Copper oxide/carbon nanofiber/sulfur electrode material and preparation and application thereof

A technology of carbon nanofibers and copper oxides, applied in nanocarbons, battery electrodes, circuits, etc., can solve problems such as high cost, poor performance, and complicated preparation process, and achieve low cost, improve cycle performance and capacity, and improve cycle Performance and Stability Effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

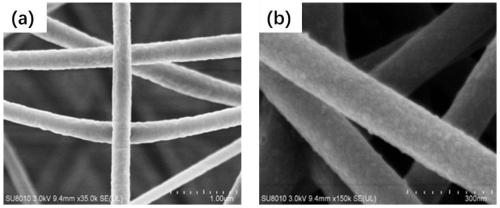

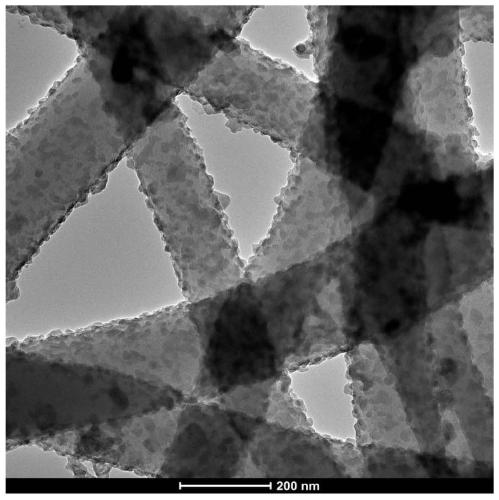

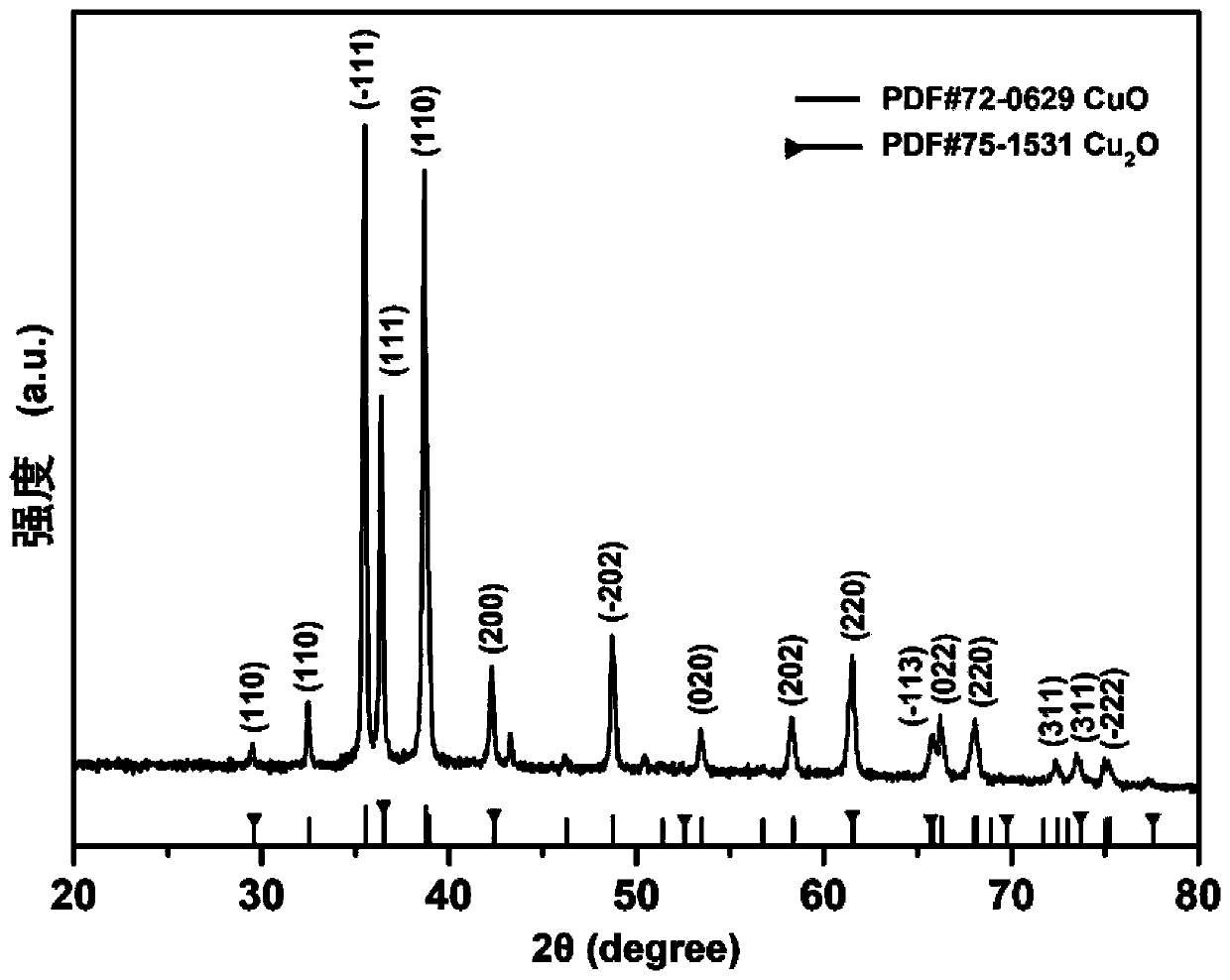

[0038] (1) Dissolve 0.1g of anhydrous copper acetate powder in 9.0g of N,N-dimethylformamide solution, stir magnetically at room temperature for 1h to obtain a uniform and stable solution, then add 1.0g of polyacrylonitrile powder, and stir magnetically for 10h And ultrasonic treatment 2h, obtain electrospinning stock solution; Carry out electrospinning (environmental humidity is 30%, and ambient temperature is 25 ℃, and spinning solution propulsion speed is 10.mL / h, and the distance between needle and receiving aluminum foil is 15cm , the voltage between the needle and the receiving aluminum foil is 18kV) to obtain a copper acetate / polyacrylonitrile nanofiber membrane, which is placed in a vacuum oven at 60°C for 24h.

[0039] (2) heat-treat the copper acetate / polyacrylonitrile nanofiber membrane obtained by electrospinning in a muffle furnace at a temperature of 280°C and a heat-treatment time of 4 hours; The temperature is 600° C., and the heat treatment time is 1 h to obta...

Embodiment 2

