Cutter head driving device for shield tunneling machine and synchronous control method thereof

A cutter head drive and synchronous control technology, which is applied in earth-moving drilling, multiple motor speed adjustment, mining equipment, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0053] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

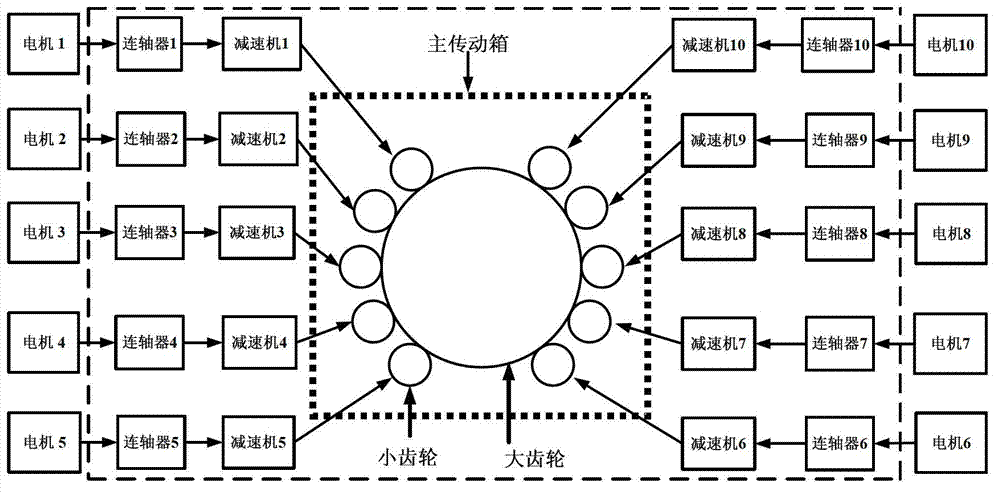

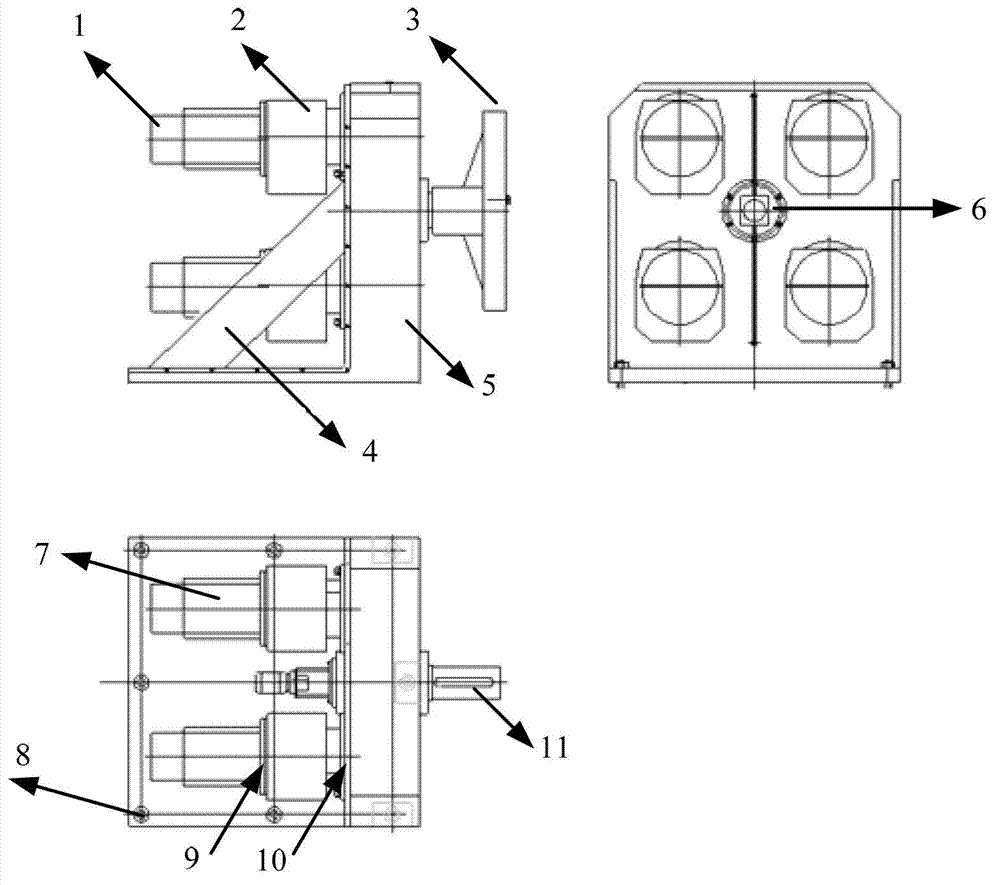

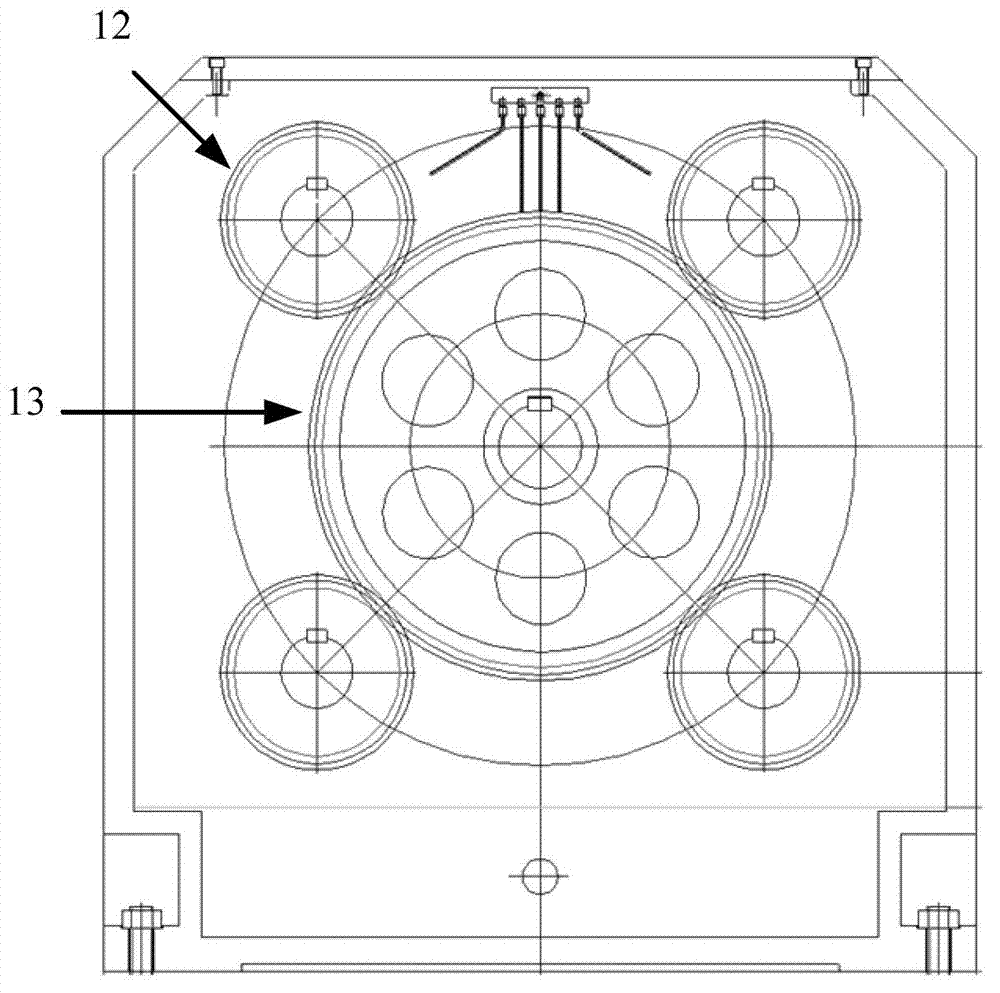

[0054] Aiming at the particularity of synchronous control of multi-motor output in the drive system of the shield tunneling machine and the practical problems faced by the drive system of the cutter head, a motor-driven drive structure of the cutter head of the shield tunneling machine and a principle drive device for the cutter head were invented and designed. , the invention proposes a parallel output synchronization control strategy with synchronization error compensation and an optimal MIMO PID controller design method with dynamic performance constraints, and the invention also proposes a weighted sliding mean synchronization error compensation method. The present invention proves the effectiveness of the present invention's device, output synchronous control strategy, synchronous controller design method and synchronous error compensation...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com