Elastomer film with multistage microstructure, preparation method of elastomer film and flexible pressure sensor comprising elastomer film

A technology of pressure sensors and elastomers, applied in the direction of instruments, measuring force, measuring devices, etc., can solve problems such as difficult mass production, complex preparation process, narrow sensing range, etc., achieve stable response, great application potential, and high sensitivity high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

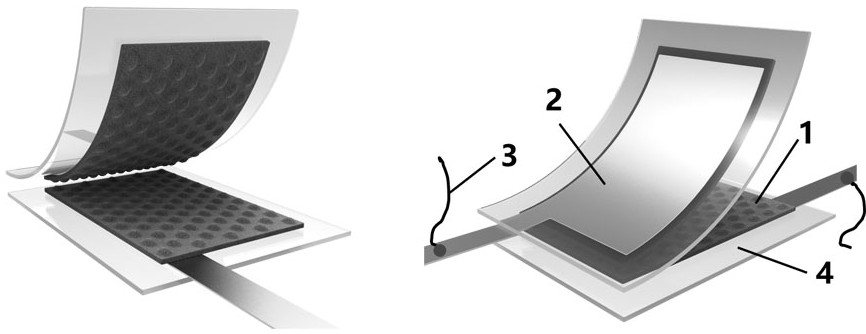

[0037] A preparation method of an elastomer film with a multi-level microstructure is prepared by the following steps:

[0038] Step 1, processing and customizing the collection template of electrospinning;

[0039] Step 2. Change the receiving device in the electrospinning equipment from a drum to a collection template, and adjust the parameters of the electrospinning equipment;

[0040] Electrospinning is a special fiber manufacturing process. The polymer solution or melt is jet-spun in a strong electric field. Under the action of the electric field, the droplet at the needle changes from a spherical shape to a conical shape (ie "Taylor cone") , and extend from the conical tip to obtain fiber filaments. In this way, polymer filaments with nanoscale diameters can be produced.

[0041] Step 3, preparing a thermoplastic polyurethane (TPU) elastomer solution to obtain an electrospinning solution;

[0042] Step 4, extracting the electrospinning liquid, and spinning through the...

Embodiment 1

[0058] A kind of preparation method of elastomer film is made by following steps:

[0059] Step 1, processing and customizing the collection template of electrospinning;

[0060] Step 2. Change the receiving device in the electrospinning equipment from a drum to a collection template, and adjust the parameters of the electrospinning equipment;

[0061] Step 3, preparing a thermoplastic polyurethane (TPU) elastomer solution to obtain an electrospinning solution;

[0062] Step 4: extracting the electrospinning solution and spinning it through the electrospinning equipment; after the spinning is completed, the film is peeled off from the collection template to obtain an elastomeric film with no protrusions on the surface and randomly distributed fiber grids inside.

[0063] The surface roughness of the elastomer film prepared in this example is 9.431.

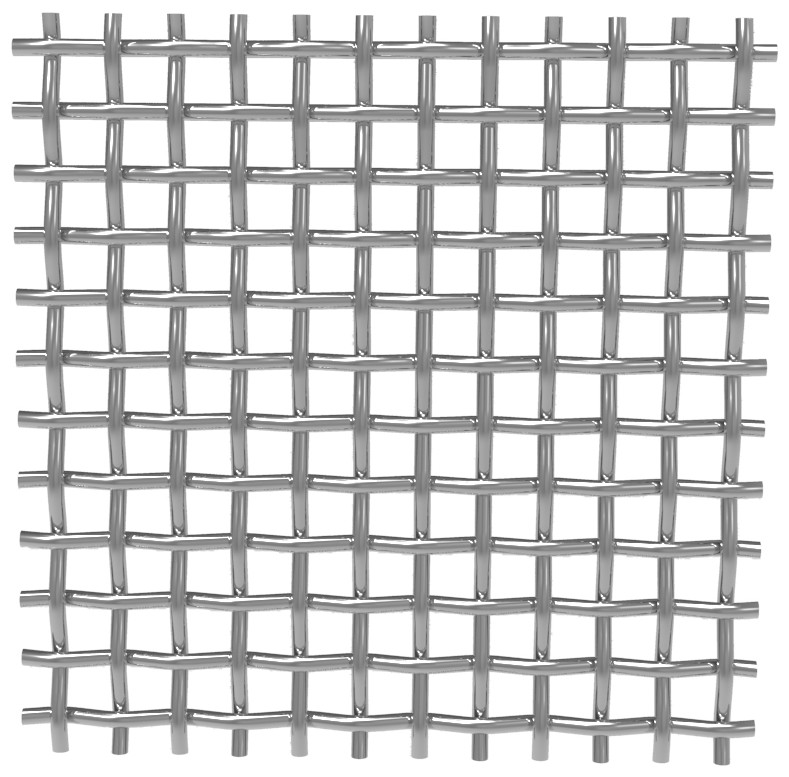

[0064] In the first step, a rectangular iron woven wire mesh with a template length of 40 cm and a width of 20 cm is collected...

Embodiment 2

[0070] A preparation method of an elastomer film with a multi-level microstructure is prepared by the following steps:

[0071] Step 1, processing and customizing the collection template of electrospinning;

[0072] Step 2. Change the receiving device in the electrospinning equipment from a drum to a collection template, and adjust the parameters of the electrospinning equipment;

[0073] Step 3, preparing a thermoplastic polyurethane (TPU) elastomer solution to obtain an electrospinning solution;

[0074] Step 4, extracting the electrospinning liquid, and spinning through the electrospinning equipment; after the spinning is completed, the film is peeled off from the collection template to obtain an elastomeric film with a multi-level microstructure.

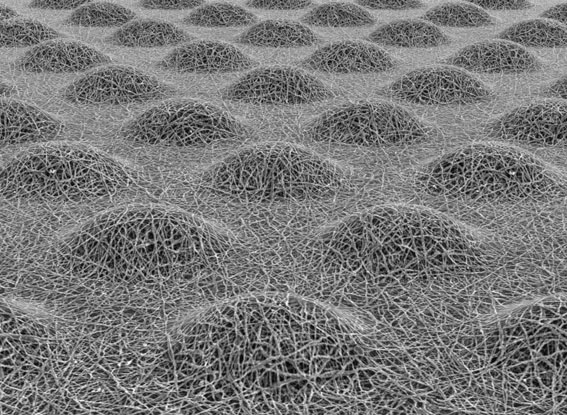

[0075] The elastomer film with multi-level microstructure prepared in this example has regular hill-shaped micro-protrusions on one side and randomly distributed fiber network inside, and its surface roughness is 13.645.

[00...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com