Catalytic reduction type de-nitrification reactor of circulating fluidized bed

A denitration reactor and circulating fluidized bed technology, which is applied in chemical instruments and methods, separation methods, chemical/physical processes, etc., can solve the problem of catalysts easily coming out of the fluidized bed, etc., and reduce the floor space and investment cost. , improve the utilization rate, the effect of sufficient response

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

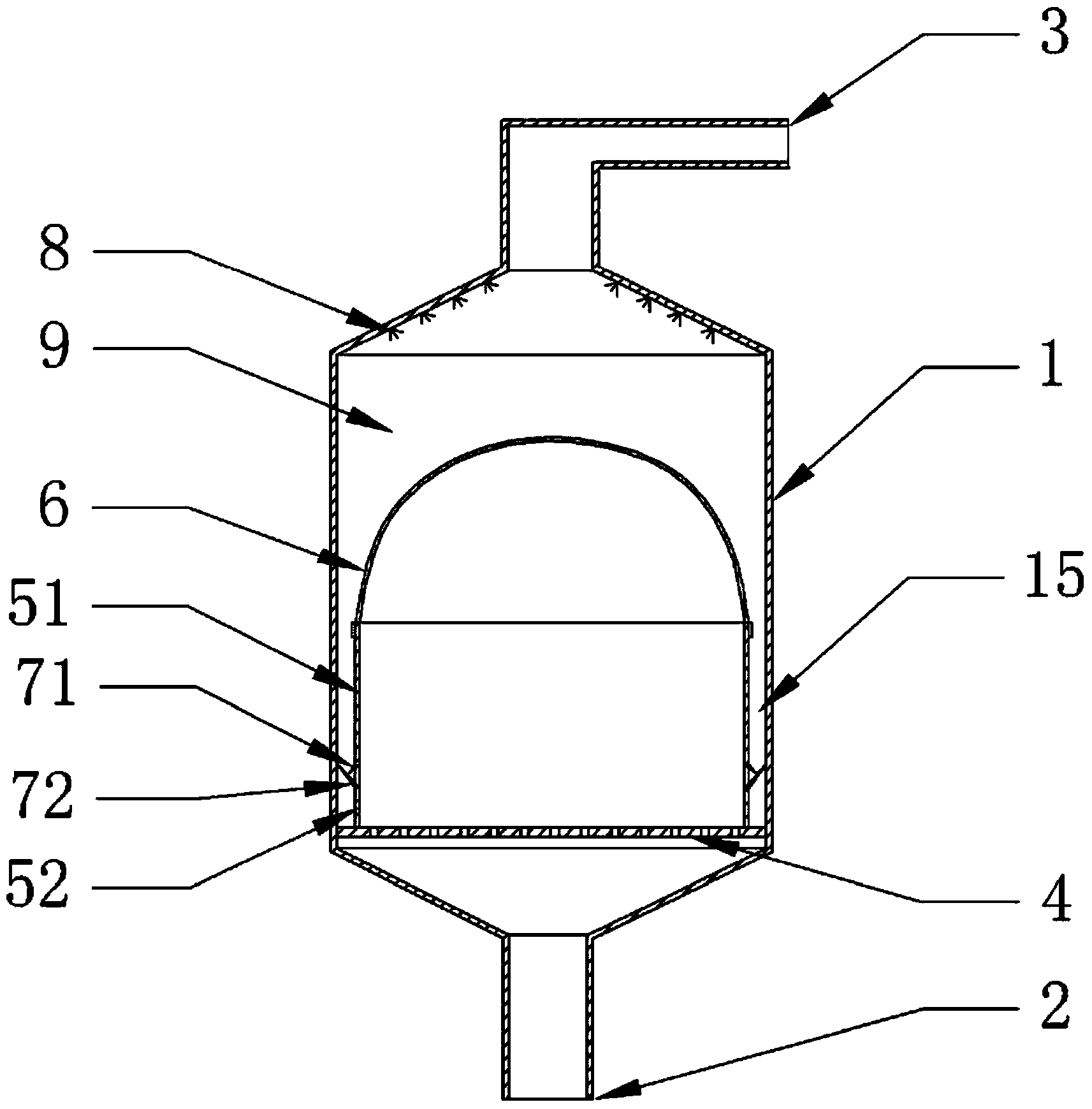

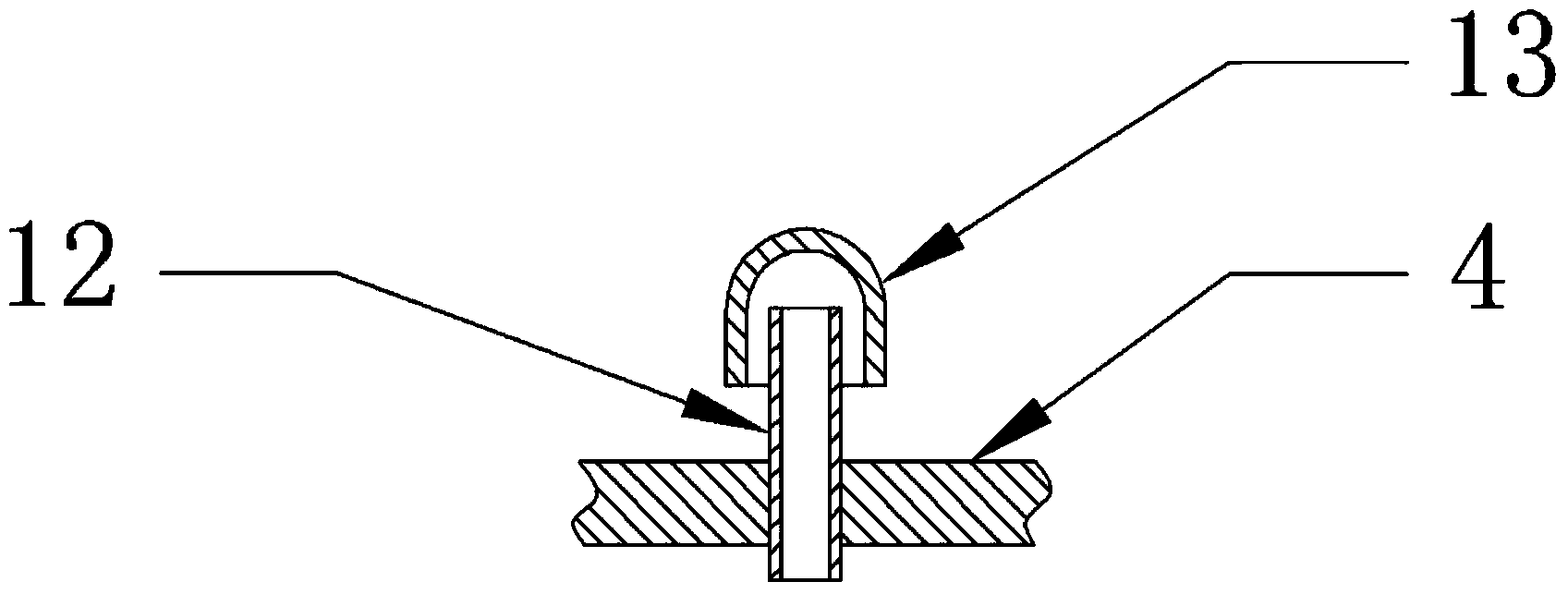

[0024] The circulating fluidized bed catalytic reduction method denitrification reactor of embodiment 1, such as figure 1 As shown, it includes a reactor shell 1 with a reactor cavity 9, the bottom and top of the reactor shell 1 are respectively provided with an inlet flue 2 and an outlet flue 3 communicating with the reactor cavity 9, the The lower part of the reactor inner cavity 9 is provided with an air distribution plate 4 with air distribution holes, and above the air distribution plate 4 in the reactor inner cavity 9, there is a wall closed with the top, and the lower part has a downward opening for intercepting The filter container of the catalyst, the container wall of the filter container is provided with filter holes; in this embodiment, the filter container is made of a support cylinder and a filter bag 6, and the support cylinder includes an upper support cylinder 51 and a The lower support cylinder 52, there is a return channel 15 for the catalyst to fall between...

