Method for preparing copper-zinc-tin-sulfide solar cell absorbing layer with homogeneous solution method

A solar cell, copper-zinc-tin-sulfur technology, applied in circuits, electrical components, final product manufacturing, etc., can solve problems such as unfavorable production applications, highly toxic hydrazine, poor safety, etc., to achieve strong repeatability, low cost, Avoiding the effect of residual carbon

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

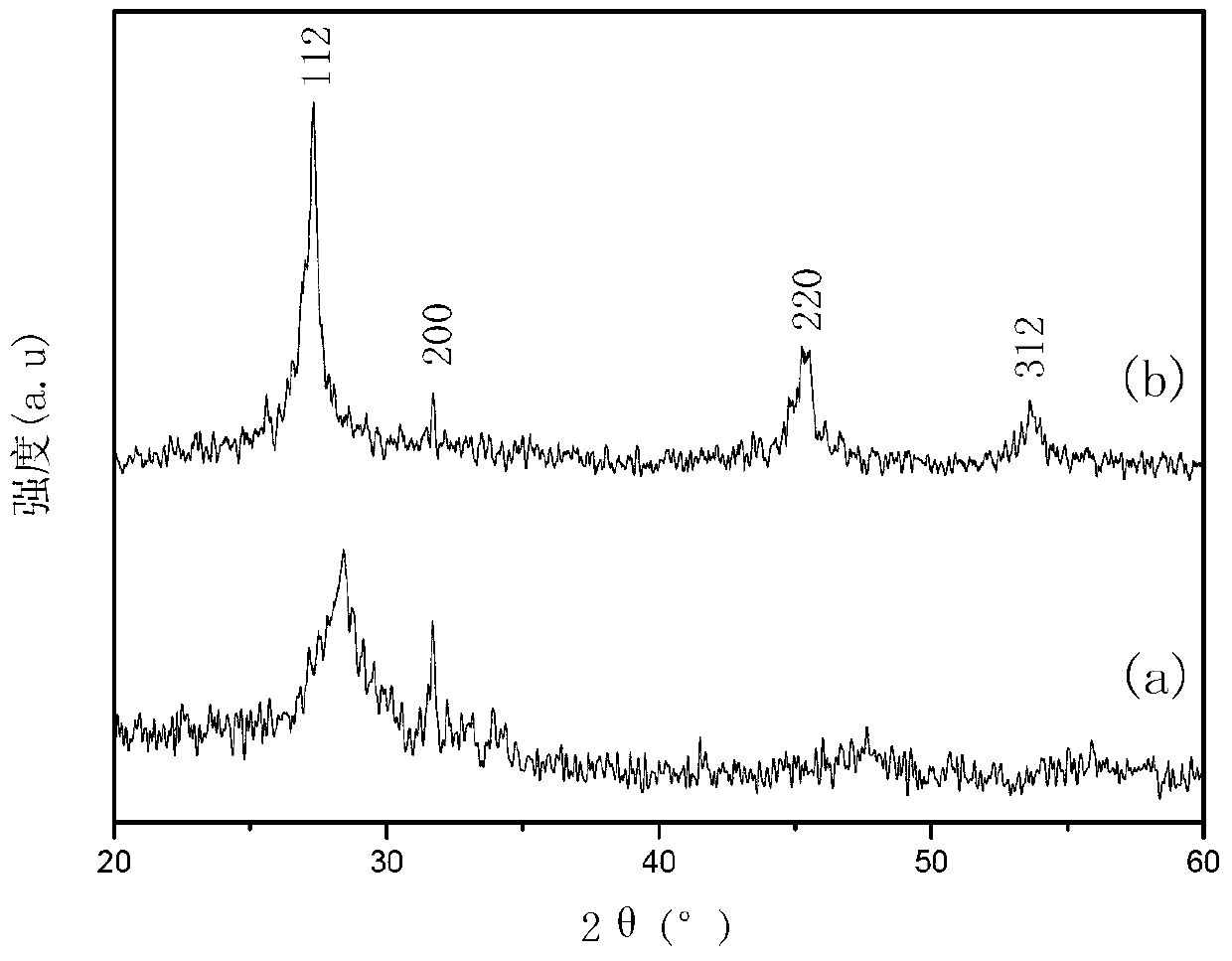

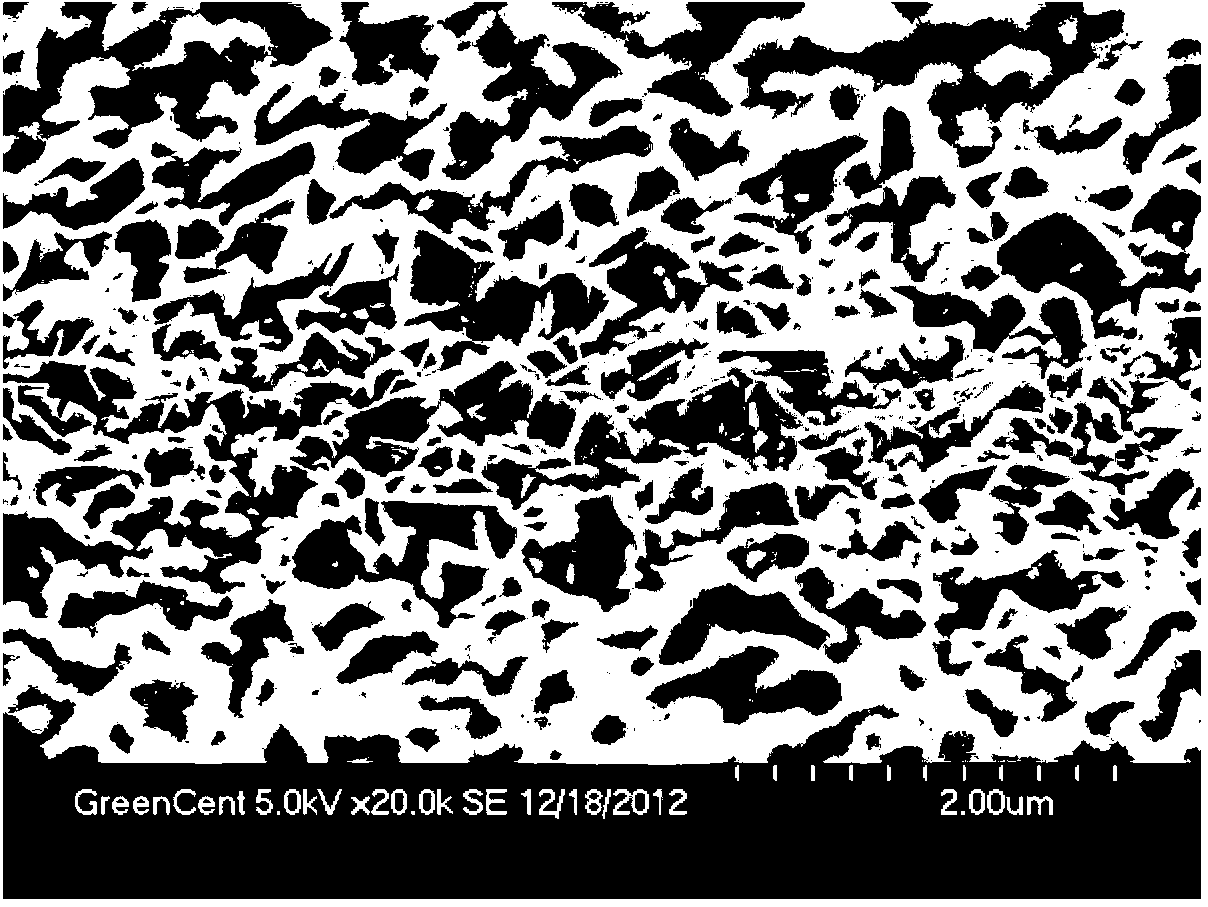

Embodiment 1

[0027] 1) Add 1.0230g CuCl 2 2H 2 O, 0.4089g ZnCl 2 , 0.6769g SnCl 2 2H 2 O, 1.8031g TAA was successively dissolved in 20ml isopropanol solvent, fully stirred at room temperature until a pale yellow transparent solution was formed;

[0028] 2) Immerse the soda-lime glass on the Mo-coated substrate in the above transparent solution, pull it out of the liquid surface, place the glass piece at an angle for 2 minutes, put it in an oven at 150°C, and dry it for 10 minutes under non-blast condition;

[0029] 3) Repeat step 2) to immerse, lift and dry the film 6 times;

