Preparation of nitrobenzene derivative hydrogenation reaction catalyst, catalyst and application of catalyst

A technology of nitrobenzene derivatives and hydrogenation reaction, which is applied in the field of preparation of non-precious metal catalysts, can solve the problems of difficult application and low activity of iron-nitrogen-carbon three-way catalysts, achieve high-temperature treatment time is short, the synthesis method is simple, good chemoselectivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

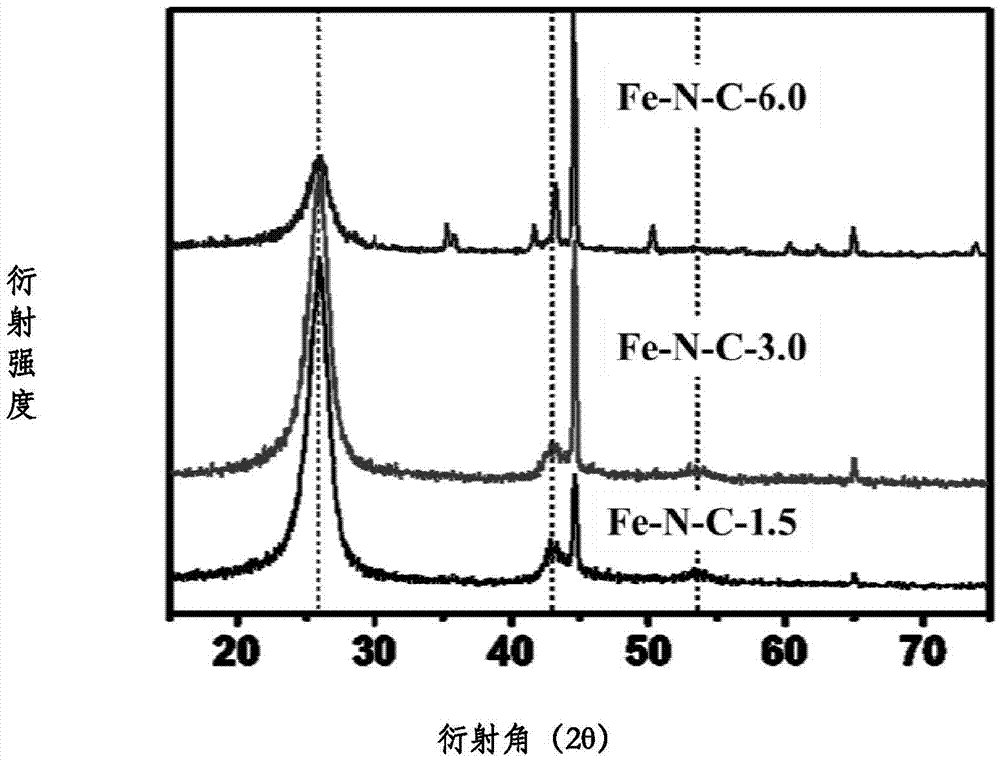

[0019] A catalyst with a mass fraction of iron of 1.5% was prepared. Weigh 0.043 g of ferric chloride solid, add 0.1593 g of o-phenanthroline, and then add 50 ml of ethanol, stir to completely dissolve the iron salt and o-phenanthroline, and obtain a clear wine red solution. The solution was refluxed at 60°C for 12 hours to completely coordinate the iron salt and o-phenanthroline. Weighing 0.7973 g of the material was added to the above solution, and the ultrasonic wave was continued for 4 hours to completely disperse the carbon nanotubes, and then the solvent was removed by rotary evaporation to obtain a catalyst precursor. The precursor was pyrolyzed at 800 degrees Celsius for 120 minutes in a nitrogen atmosphere, and the black powder was obtained after the furnace temperature dropped to room temperature, which was the catalyst.

