Method for emulsifying oil product through membrane

A membrane emulsification and oil product technology, applied in the field of membrane emulsification, can solve the problems of difficult control of emulsion particle size and low flux of membrane emulsification technology, and achieve good chemical stability and thermal stability, good anti-pollution performance, high The effect of emulsifying flux

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

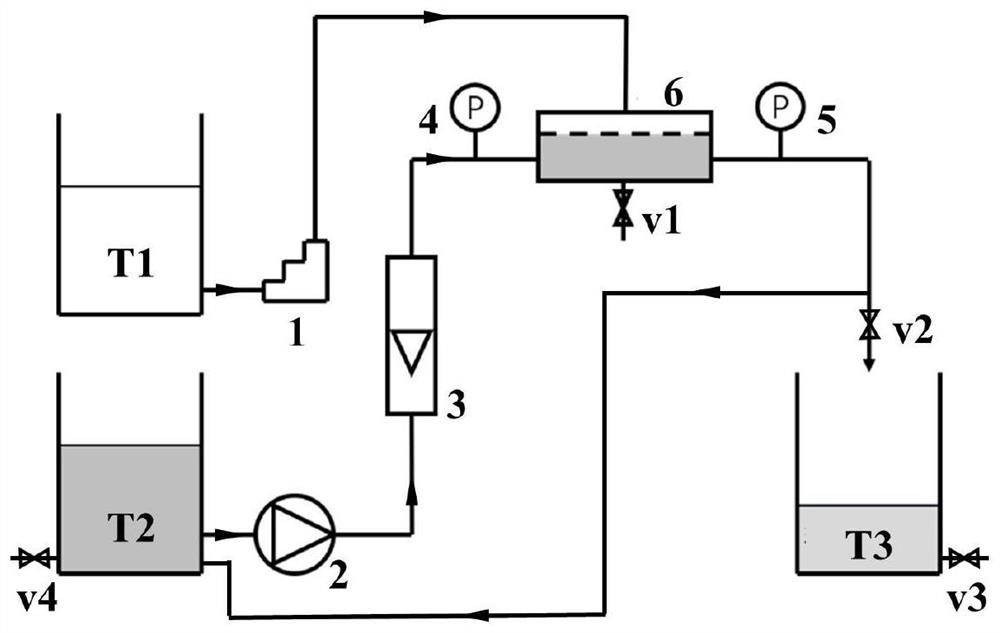

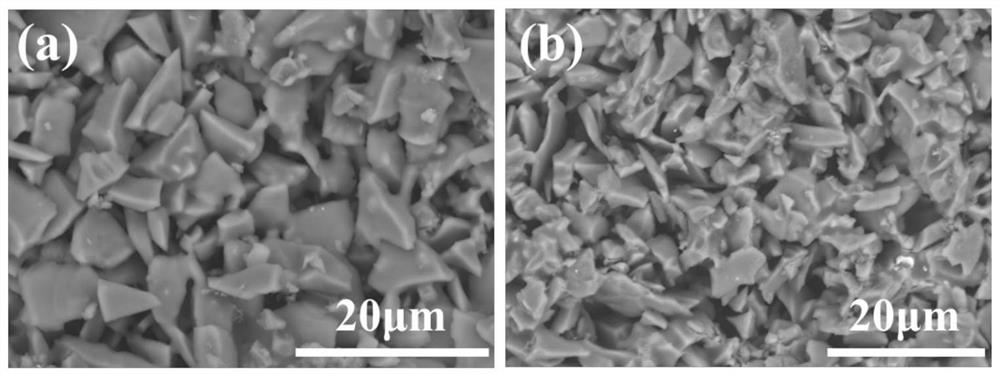

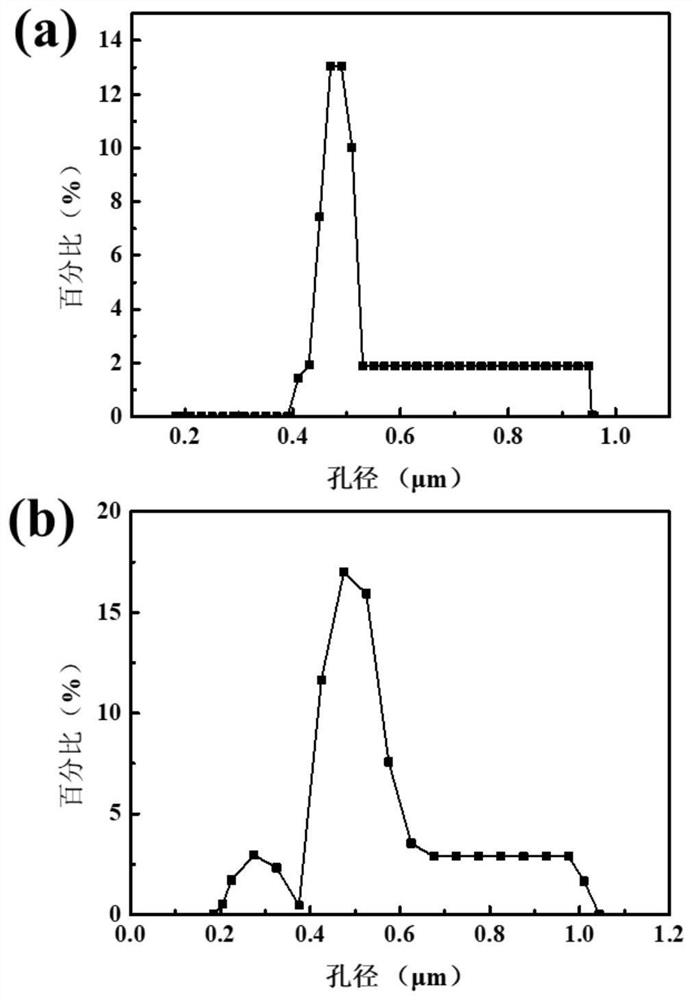

[0033] The raw material components for preparing the emulsion include lubricating oil and deionized water. Preheat the lubricating oil to 50°C and prepare 40mL of hexadecyltrimethoxysilane with a concentration of 0.05mol / L by using a sheet-type silicon carbide ceramic membrane with an average pore size of 500nm and a porosity of 48% as a modified carrier The (HDTMS) / ethanol solution was stirred at 35° C. for 2 h and set aside. Soak the silicon carbide ceramic membrane in 0.05 mol / L HDTMS / ethanol solution for 12 hours. After taking it out, clean the surface of the membrane with absolute ethanol and dry it in an oven at 120°C for later use. figure 2 It is the SEM picture of the silicon carbide ceramic membrane prepared in the laboratory. It can be seen that the microstructure of the membrane has not changed significantly before and after hydrophobic modification. image 3 (a) is the pore size distribution diagram of the hydrophilic silicon carbide ceramic membrane, image 3 (...

Embodiment 2