[0030] 3) Place the obtained precursor film sample and sulfur powder in a graphite box, place the sulfur powder in the groove below the film sample, sulfur vapor can fill the entire graphite box through the slot, and place the graphite box in a tubular annealing furnace. in N 2 The annealing treatment is carried out under the protection of atmosphere, and the whole vulcanization annealing process is controlled ...

Embodiment 2

[0033] 1) Add 1.0230g CuCl 2 2H 2 O, 0.4089g ZnCl 2 , 0.6769g SnCl 2 2H 2 O, 1.8031g TAA was successively dissolved in 20ml isopropanol solvent, fully stirred at room temperature until a pale yellow transparent solution was formed;

[0034]2) Immerse the soda-lime glass on the Mo-coated substrate in the above transparent solution, pull it out of the liquid surface, place the glass piece at an angle for 2 minutes, put it in an oven at 150°C, and dry it for 10 minutes under non-blast condition;

[0035] 3) Repeat step 2) to immerse, lift and dry the film 6 times;

[0036] 3) Place the obtained precursor film sample and selenium particles in a graphite box, place the selenium particles in the groove below the film sample, the selenium vapor can fill the entire graphite box through the slot, and place the graphite box in a tubular annealing furnace. in N 2 The annealing treatment is carried out under the protection of atmosphere, and the whole vulcanization annealing process...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com