Preparation method of polyimide/graphene composite material and product of material

A graphene composite and polyimide technology, which is applied in the field of preparation of conductive composite materials, can solve problems such as affecting transfer efficiency, poor polymer compatibility, and non-compliance with green chemistry.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

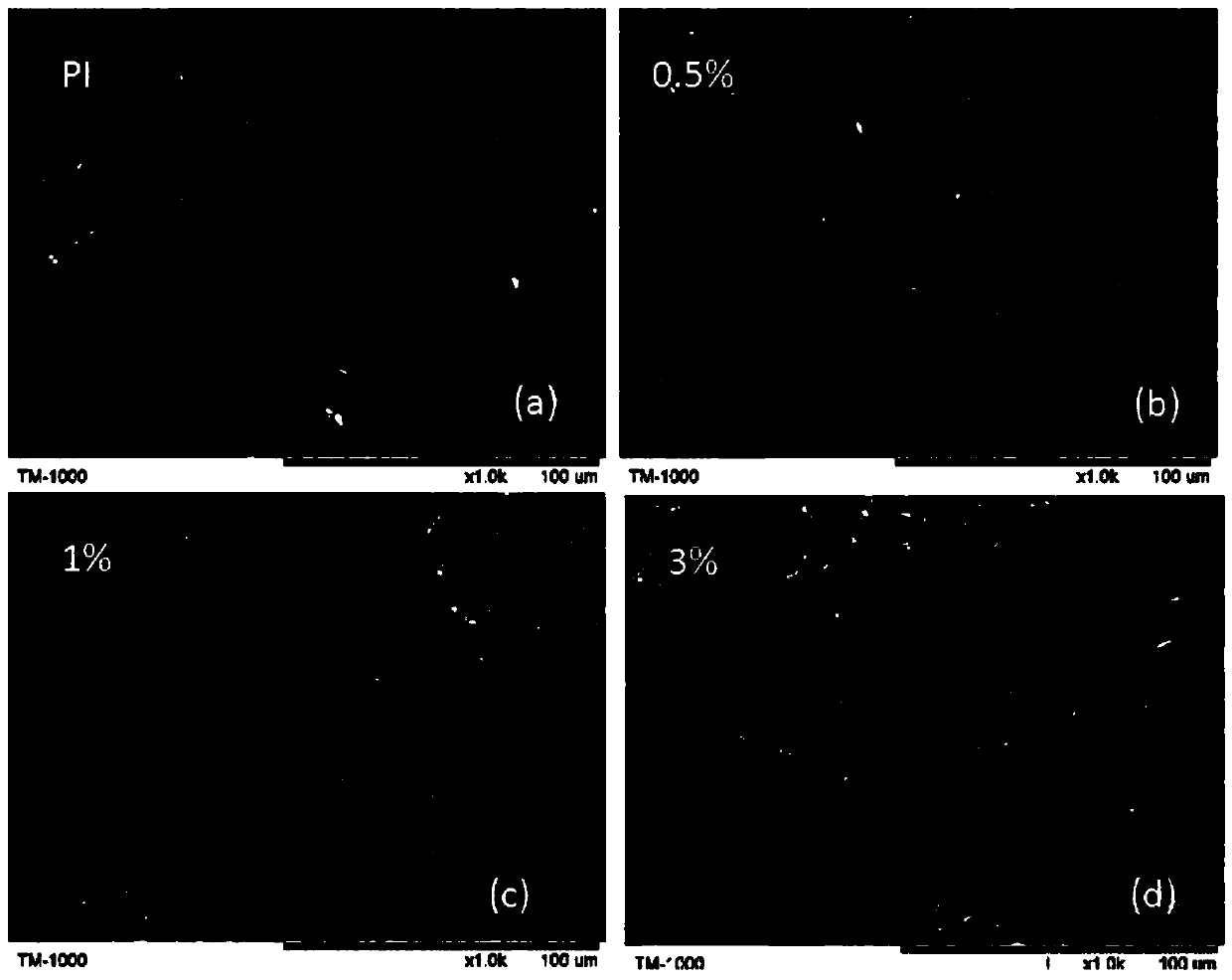

Image

Examples

Embodiment 1

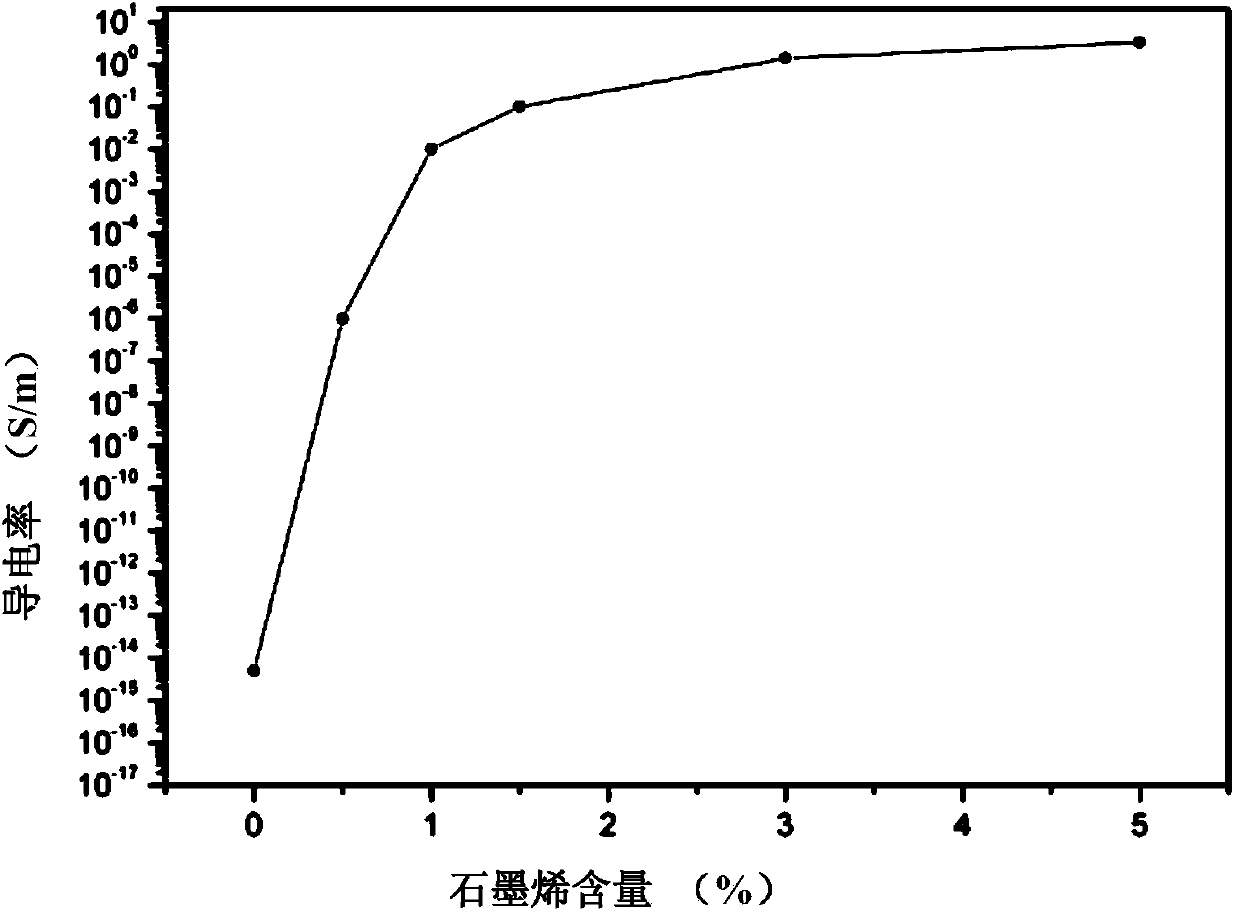

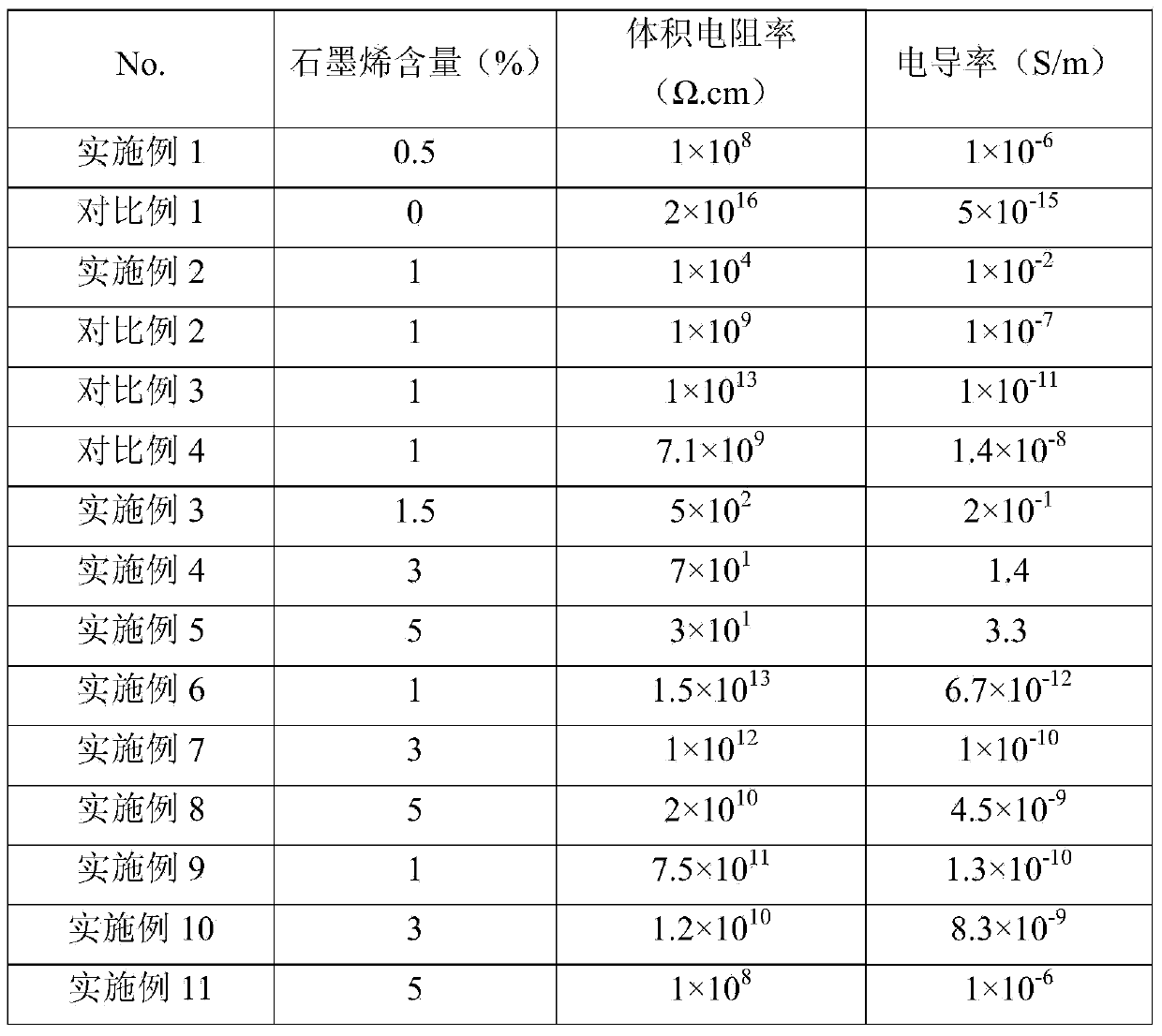

[0029] (1) Preparation of polyimide / graphene composite particles: dry Ultem1000P particles in a blast oven at 150°C for 4 hours, place 29.85g Ultem1000P particles and 0.15g graphene (0.5% graphene) in a high-speed mixer Stir to obtain polyimide / graphene composite particles; wherein the graphene is added into the high-speed mixer twice, each time stirring at a speed of 20000r / min for 30s at a high speed.

[0030] (2) High-temperature hot-press molding: preheat the polyimide / graphene composite particles prepared in step (1) at 240°C and 3MPa for 15min; then hot-press at 280°C and 10MPa for 30min; Cool naturally to 180°C for demoulding to prepare the target product. The performance test results of the obtained composite materials are shown in Table 1.

Embodiment 2

[0034] Others are the same as in Example 1, the added Ultem1000P particles are 29.7g, the graphene content is 0.3g (1% graphene), and the number of high-speed stirring is 3 times. The performance test results of the obtained composite materials are shown in Table 1.

Embodiment 3

[0044] Others are the same as in Example 1, the added Ultem1000P particles are 29.55g, the graphene content is 0.45g (1.5% graphene), and the number of high-speed stirring is 6 times. The performance test results of the obtained composite materials are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com