Thrust roller bearing with races

A technology of thrust roller bearings and belt seats, applied in the direction of roller bearings, bearings, bearing components, etc., can solve problems such as difficult functions, coexistence, and less lubricating oil flow, and achieve good handling effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

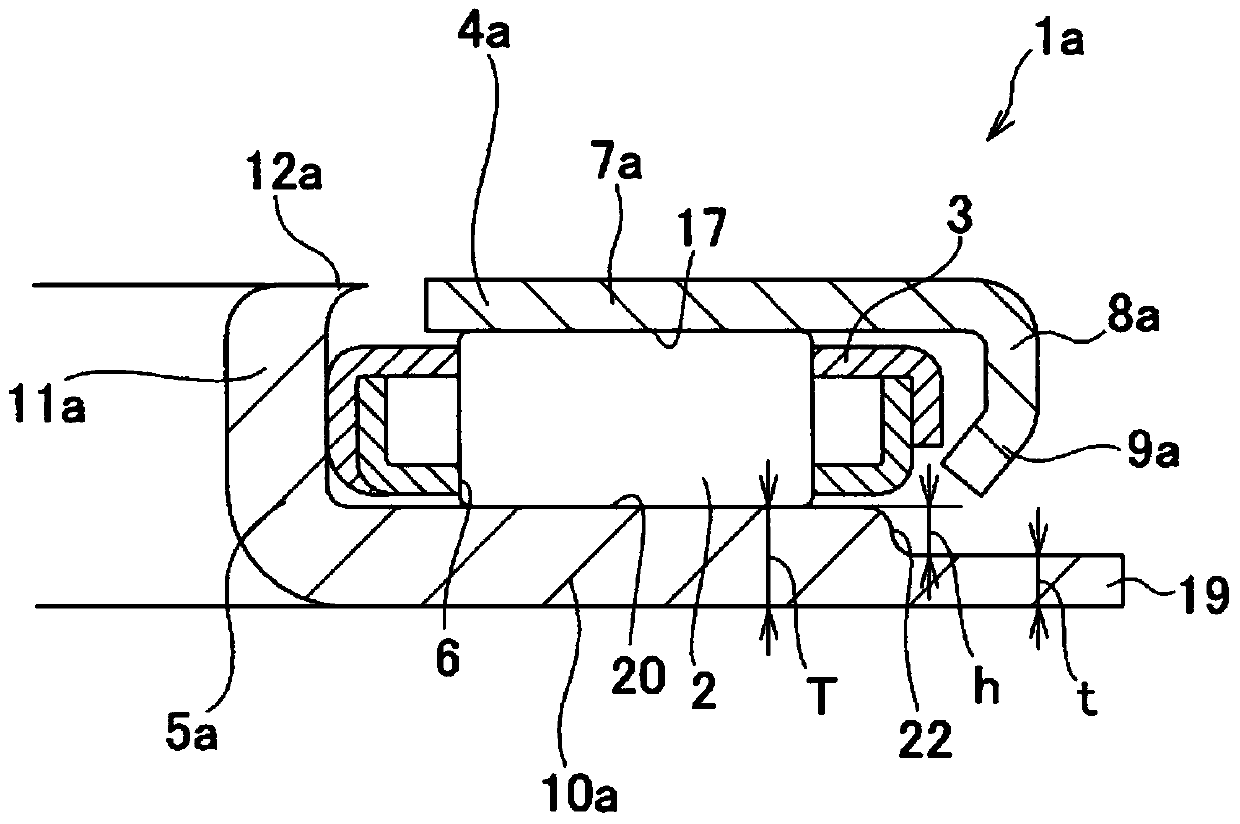

[0085] See Table 1, Table 2, Figure 5 as well as Image 6 , an experiment conducted to confirm the effect of the present invention will be described. Among them, Table 1 and Figure 5 A test for determining the influence of the size of the internal clearance of a thrust roller bearing with a race on the durability in a state where the first thrust race and the second thrust race are operated eccentrically from each other (eccentricity test ) and a test to find out the influence of the size of the internal space of a thrust bearing with a race on the durability of the operating state in which the thrust load state and the unloaded state are alternately repeated (load ON / OFF test) conditions and results of the two experiments. The conditions common to both tests are as follows.

[0086] Outer diameter of thrust roller bearing with race: 85mm

[0087] Inner diameter of thrust roller bearing with race: 54mm

[0088] Axial thickness (bearing width) of thrust roller bearing w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com