[0047] (1) Dissolve 0.3g of anhydrous copper acetate powder in 9.0g of N,N-dimethylformamide solution, stir magnetically at room temperature for 1h to obtain a uniform and stable solution, then add 1.0g of polyacrylonitrile powder, and stir magnetically for 10h And ultrasonic treatment 2h, obtain electrospinning stock solution; Carry out electrospinning (environmental humidity is 30%, and ambient temperature is 25 ℃, and spinning solution propulsion speed is 10.mL / h, and the distance between needle and receiving aluminum foil is 15cm , the voltage between the needle and the receiving aluminum foil is 18kV) to obtain a copper acetate / polyacrylonitrile nanofiber membrane, which is placed in a vacuum oven at 60°C for 24h.

[0048] (2) heat-treat the copper acetate / polyacrylonitrile nanofiber membrane obtained by electrospinning in a muffle furnace at a temperature of 280°C and a heat-treatment time of 4 hours; The temperature is 600° C., and the heat treatment time is 1 h to obta...

Embodiment 3

[0054] (1) Dissolve 0.1g of anhydrous copper acetate powder in 9.0g of N,N-dimethylformamide solution, stir magnetically at room temperature for 1h to obtain a uniform and stable solution, then add 1.0g of polyacrylonitrile powder, and stir magnetically for 10h And ultrasonic treatment 2h, obtain electrospinning stock solution; Carry out electrospinning (environmental humidity is 30%, and ambient temperature is 25 ℃, and spinning solution propulsion speed is 10.mL / h, and the distance between needle and receiving aluminum foil is 15cm , the voltage between the needle and the receiving aluminum foil is 18kV) to obtain a copper acetate / polyacrylonitrile nanofiber membrane, which is placed in a vacuum oven at 60°C for 24h.

[0055] (2) heat-treat the copper acetate / polyacrylonitrile nanofiber membrane obtained by electrospinning in a muffle furnace at a temperature of 280°C and a heat-treatment time of 4 hours; The temperature is 700° C., and the heat treatment time is 1 h to obta...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fiber diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com