Heating method of glass batch

A glass batch material and heating method technology, which is applied in glass furnace equipment, glass manufacturing equipment, manufacturing tools, etc., can solve the problems of increased solid particle concentration, increased flue gas dust removal load, and increased glass preparation cost, etc., to reduce the amount of raw materials , reduce the preparation cost, the effect of reducing the preparation cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

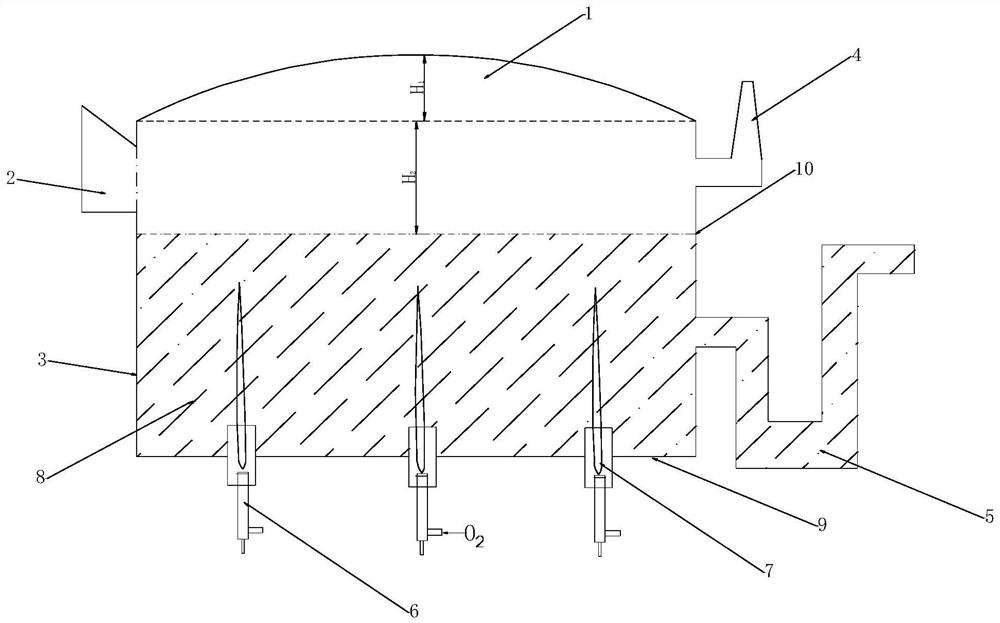

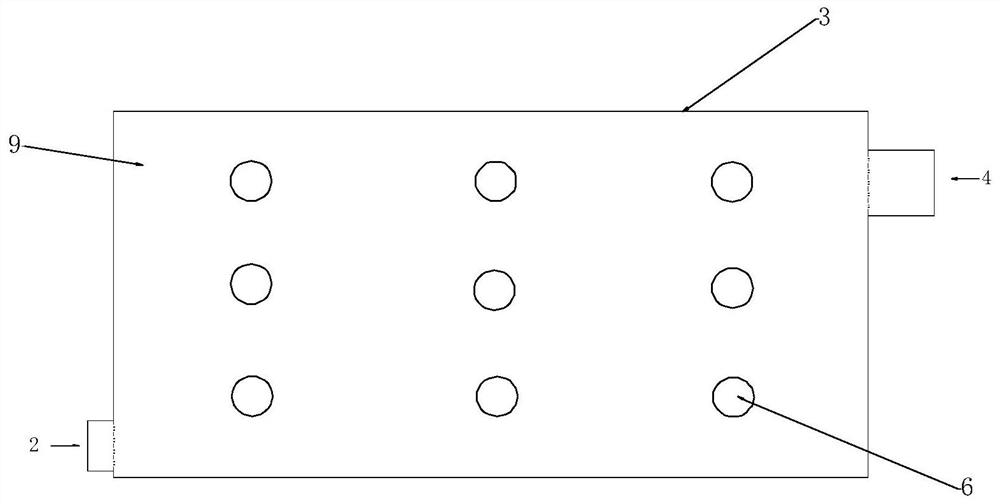

Method used

Image

Examples

Embodiment 1

[0037] Example 1: refractory glass

[0038] Use an external fire to ignite the combustion spray gun at the bottom of the melting pool, and control the fuel consumption of the combustion spray gun to 1 / 15-1 / 10 of the fuel consumption during normal combustion, and pass the cullet and glass batch materials with the same composition as the target glass product in sequence The feeding port is added to the melting pool, and with the increase of the glass batch in the melting pool, the fuel consumption will increase accordingly, and after the temperature reaches the melting temperature of the glass, continue to burn to stabilize the liquid level of the glass; at this time, continue to burn, on the one hand It is to ensure the stability