Embodiment 2

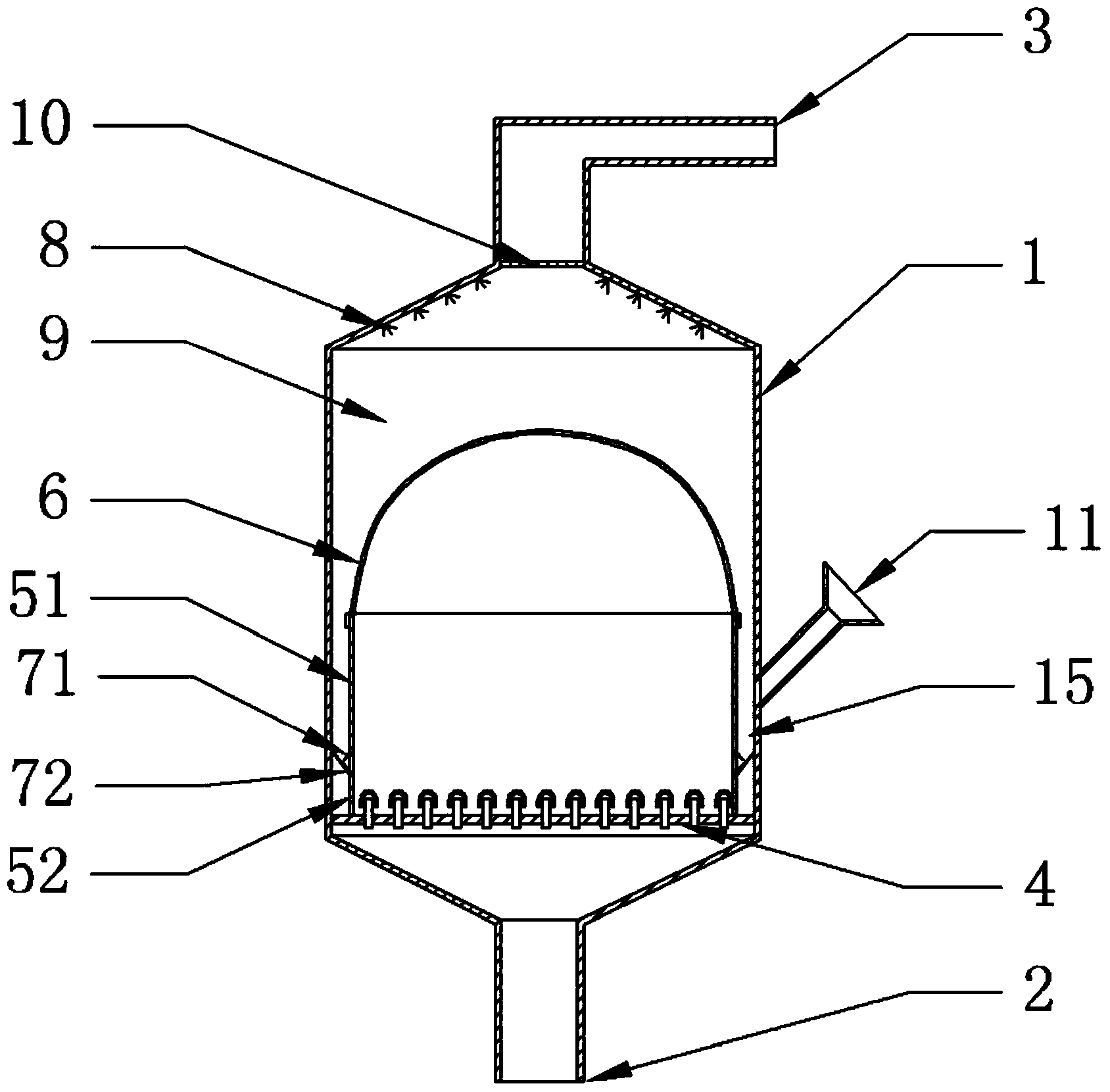

[0027] The circulating fluidized bed catalytic reduction method denitrification reactor of embodiment 2, such as figure 2 ,3 As shown, the difference from Example 1 is that a baffle plate 10 is provided at the place where the reactor inner chamber 9 communicates with the outlet flue 3, and the baffle plate 10 is a porous plate, and the aperture of the through hole on the baffle 10 is smaller than that of the filter container When the equipment is running, the catalyst removed from the fluidized bed rises with the flue gas, and is intercepted by the baffle plate and falls. The reactor shell 1 is provided with a feeding port 11 communicated with the reactor inner chamber 9, the feeding port 11 is located above the feeding port, during the operation of the equipment, the lost catalyst can be added through the feeding port 11, and the added The catalyst enters the return channel 15, and enters the filter container through the return port 7, so as to ensure that the amount of cata...

Embodiment 3

[0028] The circulating fluidized bed catalytic reduction method denitrification reactor of embodiment 3, such as Figure 4 As shown, the difference from Example 2 is that: the reactor inner cavity 9 is provided with a guide cover 16 above the filter container, the guide cover 16 is opened downward and has a middle part with the shielding plate 10. A cover structure with through holes arranged opposite to each other up and down. The cross section of the cover structure is in the shape of an "eight", and the lower edge of the guide cover 16 is located above the return channel 15. The inner surface of the guide cover 16 is provided with a denitration reactant adding device, and the denitrifying reactant adding device is an ammonia water nozzle 8 . The role of the guide cover 16 is to guide the catalyst intercepted by the baffle plate 10 or the inner wall of the reactor cavity 9 to the feed-back channel 15 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com