Protonic acid doped polyaniline material and room temperature ammonia gas sensor as well as preparation method

An ammonia gas sensor and polyaniline technology, applied in the field of ammonia gas sensors, can solve the problems of difficulty in widely testing and application of ammonia gas, high cost of electrochemical sensors, complicated sensor technology, etc., and achieve good performance, low power consumption, and expanded application scope. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

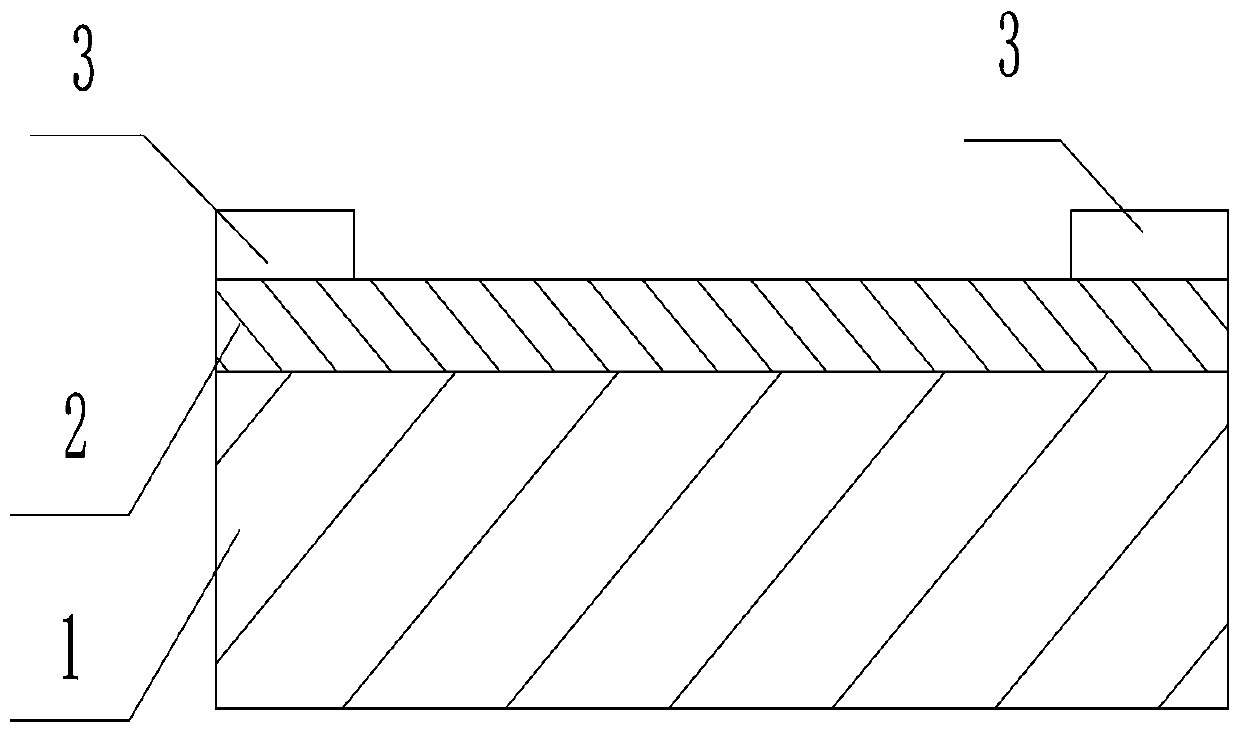

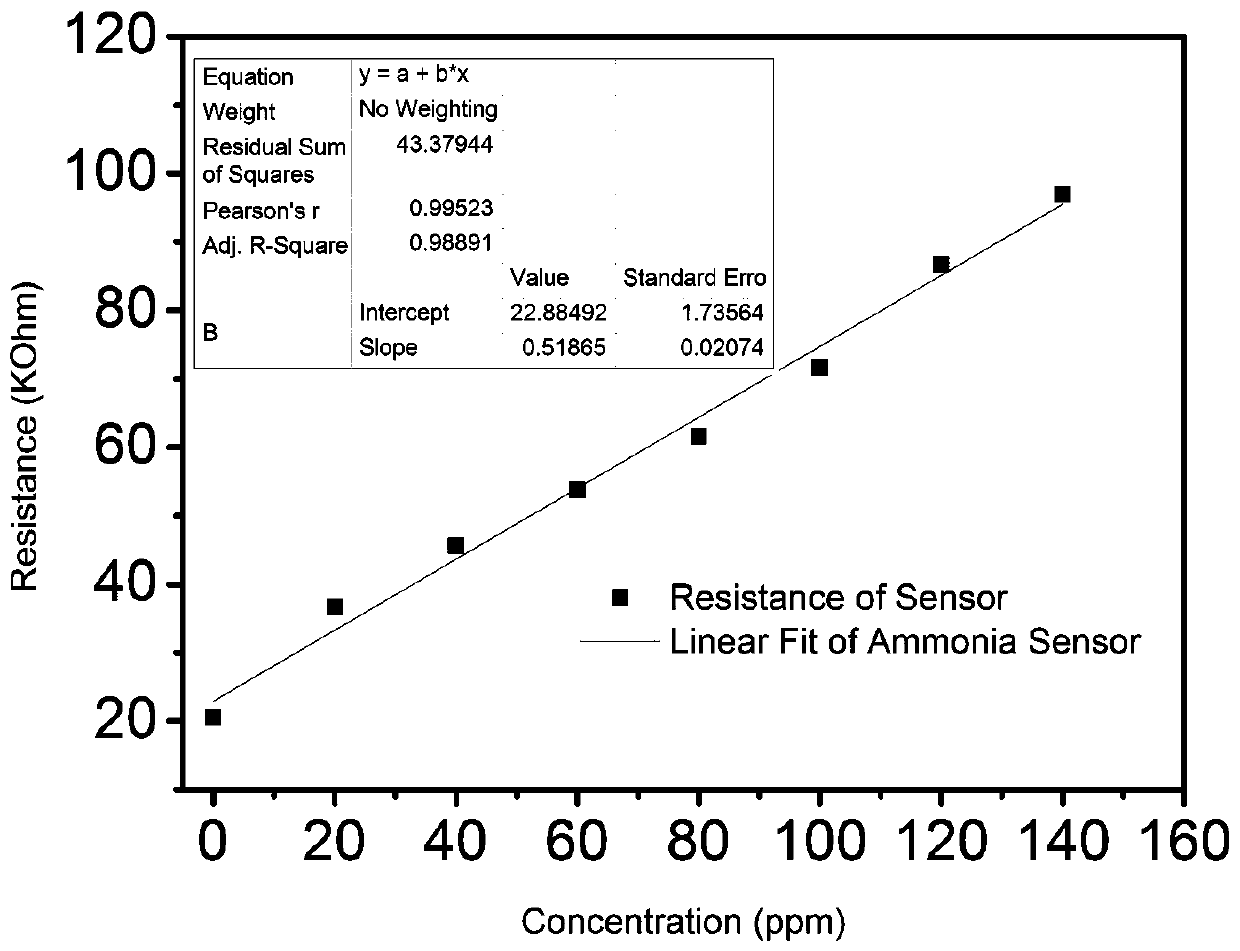

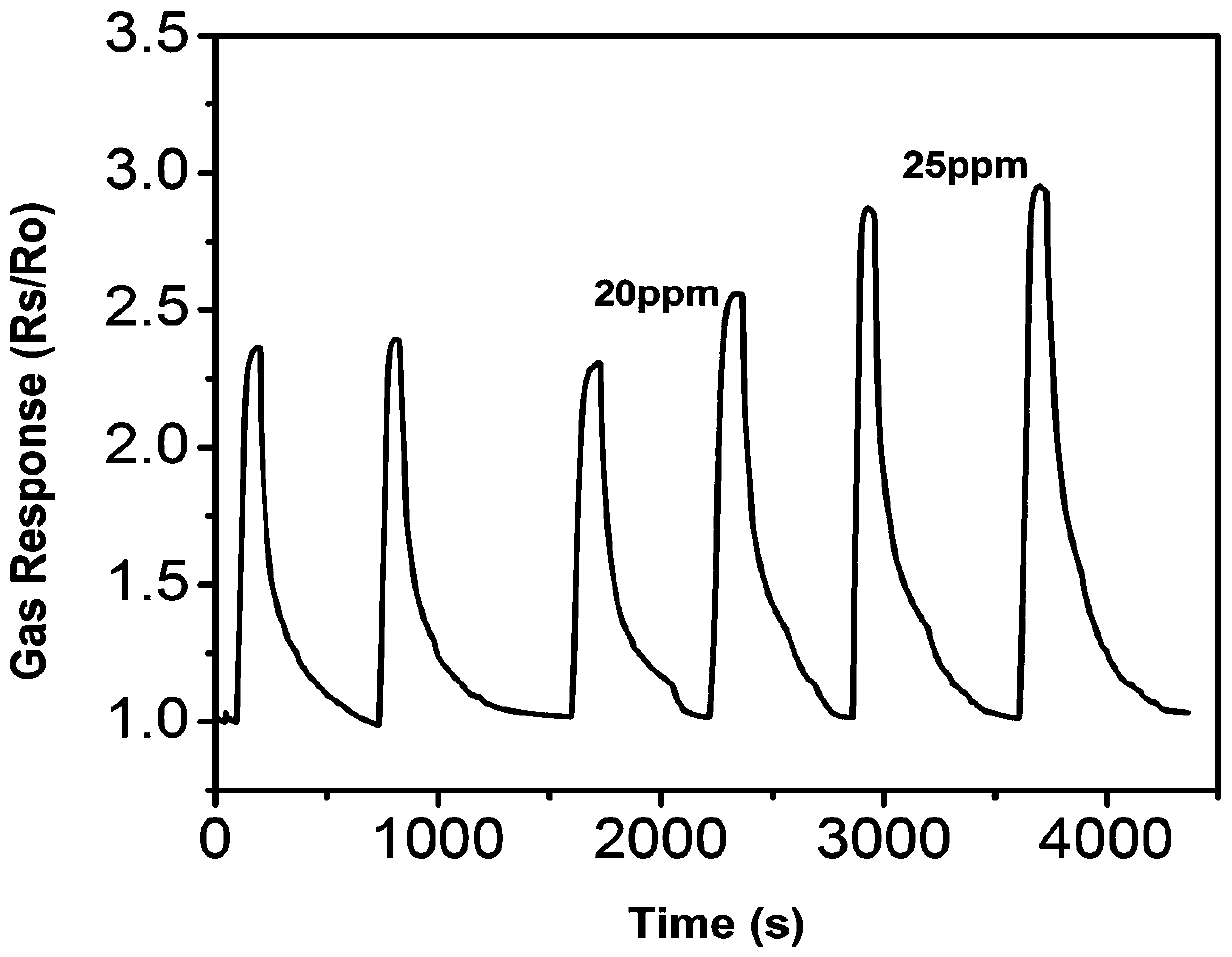

Method used

Image

Examples

Embodiment 1

[0029] This embodiment provides a method for preparing a protonic acid-doped polyaniline material, the preparation steps of which include:

[0030] Mix aniline and protonic acid at room temperature to obtain a premixed solution, add a template agent to the premixed solution, mix under ultrasonic conditions for 10 minutes, and then place it in an ice-water bath for 30 minutes to obtain an ultrasonic dispersion solution. The oxidizing agent is dropped into the oxidizing agent and left to react for 24 hours to obtain a protonic acid-doped polyaniline material; wherein, the