Polymer-based hyperbranched metal phthalocyanine@nano-barium titanate composite material as well as preparation method and application thereof

A technology of metal phthalocyanine and composite materials, which is applied in the field of polymer-based hyperbranched metal phthalocyanine@nano-barium titanate composite materials and its preparation, can solve the problems of limited performance, poor compatibility, and uneven distribution of composite materials. Achieve the effect of avoiding separation, ensuring stability and tightness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

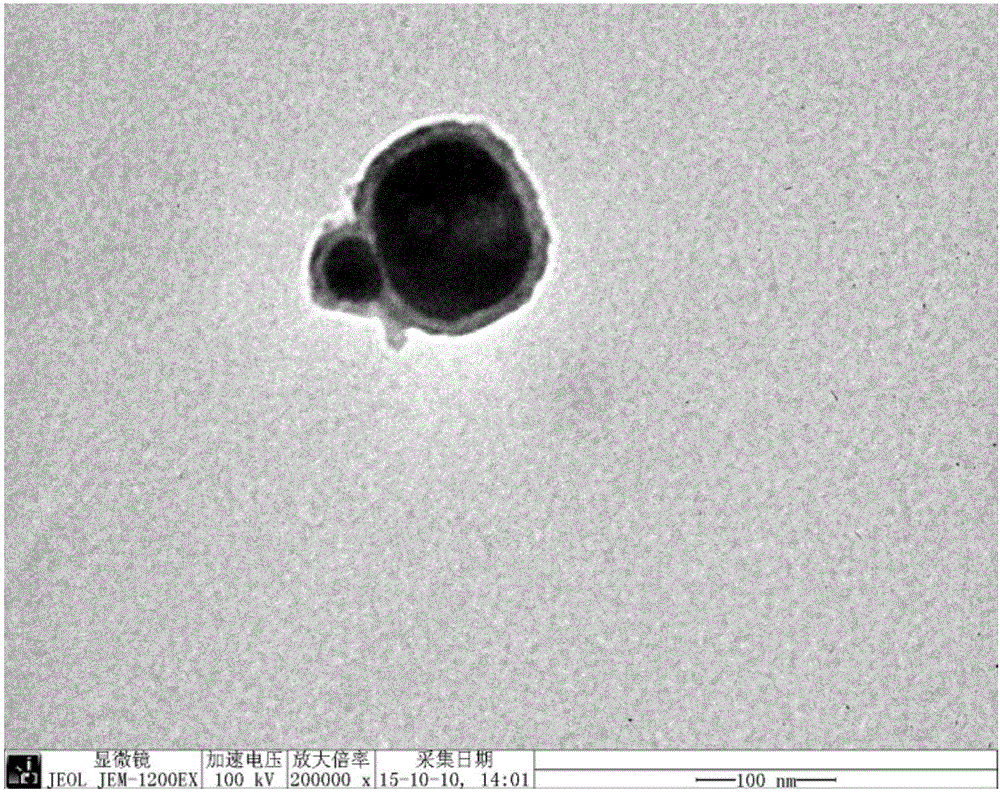

[0070] Step 1, ultrasonically disperse 10 g of barium titanate nanoparticles with a particle size between 50 and 200 nm in 350 mL of hydrogen peroxide solution (concentration: 30 vol%) for 1 hour, stir at a temperature of 105 ° C for 4 hours, and then It is separated under the condition of 3000r / min and dried under the condition of vacuum at 60°C to prepare highly active nano barium titanate;

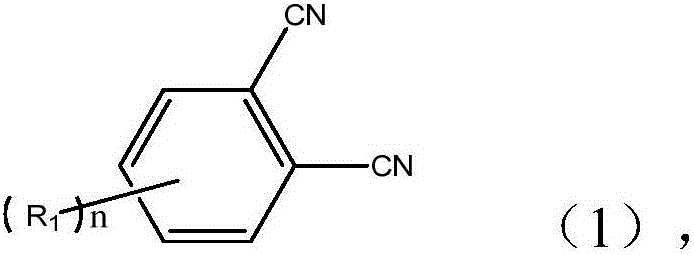

[0071] Step 2, ultrasonically disperse 8 g of the above-mentioned highly active nanobarium titanate nanoparticles in 250 mL of N,N-dimethylformamide for 1 hour, then add 1.6 g of 4-nitrophthalonitrile, 2.4 g of Potassium carbonate water, and stirred at a temperature of 80°C for 8 hours, then separated at a centrifugal speed of 3000r / min, and dried in vacuum at 60°C to prepare cyanated nano barium titanate;

[0072] Step 3, ultrasonically disperse 5 g of the above-mentioned cyanated nanobarium titanate in 200 mL of N,N-dimethylformamide for 1 hour, then add 0.25 g of cuprous chloride and...

