Integrated multifunctional micro-electro-mechanical sensor

A micro-electromechanical sensor and multi-functional technology, which is applied in the direction of electric solid-state devices, generators/motors, microelectronic microstructure devices, etc., can solve the problems of increased volume of micro-electromechanical sensors, redundant internal circuits, and difficult compatibility of signal interference factors. Issues such as clarification and assurance are obtained, and the effects of reducing the horizontal layout area, compact integrated layout design, and reducing signal mutual interference are achieved.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] In order to solve the problems of miniaturization and working stability of the multifunctional microelectromechanical sensor, the present application provides an integrated multifunctional microelectromechanical sensor.

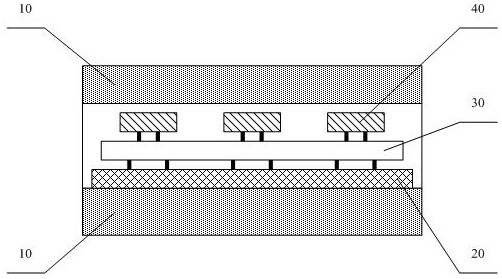

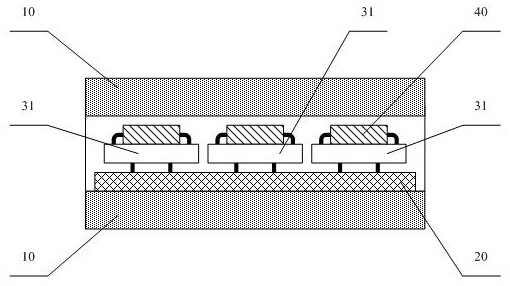

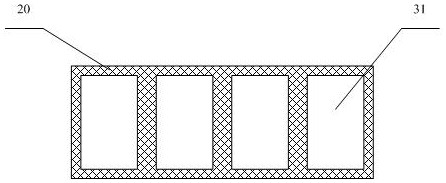

[0038] Such as figure 1 As shown, the integrated multifunctional micro-electromechanical sensor of the present invention includes a package structure 10, and an analog-to-digital conversion electronic wafer 20, a multi-channel signal acquisition electronic wafer 30 and a plurality of micro-electromechanical sensing elements 40 arranged in the package structure , each microelectromechanical sensor element 40 can be used to sense a different equipment status monitoring signal; an analog-to-digital conversion circuit with a plurality of analog signal input ports is formed on the analog-to-digital conversion electronic wafer 20, which is used to separately detect signals from each The analog signal at the signal input port is processed by analog-to-digital...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com