Preparation method of different stack layer carbon fiber cloth/TPU composite material with high electromagnetic shielding performance

A carbon fiber cloth and electromagnetic shielding technology, which is applied in the field of preparation of different stacked layers of carbon fiber cloth/TPU composite materials, can solve the problems of poor alignment of conductive fillers, limited electromagnetic shielding performance, inconsistent axial orientation, etc. Excellent shielding performance, excellent electromagnetic shielding performance, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

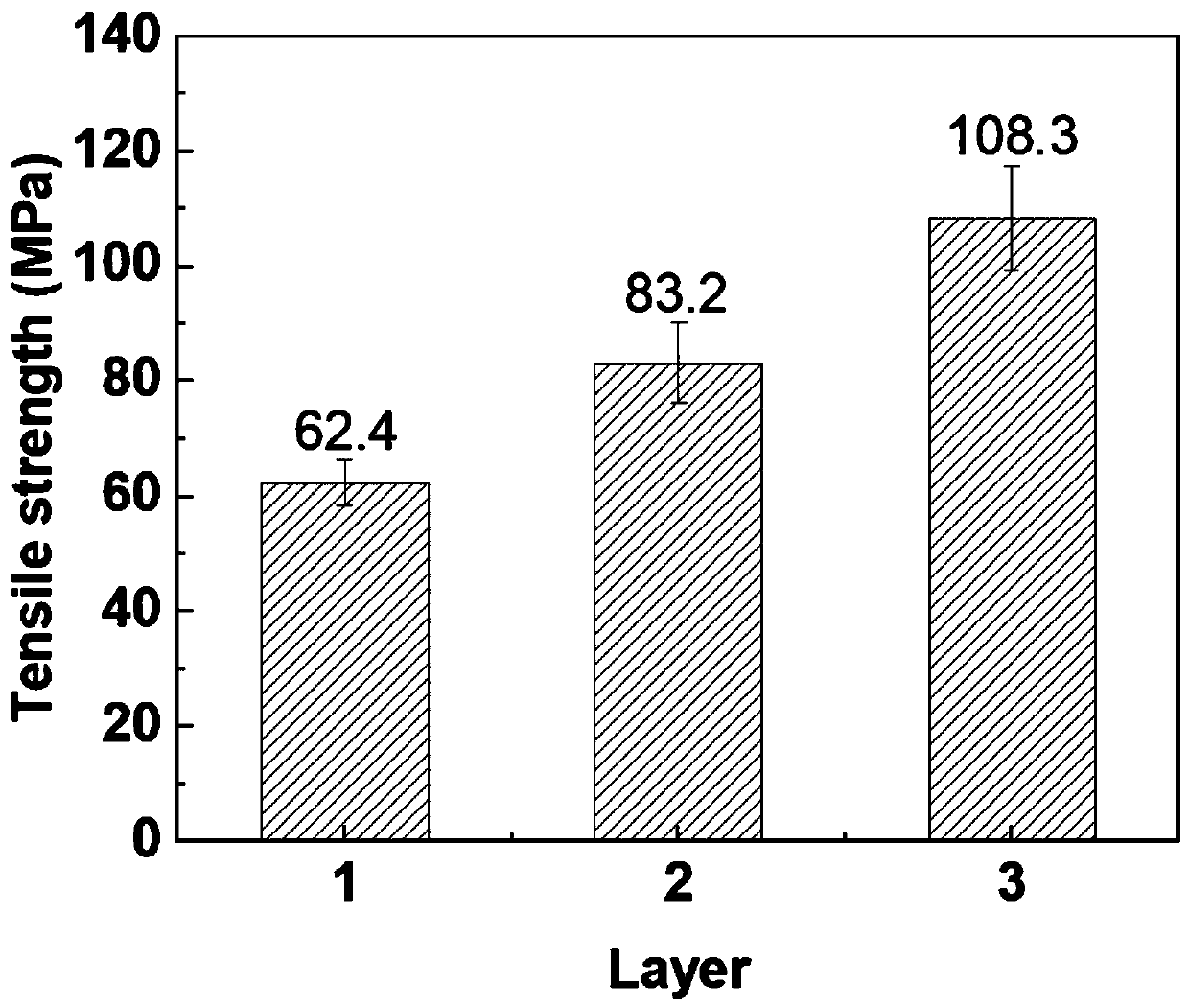

Embodiment 1

[0057] The first step is to place the carbon fiber cloth in an ultrasonic cleaning machine for a small cleaning, and the cleaning time is 2 hours.

