Preparation method and application of graphene oxide-protamine/sodium alginate compound

A technology of protamine and sodium alginate, which is applied in the fields of material synthesis and biomedicine, can solve the problems of stacking of lamellae and affect biological applications, and achieves the effects of uniform particle size distribution, easy mass production and broad application prospects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

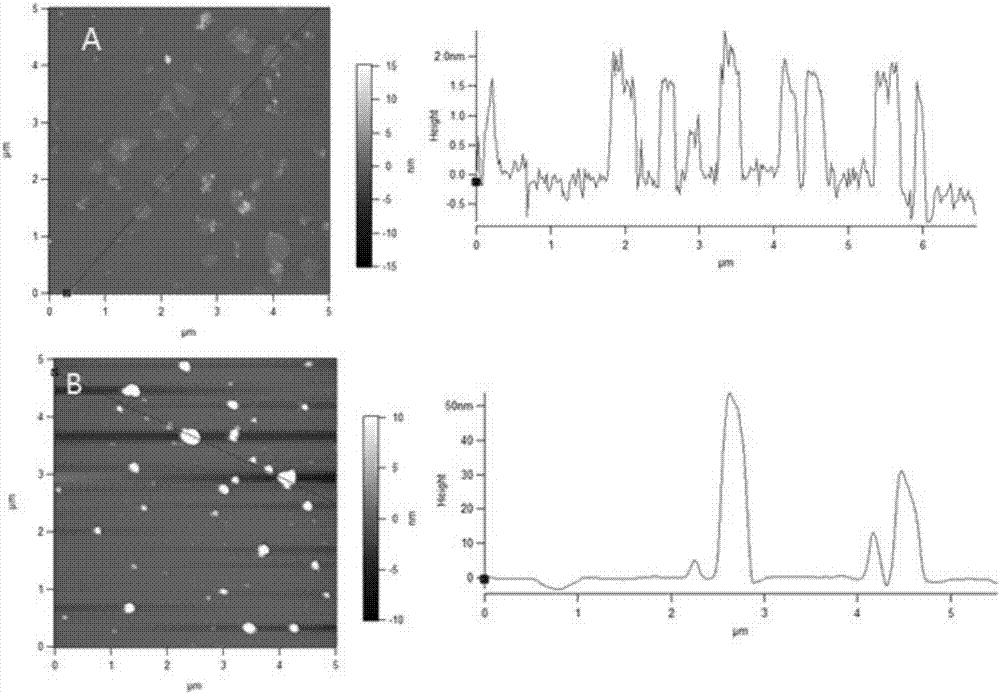

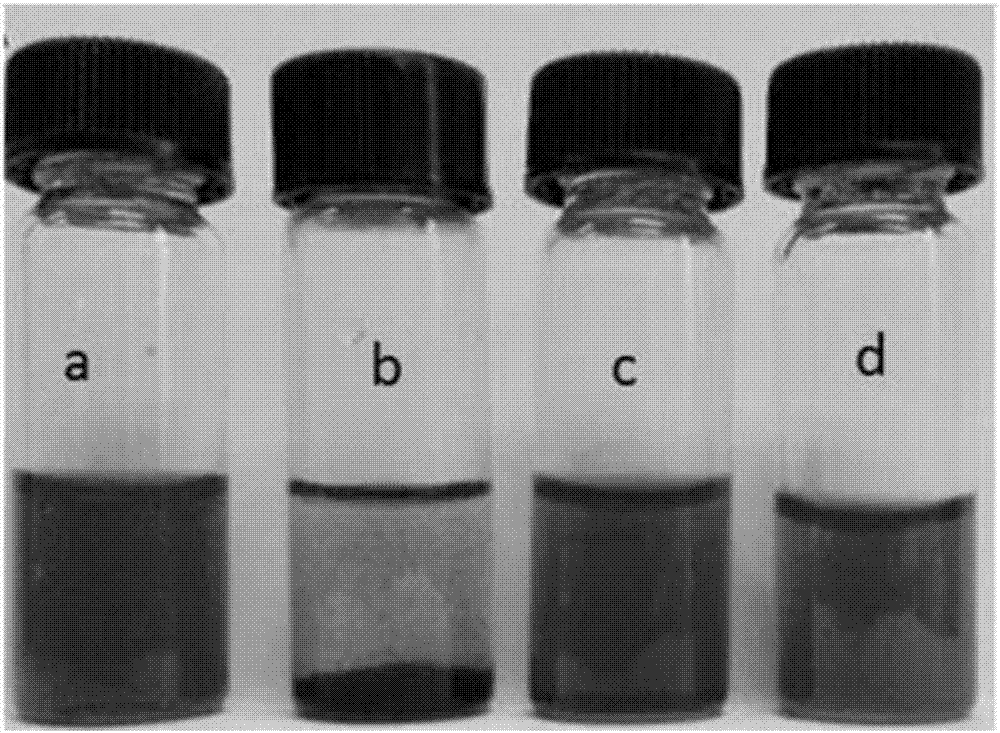

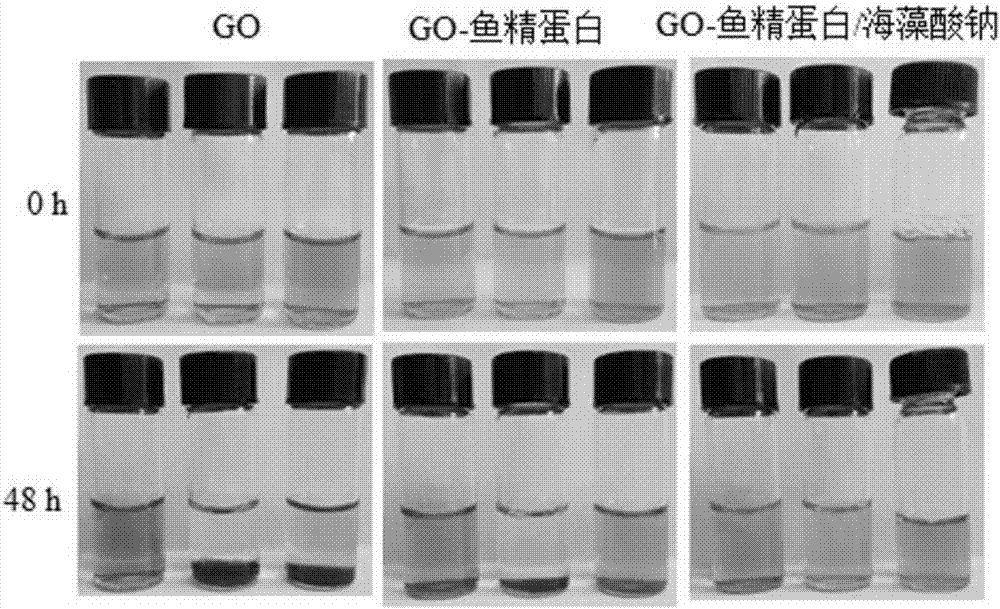

[0028] (1) Break the graphene oxide aqueous dispersion into small-sized graphene oxide aqueous dispersions with a cell disruptor, power 400w, ultrasonic time for half an hour, and conduct in an ice-water bath; (2) Dissolve protamine sulfate in deionized water , to prepare a 1 mg / ml solution; (3) Under magnetic stirring, slowly add 1 mg / ml GO aqueous dispersion to the solution and stir for 30 minutes. The mass ratio of GO to protamine sulfate was 1:4. Then the mixture was filtered and washed three times with a microporous membrane, and dispersed in pure water to obtain a GO-protamine aqueous dispersion; (4) Sodium alginate was dissolved in deionized water to prepare a 1 mg / ml solution; (5 ) Under magnetic stirring, slowly add GO-protamine aqueous dispersion to sodium alginate solution and stir for 30 minutes. The mass ratio of protamine sulfate to sodium alginate is 1:1. Then the mixture was suction-filtered and washed three times with a 0.22 μm microporous membrane, and disp...

Embodiment 2

