Anticorrosive and flame-retardant epoxy resin coating and preparation method thereof

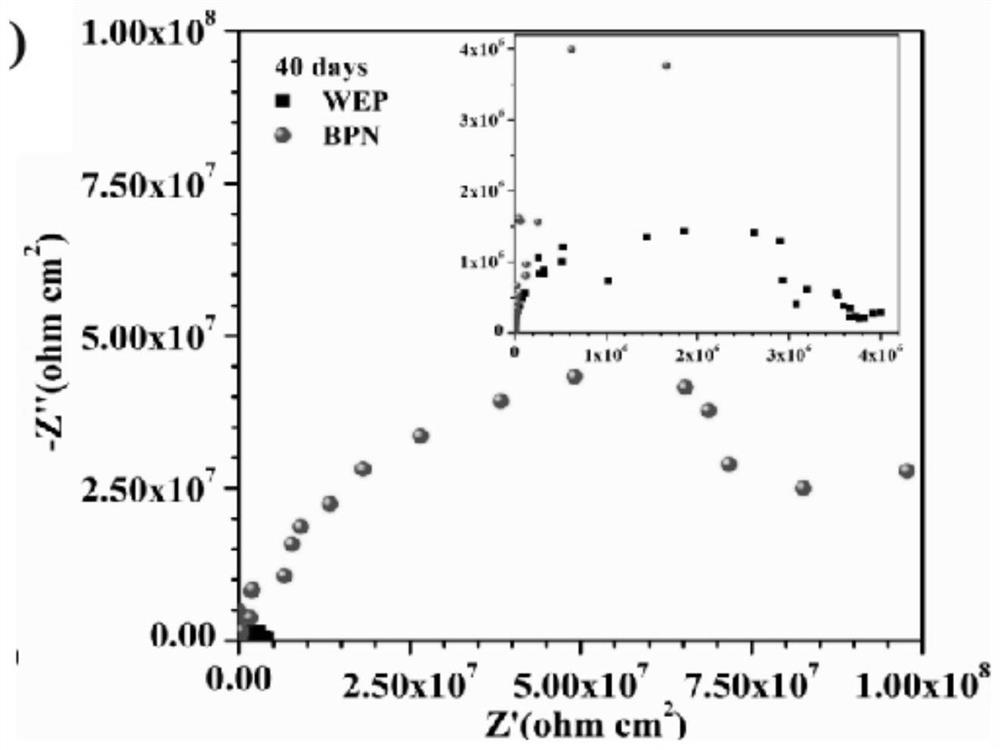

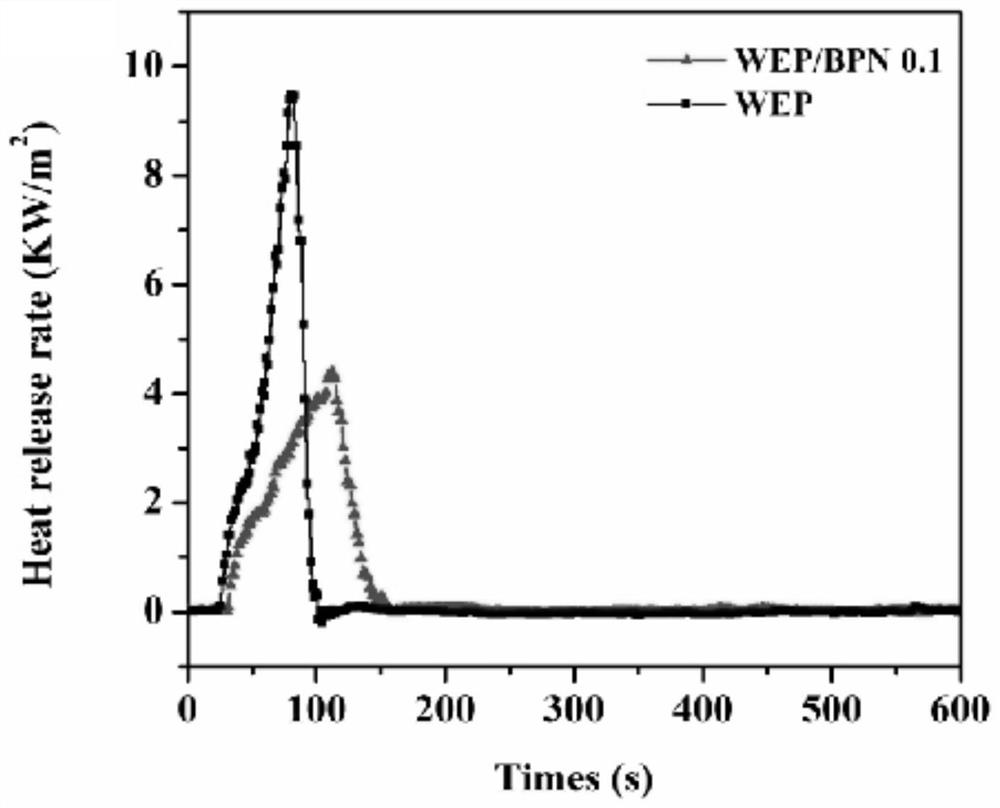

An epoxy resin and flame retardant coating technology, applied in the field of coatings, can solve the problems of difficulty in preventing the infiltration of water, oxygen and corrosive ions, large macromolecular chain gaps, poor anti-corrosion performance, etc., and achieves easy large-scale industrial production, high Effects of adhesion properties, excellent anti-corrosion and flame retardant properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] An epoxy resin anticorrosion and flame-retardant coating, which comprises epoxy resin, crosslinking agent, aminated black phosphorus, water, and the specific component formula is as follows:

[0030]

[0031] The preparation method of above-mentioned epoxy resin anticorrosion flame retardant coating, its steps are as follows:

[0032] a. Preparation of black phosphorus amidation: at room temperature, put black phosphorus crystal powder and urea in a molar ratio of 1:1 in a dry and clean ball-sealed grinding tank, add agate or ceramic balls of appropriate size and quality, and use a ball mill After ball milling for 10 hours, disperse it in deoxygenated deionized water, centrifuge at 3000rpm for 20 minutes, and take the upper dispersion;

[0033] b. Preparation of anti-corrosion and flame-retardant coatings: Weigh epoxy emulsion and deionized water by mass percentage under room temperature conditions, and disperse evenly with ultrasonic stirring to obtain epoxy dispers...

Embodiment 2

[0035] An epoxy resin anti-corrosion and flame-retardant coating, its components include epoxy resin, crosslinking agent, aminated black phosphorus, acetone, and its specific component formula is as follows:

