Lithium titanate coated positive electrode material for power battery and preparation method

A technology of lithium titanate coating and positive electrode materials, which is applied in battery electrodes, secondary batteries, circuits, etc., can solve the problems of unsolvable batteries, complex procedures, flatulence, etc., achieve simple process, broad application prospects, and suppress flatulence Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

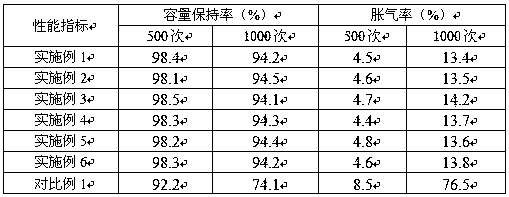

Examples

Embodiment 1

[0029] Nickel sulfate, cobalt sulfate, manganese sulfate are prepared according to the mixture of mol ratio 0.53:0.12:0.12, be formulated with the mixed solution that molar concentration is 1.3mol / L, then add mass concentration in 66g mixed solution and be 13% sodium hydroxide solution, Adjust the pH value to 10.5, heat and stir the reaction, the temperature of the heating and stirring reaction is 100°C, the stirring speed is 250r / min, and the stirring time is 2h to prepare the positive electrode active material precursor solution; then add 13g to the 76g precursor solution Graphene oxide, 11g chitosan, stirring reaction, separation, obtained the positive electrode material precursor of hydrogel coating; Then the positive electrode material precursor of 33g hydrogel coating, 13g butyl titanate are added 51g anhydrous In ethanol, then slowly add 3g of acetylacetone dropwise, let it stand and age for 24.5h, and then evaporate to dryness of absolute ethanol to obtain the precursor...

Embodiment 2

[0034]Nickel sulfate, cobalt sulfate, manganese sulfate are formulated according to the mixture of mol ratio 0.53:0.12:0.12, are mixed with the mixed solution that molar concentration is 1.2mol / L, then add mass concentration in 62g mixed solution and be 12% sodium hydroxide solution, Adjust the pH value to 10, heat and stir the reaction, the temperature of the heating and stirring reaction is 110°C, the stirring speed is 220r / min, and the stirring time is 3h to prepare the positive electrode active material precursor solution; then add 12g to the 79g precursor solution Graphene oxide, 9g chitosan, stirring reaction, separation, obtained the positive electrode material precursor of hydrogel coating; Then the positive electrode material precursor of 32g hydrogel coating, 11g butyl titanate are added 54g anhydrous In ethanol, then slowly add 3g of acetylacetone dropwise, let it stand and age for 24.5h, and then evaporate to dryness of absolute ethanol to obtain a modified positive...

Embodiment 3

[0037] Nickel sulfate, cobalt sulfate, manganese sulfate are formulated according to the mixture of mol ratio 0.54:0.14:0.14, are mixed with the mixed solution that molar concentration is 1.4mol / L, then add mass concentration in 67g mixed solution and be 14% sodium hydroxide solution, Adjust the pH value to 11, heat and stir the reaction, the temperature of the heating and stirring reaction is 100°C, the stirring speed is 260r / min, and the stirring time is 2h to prepare the positive active material precursor solution; then add 14g to the 72g precursor solution Graphene oxide, 14g chitosan, stirring reaction, separation, obtained the positive electrode material precursor of hydrogel coating; Then the positive electrode material precursor of 34g hydrogel coating, 13g butyl titanate are added 49g anhydrous In ethanol, then slowly add 4g of acetylacetone dropwise, let it stand and age for 25.5h, and then evaporate to dryness of absolute ethanol to obtain the precursor of the modifi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com