Embodiment 2

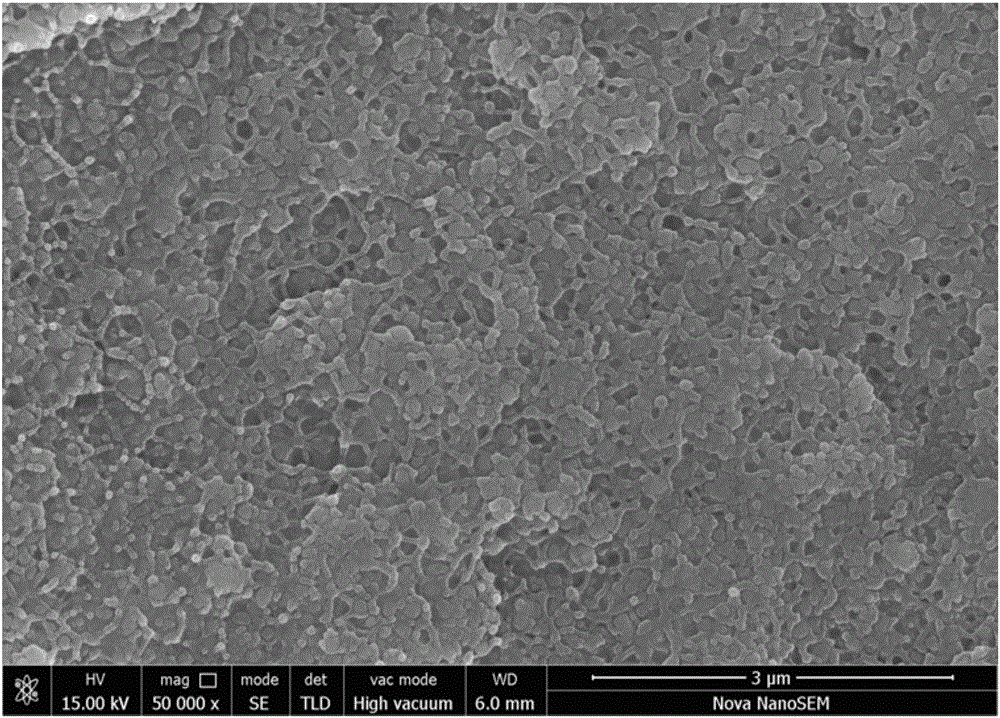

[0081] Other steps are as described in Example 1, the only difference is that the amount of hyperbranched metal phthalocyanine@nano barium titanate particles with a core-shell structure in step 4 is changed to 0.3934g, and the amount of polyethersulfone is changed to 0.3226g, That is, the polymer-based hyperbranched metal phthalocyanine@nano barium titanate composite material was obtained.

[0082] In the hyperbranched metal phthalocyanine@nano-barium titanate particles with core-shell structure prepared in this example, the mass ratio of the inner core nano-barium titanate to the outer shell hyperbranched metal phthalocyanine is 92:8.

[0083] In the polymer-based hyperbranched metal phthalocyanine@nano barium titanate composite material prepared in the embodiment of the present invention, the mass ratio of polyethersulfone and hyperbranched metal phthalocyanine@nano barium titanate particles with a core-shell structure is 45: 55, wherein the volume ratio of polyethersulfone:...

Embodiment 3

[0086]Other steps are as described in Example 1, the only difference is that the amount of hyperbranched metal phthalocyanine@nano barium titanate particles with a core-shell structure in step 4 is changed to 0.5901g, and the amount of polyethersulfone is changed to 0.2823g, That is, the polymer-based hyperbranched metal phthalocyanine@nano barium titanate composite material was obtained.

[0087] In the hyperbranched metal phthalocyanine@nano-barium titanate particles with core-shell structure prepared in this example, the mass ratio of the inner core nano-barium titanate to the outer shell hyperbranched metal phthalocyanine is 92:8.

[0088] In the polymer-based hyperbranched metal phthalocyanine@nano barium titanate composite material prepared in the embodiment of the present invention, the mass ratio of polyethersulfone and hyperbranched metal phthalocyanine@nano barium titanate particles with a core-shell structure is 32: 68, wherein the volume ratio of polyethersulfone: ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Intrinsic viscosity | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com