Embodiment 2

[0021] A catalyst with a mass fraction of iron of 3.0% was prepared. Preparation method Referring to Example 1, the solid quality of ferric chloride was changed to 0.0871 grams, and the quality of o-phenanthroline was changed to 0.3186 grams.

Embodiment 3

[0023] A catalyst with a mass fraction of iron of 6.0% was prepared. Preparation method Referring to Example 1, the solid quality of ferric chloride was changed to 0.1783 grams, and the quality of o-phenanthroline was changed to 0.637 grams.

[0024] Table 1 is the reaction result of different substrates

[0025]

[0026]

[0027] Reaction condition: 0.5mmol substrate, with respect to the embodiment 1 catalyst of substrate 4.5mol%Fe, 4 milliliters of solvents (2ml H 2 O+2ml THF), 130°C, 5Mpa H 2 , a 110℃, 5MpaH 2 .

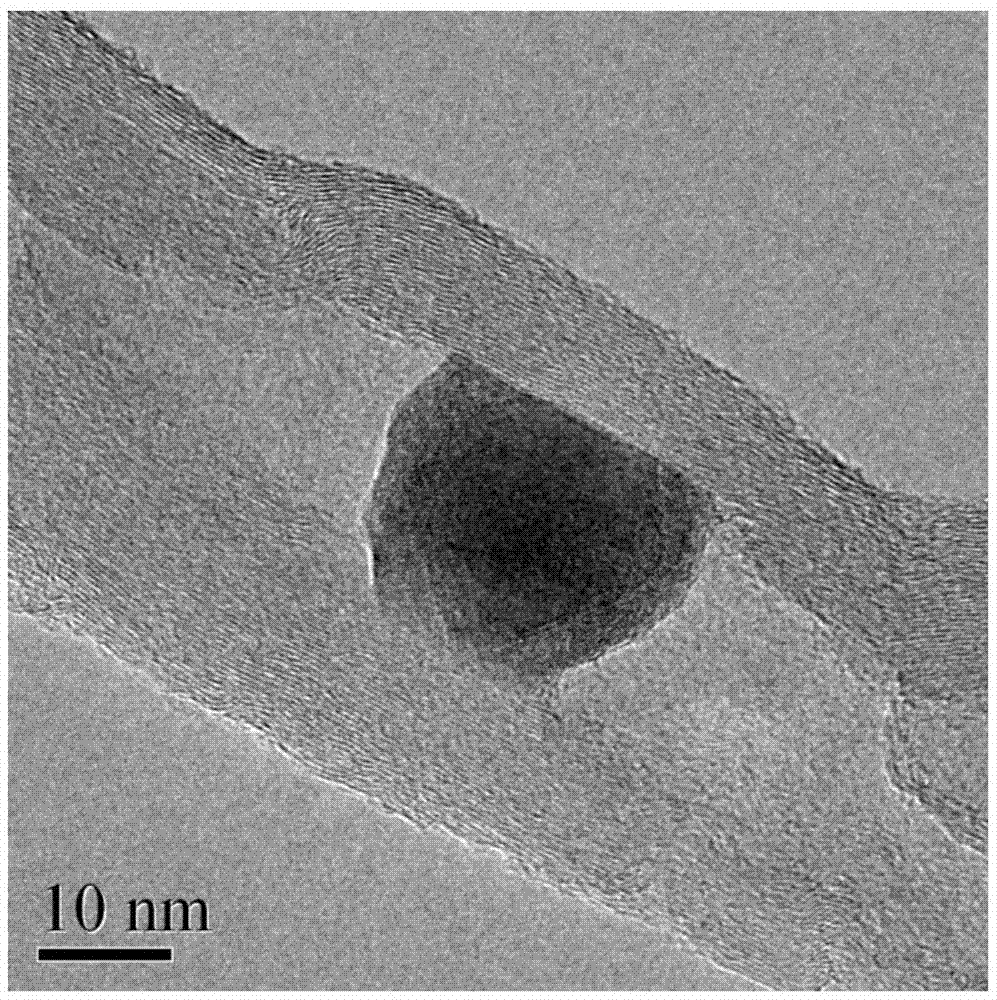

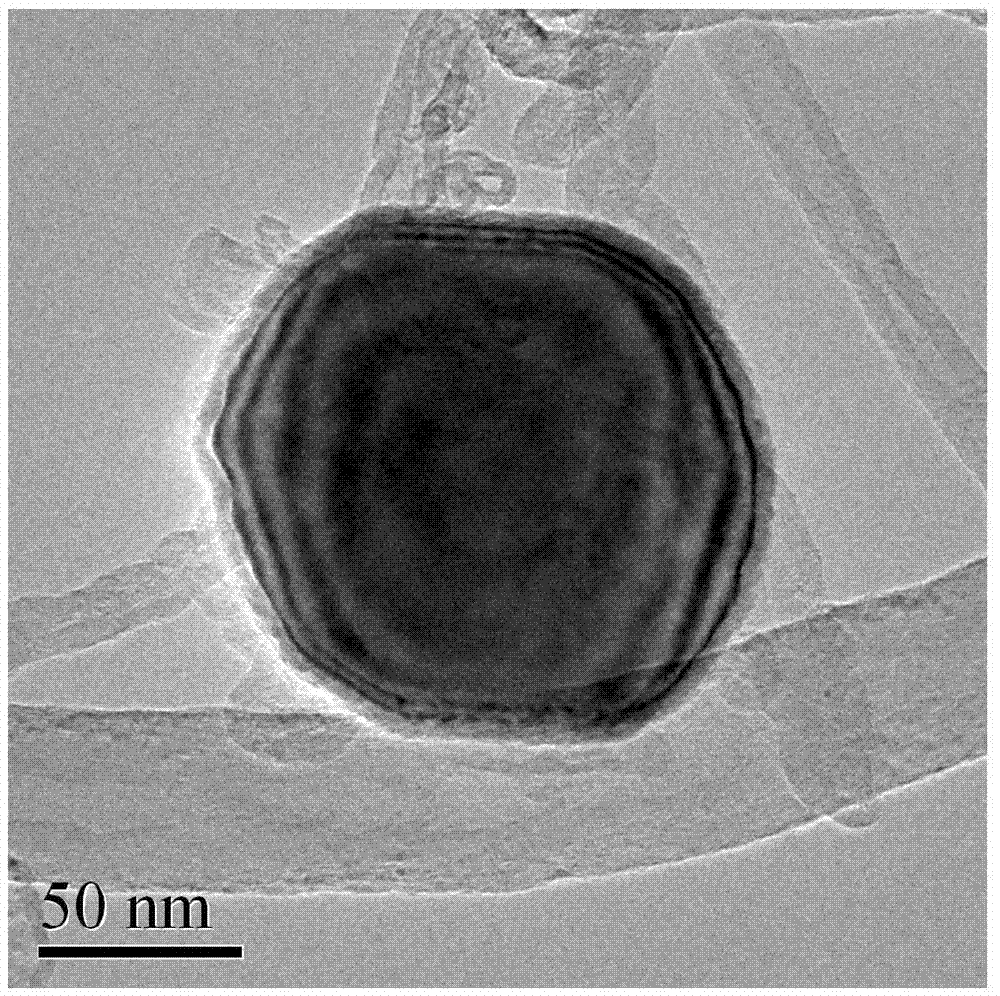

[0028] The invention relates to a method for preparing a catalyst for hydrogenation of nitrobenzene derivatives by using carbon nanotubes as carriers to support iron-nitrogen-carbon active components. Specifically, the iron-nitrogen precursor is obtained by the coordination of o-phenanthroline and iron salt; part of the precursor is introduced into the interior of carbon nanotubes by ultrasound; finally, the iron-nitrogen precursor is converted into iro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com