protonic acid is oxalic acid, the template agent is chitosan, and the oxidizing agent is hydrogen peroxide; the aniline, the oxalic acid , The molar ratio of the chitosan and the hydrogen peroxide is 1:2.5:2.5:5.

[0031] This embodiment also provides a protonic acid-doped polyaniline material, which is prepared by the above-mentioned preparation method of the protonic acid-doped polyaniline material.

[0032]...

Embodiment 2

[0039] This embodiment provides a method for preparing a protonic acid-doped polyaniline material, the preparation steps of which include:

[0040] Mix aniline and citric acid at room temperature to obtain a premixed solution, add polyethylene oxide to the premixed solution, mix for 3 minutes under ultrasonic conditions, and then place it in an ice-water bath for 20 minutes to obtain an ultrasonic dispersion solution. Ammonium persulfate was dropped into the solution and left to react for 20 hours to prepare protonic acid-doped polyaniline; wherein, the molar ratio of the aniline, the citric acid, the polyethylene oxide and the ammonium persulfate was 1:2 :2:10.

[0041] This embodiment also provides a protonic acid-doped polyaniline material, which is prepared by the preparation method of protonic acid-doped polyaniline.

[0042] This embodiment also provides a method for preparing a room temperature ammonia sensor, the steps of which are roughly the same as those in Embodimen...

Embodiment 3

[0045] This embodiment provides a method for preparing a protonic acid-doped polyaniline material, the preparation steps of which include:

[0046] Mix aniline and sulfuric acid at room temperature to obtain a premixed solution, add polyvinylpyrrolidone to the premixed solution, mix under ultrasonic conditions for 3 minutes and place it in an ice-water bath for 20 minutes to obtain an ultrasonic dispersion solution, add the ultrasonic dispersion solution Ammonium persulfate was added dropwise into the mixture and left to react for 20 hours to obtain polyaniline; wherein, the molar ratio of the aniline, sulfuric acid, polyvinylpyrrolidone and the ammonium persulfate was 1:2:2.5:10.

[0047] This embodiment also provides a protonic acid-doped polyaniline material, which is prepared by the above-mentioned preparation method of protonic acid-doped polyaniline.

[0048] This embodiment also provides a method for preparing a room temperature ammonia sensor, the steps of which are ro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com