Preparation method of modified graphite cathode material of lithium-ion power battery

A graphite negative electrode and power battery technology, applied in battery electrodes, circuits, electrical components, etc., can solve problems such as poor practicability and complicated process, achieve low production cost, simple process flow, and improve cycle performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

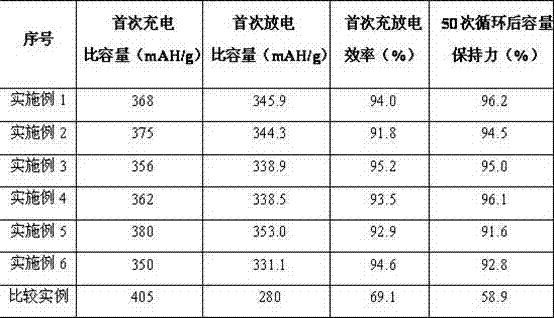

Examples

Embodiment 1

[0019] (1) Under constant stirring, dissolve 2g of sucrose in 100ml of deionized water to make it a diluted solution;

[0020] (2) Slowly add 20g of natural graphite to the above solution, control the temperature at 85°C, and stir vigorously until the deionized water is evaporated to dryness;

[0021] (3) Vacuum-dry the mixture obtained in step (2) at 100°C for 24 hours;

[0022] (4) Put the dried mixture in step (3) into a porcelain ark, compact it slightly, and place it in an inert gas N 2 Or under the protection of Ar, the temperature was raised to 700°C at 5°C / min, kept for 3h, and then naturally cooled to room temperature, and the obtained product was pulverized to obtain the modified graphite negative electrode material.

Embodiment 2

[0024] (1) Under constant stirring, dissolve 3g of glucose in 150ml of deionized water to make it into a diluted solution;

[0025] (2) Slowly add 30g of natural graphite into the above solution, control the temperature at 95°C, and stir vigorously until the deionized water is evaporated to dryness;

[0026] (3) Vacuum-dry the mixture obtained in step (2) at 110°C for 18 hours;

[0027] (4) Put the dried mixture in step (3) into a porcelain ark, compact it slightly, and place it in an inert gas N 2 Or under the protection of Ar, the temperature was raised to 800°C at 6°C / min, kept for 5h, and then naturally cooled to room temperature, and the obtained product was pulverized to obtain a modified graphite negative electrode material.

Embodiment 3

[0029] (1) Under constant stirring, dissolve 4g of soluble starch in 200ml of deionized water to make it a diluted solution;

[0030] (2) Slowly add 40g of natural graphite into the above solution, control the temperature at 90°C, and stir vigorously until the deionized water is evaporated to dryness;

[0031] (3) Vacuum-dry the mixture obtained in step (2) at 120°C for 20 hours;

[0032] (4) Put the dried mixture in step (3) into a porcelain ark, compact it slightly, and place it in an inert gas N 2 Or under the protection of Ar, the temperature was raised to 900°C at 8°C / min, kept for 2h, and then naturally cooled to room temperature, and the obtained product was pulverized to obtain a modified graphite negative electrode material.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com