An integrated edge calculator for condition monitoring based on MEMS sensor fusion

A micro-electromechanical sensor, an integrated technology, is applied in the direction of electric solid devices, generators/motors, components of TV systems, etc., which can solve the problems of redundant internal circuits, difficult compatibility of signal mutual interference factors, and increased volume of micro-electromechanical sensors. and other problems, to achieve the effect of reducing the horizontal layout area, improving the work stability, and reducing the problem of signal mutual interference.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] In order to solve the problems of miniaturization and working stability of the condition monitoring edge calculator applied to industrial Internet of Things equipment monitoring, this application provides an integrated condition monitoring edge calculator based on micro-electromechanical sensor fusion.

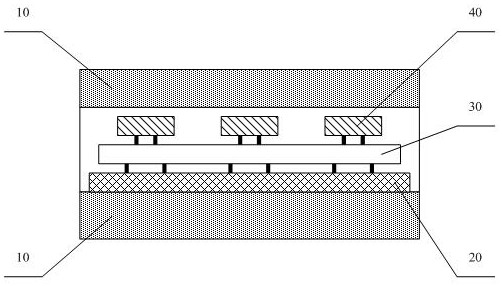

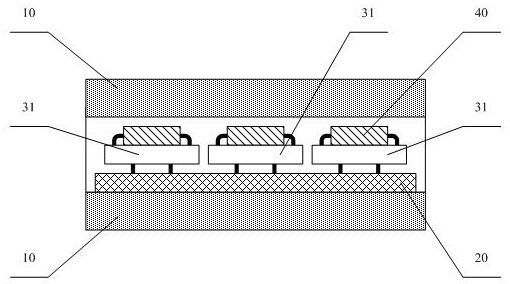

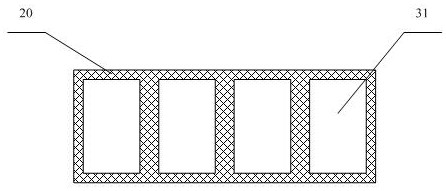

[0042] like figure 1 As shown, the integrated condition monitoring edge calculator of the present invention includes a packaging structure 10, and a calculation processing electronic wafer 20, a multi-channel signal acquisition electronic wafer 30 and a plurality of micro-electromechanical sensing elements 40 arranged in the packaging structure, Each microelectromechanical sensor element 40 can be used to sense a different equipment status monitoring signal; the multi-channel signal acquisition electronic wafer 30 is arranged on the computing and processing electronic wafer, and multi-channel signal acquisition electronic wafer 30 is formed with multiple The signal acqu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com