[0037] A sheet-type silicon carbide ceramic membrane with an average pore diameter of 500 nm and a porosity of 30% was used as a modified carrier, and 20 mL of HDTMS / ethanol solution with a concentration of 0.03 mol / L was prepared and stirred at 35°C for 2 h for later use. Spray 5mL of 0.03mol / L HDTMS / ethanol solution evenly on the surface of the silicon carbide film, the spray rate is 0.1mL / s, and the spray volume is 1.5mL / cm 2 , put it in an oven at 120°C and dry it for later use. The water contact angle on the surface of the modified film is 135°. The raw material components for preparing the emulsion include lubricating oil and deionized water. Preheat the lubricating oil to 50°C for later use. A constant flow pump is used to transport the dispersed phase at a constant flow rate, but it is not limited to this. A peristaltic pump is used to provide the membrane surface shear force formed by the continuous phase flow, and the membrane surface velocity is controlled to be 0....

Embodiment 3

[0039] A sheet-type silicon carbide ceramic membrane with an average pore diameter of 500 nm and a porosity of 26% was used as a modified carrier, and 40 mL of HDTMS / ethanol solution with a concentration of 0.05 mol / L was prepared and stirred at 35°C for 2 h for later use. Soak the silicon carbide ceramic membrane in 0.05mol / L HDTMS / ethanol solution for 12 hours, wash the surface of the membrane with absolute ethanol after taking it out, and dry it in an oven at 120°C for later use. The water contact angle of the modified membrane surface is 140 °. The raw material components for preparing the emulsion include lubricating oil and deionized water. Preheat the lubricating oil to 50°C for later use. A constant flow pump is used to transport the dispersed phase at a constant flow rate, but it is not limited to this. A peristaltic pump is used to provide the membrane surface shear force formed by the continuous phase flow, and the membrane surface velocity is controlled to be 0.68...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com