of the melting temperature. On the other hand, it is to make the combustion products play a clarification role, so as to reduce the amount of clarifier or even not use clarifier on the premise of ensuring the quality of glass melting. When heating refr...

Embodiment 2

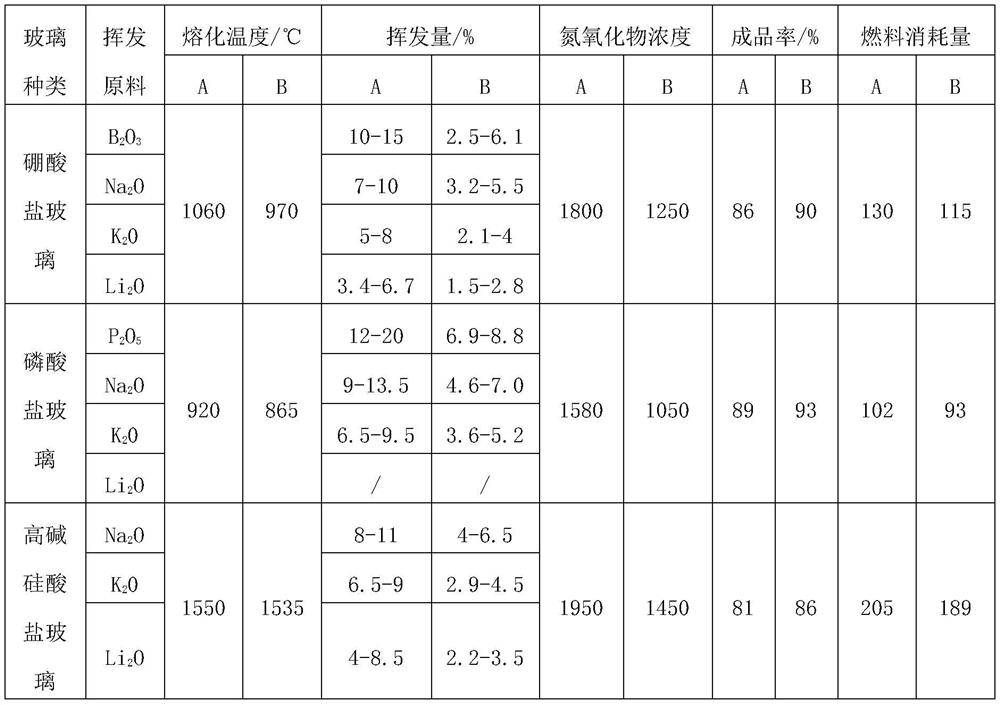

[0039] Embodiment two: volatile glass

[0040] Use an external fire to ignite the combustion spray gun at the bottom of the melting pool, and control the fuel consumption of the combustion spray gun to 1 / 15-1 / 10 of the fuel consumption during normal combustion, and pass the cullet and glass batch materials with the same composition as the target glass product in sequence The feeding port is added to the melting pool. With the increase of the glass batch in the melting pool, the fuel consumption will increase accordingly. After the temperature reaches the melting temperature of the glass, continue to burn to stabilize the liquid level of the glass liquid; continuing to burn will promote the overall glass liquid Flip from bottom to top to speed up the homogenization of the molten glass, which will reduce the temperature difference between the upper and lower sides of the molten glass (the original heating method burns the spray gun on the side wall, the glass liquid surface tempe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com