[0031] (1) The graphene oxide aqueous dispersion is broken into small-sized graphene oxide aqueous dispersions with a cell breaker, the power is 250w, the ultrasonic time is 2 hours, and the ice water bath is used; (2) Protamine sulfate is dissolved in deionized water , to make a 0.2 mg / ml solution; (3) Under magnetic stirring, slowly add 0.2 mg / ml GO aqueous dispersion to the solution and stir for 30 minutes. The mass ratio of GO to protamine sulfate was 1:10. Then the mixture was filtered and washed three times with a microporous membrane, and dispersed in pure water to obtain a GO-protamine aqueous dispersion; (4) Sodium alginate was dissolved in deionized water to make a 0.2 mg / ml solution; ( 5) Under magnetic stirring, slowly add GO-protamine aqueous dispersion to sodium alginate solution and stir for 30 minutes. The mass ratio of protamine sulfate to sodium alginate is 1:1. Then the mixture was suction-filtered and washed three times with a 0.22 μm microporous membrane...

Embodiment 3

[0034] (1) Use a cell breaker to crush the graphene oxide aqueous dispersion into small-sized graphene oxide aqueous dispersions with a power of 300w and ultrasonic time of 1 hour in an ice-water bath; (2) Dissolve protamine sulfate in deionized water , to make a 0.5 mg / ml solution; (3) Under magnetic stirring, slowly add 0.5 mg / ml GO aqueous dispersion to the solution and stir for 30 minutes. The mass ratio of GO to protamine sulfate was 1:1. Then the mixture was filtered and washed three times with a microporous membrane, and dispersed in pure water to obtain a GO-protamine aqueous dispersion; (4) Sodium alginate was dissolved in deionized water to prepare a 0.5 mg / ml solution; (5 ) Under magnetic stirring, slowly add GO-protamine aqueous dispersion to sodium alginate solution and stir for 30 minutes. The mass ratio of protamine sulfate to sodium alginate is 1:1. Then the mixture was suction-filtered and washed three times with a 0.22 μm microporous membrane, and dispersed...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com