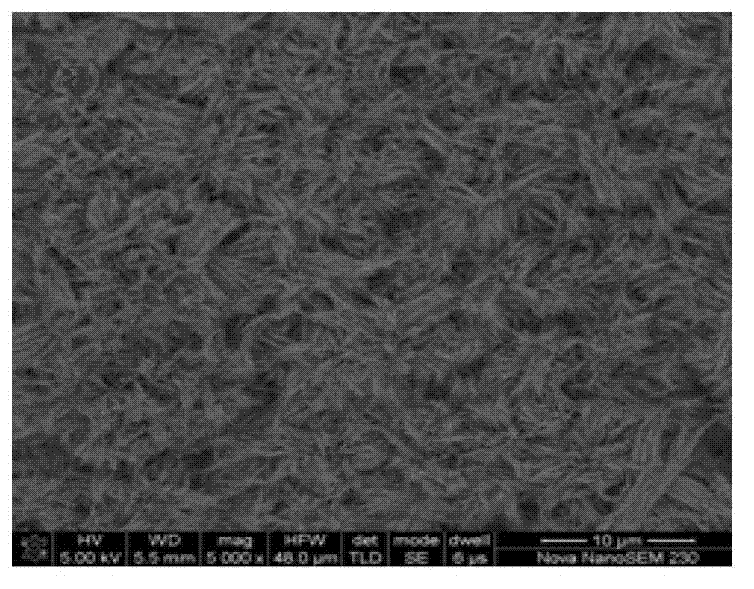

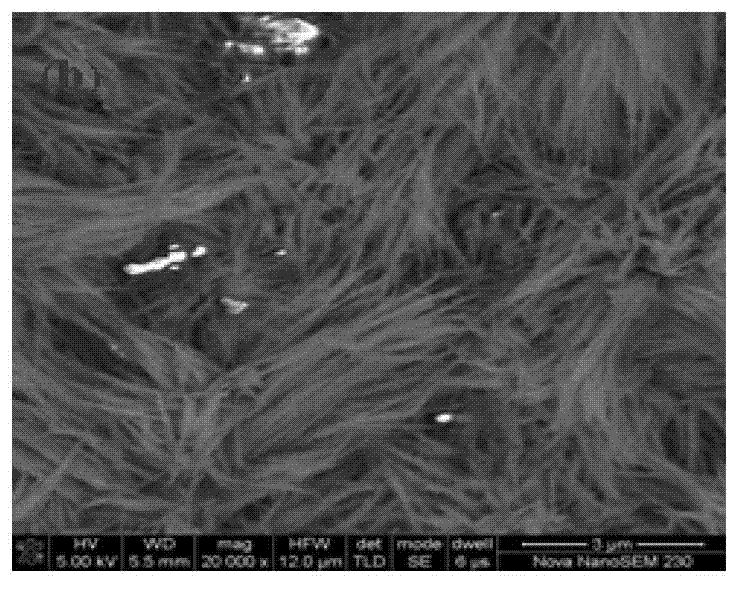

[0044] Embodiment 1. 1.046g GeO 2 , 0.4206g CaO, 0.2147g1 / 2 hydrated strontium acetate, 0.6012g tetrahydrated europium acetate mixed with 120ml deionized water, after ultrasonic treatment for 60min, moved into a 200ml polytetrafluoroethylene reactor, placed in a heating furnace, Insulate for 12 hours at 200°C. After the reaction was completed, it was naturally cooled to room temperature. Take it out and dry it in a drying oven at 60° C. to obtain a one-dimensional linear red nano phosphor powder with a diameter of about 5-60 nm and a length of 30-1000 microns.

Embodiment 2

[0045] Example 2. Mix 2.3ml TEOS, 0.4486g CaO, 0.2147g1 / 2 hydrated strontium acetate, 0.4009g tetrahydrated europium acetate, 46ml absolute ethanol and 124ml deionized water, and after ultrasonic treatment for 30min, move into 200ml polytetrafluoroethylene Put it in a vinyl fluoride reaction kettle, put it in a heating furnace, and keep it warm for 24 hours at a temperature of 200°C. After the reaction was completed, it was naturally cooled to room temperature. Take it out and dry it in a drying oven at 90° C. to obtain a one-dimensional linear red nano phosphor powder with a diameter of about 5-60 nm and a length of 30-1000 microns.

Embodiment 3

[0046] Embodiment 3. 1.046g GeO 2 , 2.3ml TEOS, 0.9534g CaO, 0.2147g1 / 2 hydrated strontium acetate, 0.8018g tetrahydrated europium acetate, 20ml absolute ethanol and 120ml deionized water were mixed, after ultrasonic treatment for 45min, they were transferred into a 200ml polytetrafluoroethylene reactor , placed in a heating furnace, and kept at a temperature of 200°C for 24 hours. After the reaction was completed, it was naturally cooled to room temperature. Take it out and dry it in a drying oven at 75°C to obtain a one-dimensional linear red nano phosphor powder with a diameter of about 5-60 nm and a length of 30-1000 microns.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com