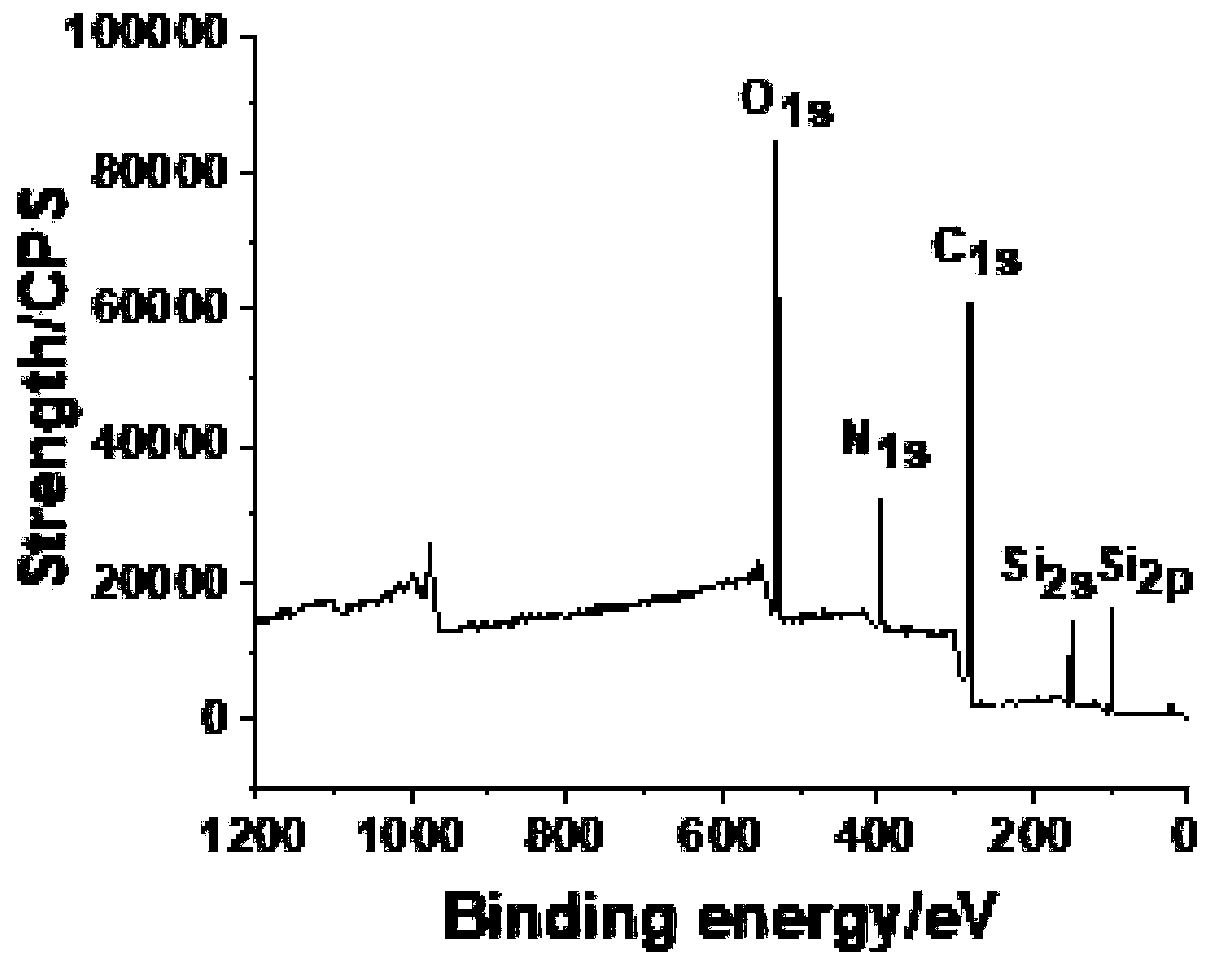

[0058] In the second step, place the cleaned carbon fiber cloth in a beaker filled with a mixture of absolute ethanol and silane coupling agent KH-550 (the mass ratio of absolute ethanol to silane coupling agent KH-550 is 4:1) Surface modification of carbon fiber cloth was carried out, and the beaker was placed in a constant temperature water bath at 80°C for 2 hours.

[0059] The third step is to take out the surface-modified carbon fiber cloth, wash it with distilled water, and then place it in a drying oven for drying treatment. The drying temperature is 100°C and the drying time is 2 hours. Then take it out and seal it.

[0060] For the fourth cloth, place the TPU particles in a drying oven for 2 hours for drying treatment, and the temperature is set at 100°C.

[0061] The fifth step is to fill the mold with TPU granules, an...

Embodiment 2

[0065] The first step is to place the carbon fiber cloth in an ultrasonic cleaning machine for a small cleaning, and the cleaning time is 2 hours.

[0066] In the second step, place the cleaned carbon fiber cloth in a beaker filled with a mixture of absolute ethanol and silane coupling agent KH-550 (the mass ratio of absolute ethanol to silane coupling agent KH-550 is 4:1) Surface modification of carbon fiber cloth was carried out, and the beaker was placed in a constant temperature water bath at 80°C for 2 hours.

[0067] The third step is to take out the surface-modified carbon fiber cloth, wash it with distilled water, and then place it in a drying oven for drying treatment. The drying temperature is 100°C and the drying time is 2 hours. Then take it out and seal it.

[0068] For the fourth cloth, place the TPU particles in a drying oven for 2 hours for drying treatment, and the temperature is set at 100°C.

[0069] The fifth step is to fill the mold with TPU granules, an...

Embodiment 3

[0072] The first step is to place the carbon fiber cloth in an ultrasonic cleaning machine for a small cleaning, and the cleaning time is 2 hours.

[0073] In the second step, place the cleaned carbon fiber cloth in a beaker filled with a mixture of absolute ethanol and silane coupling agent KH-550 (the mass ratio of absolute ethanol to silane coupling agent KH-550 is 4:1) Surface modification of carbon fiber cloth was carried out, and the beaker was placed in a constant temperature water bath at 80°C for 2 hours.

[0074] The third step is to take out the surface-modified carbon fiber cloth, wash it with distilled water, and then place it in a drying oven for drying treatment. The drying temperature is 100°C and the drying time is 2 hours. Then take it out and seal it.

[0075] For the fourth cloth, place the TPU particles in a drying oven for 2 hours for drying treatment, and the temperature is set at 100°C.

[0076] The fifth step is to fill the mold with TPU granules, an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com