Environmental treatment automatic electric power station coal dust adsorption and cleaning protective wall

A technology for protective walls and power plants, which is applied in the direction of combined devices, buildings, and separation of dispersed particles. It can solve problems such as waste of water resources, air pollution, and unsuitable dust treatment, and achieve the effect of convenient installation and disassembly, and dust reduction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

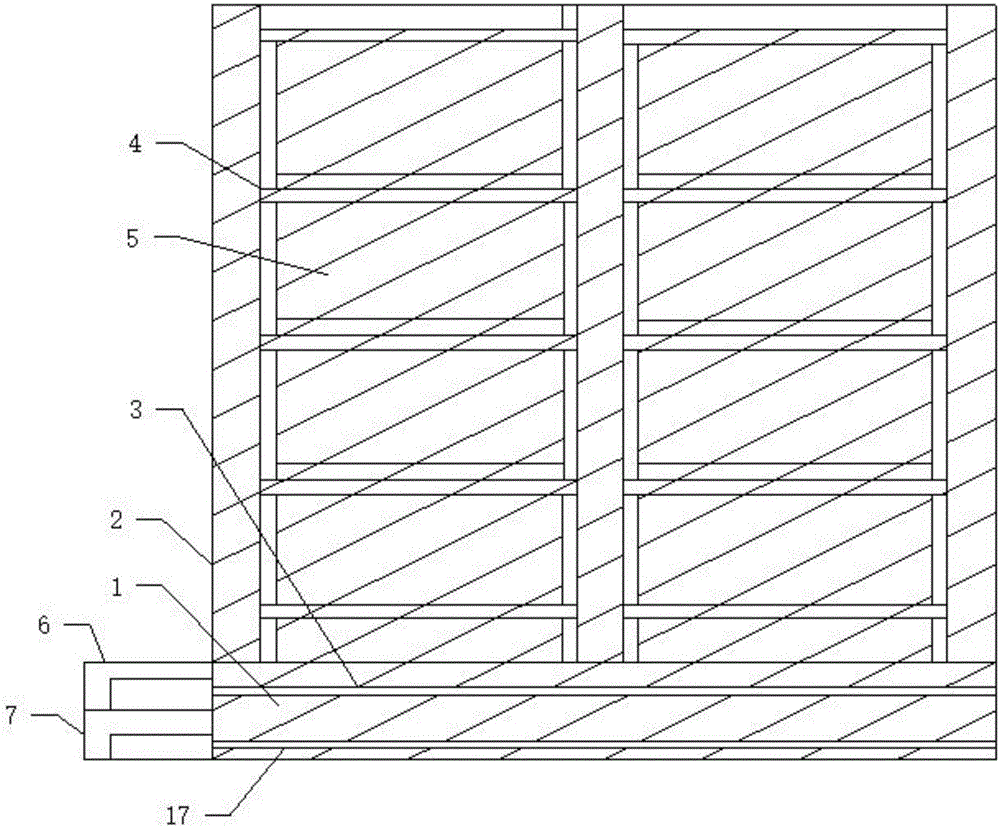

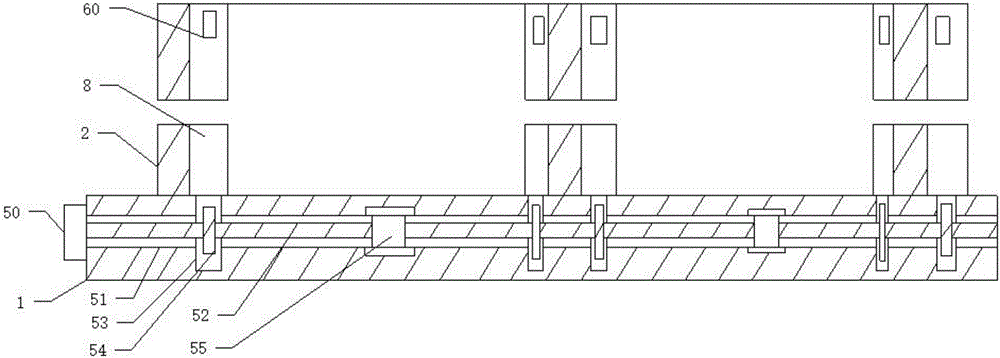

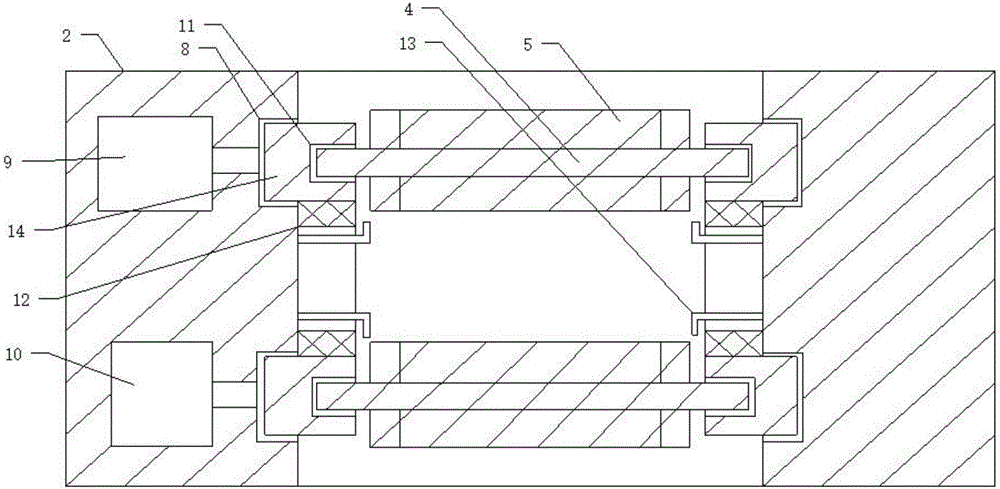

[0033] like Figure 1 to Figure 8 As shown, an environmental treatment power plant coal dust automatic adsorption protective wall protection wall includes a base 1, a row of protective support rods 2 are evenly connected to the base 1, and the two sides of the protective support rods 2 are respectively provided There is a rotating chain 12, a row of corresponding lifting blocks 14 are respectively connected on the chain 12, a fixed rod 4 is respectively connected between each adjacent two lifting blocks 14, and a fixed rod 4 is respectively provided on the fixed rod 4 Dust-proof filter screen 5, every two adjacent dust-proof filter screens 5 are correspondingly connected, and the base 1 can enclose the coal in the factory area, and a row of protective support rods 2 is connected on the base 1, so The number of the protective support rods 2 can be set according to the needs of the design, and the protective support rods 2 can be evenly connected to the base 1, and a rotating ch...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com