[0036]

[0037] The preparation method of above-mentioned epoxy resin anticorrosion flame retardant coating, its steps are as follows:

[0038] a. Preparation of black phosphorus amidation: at room temperature, put black phosphorus crystal powder and urea in a molar ratio of 1:4 in a dry and clean ball-sealed grinding pot, add agate or ceramic balls of appropriate size and quality, and use a ball mill After ball milling for 8 hours, it was dispersed in deoxygenated deionized water, centrifuged at 3000 rpm for 30 minutes, and the upper dispersion liquid was taken; vacuum-dried to obtain aminated black phosphorus powder.

[0039] b. Preparation of anti-corrosion and flame-retardant coatings: Weigh epoxy resin and acetone by mass percentage under room temperature, and di...

Embodiment 3

[0041] An epoxy resin anti-corrosion and flame-retardant coating, its components include epoxy resin, crosslinking agent, black phosphorous amidation, isopropanol / ethylene glycol diglycidyl ether (2:1), and its specific component formula is as follows :

[0042]

[0043]

[0044] The preparation method of above-mentioned epoxy resin anticorrosion flame retardant coating, its steps are as follows:

[0045] a. Preparation of black phosphorus amidation: at room temperature, put black phosphorus crystal powder and urea in a molar ratio of 1:4 in a dry and clean ball-sealed grinding pot, add agate or ceramic balls of appropriate size and quality, and use a ball mill After ball milling for 6 hours, it was dispersed in deoxygenated deionized water, centrifuged at 3000 rpm for 20 minutes, and the upper dispersion liquid was taken; freeze-dried to obtain aminated black phosphorus powder.

[0046] b. Preparation of anti-corrosion and flame-retardant coating: Weigh epoxy resin and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com