Open-air step blasting blasthole explosive energy homogenization device and charging method

A technology of step blasting and homogenization device, applied in blasting and other directions, can solve the problems of increased cost, construction volume, complicated operation, etc., and achieve the effect of improving the utilization rate of explosive energy, uniform rock crushing, and good homogenization effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

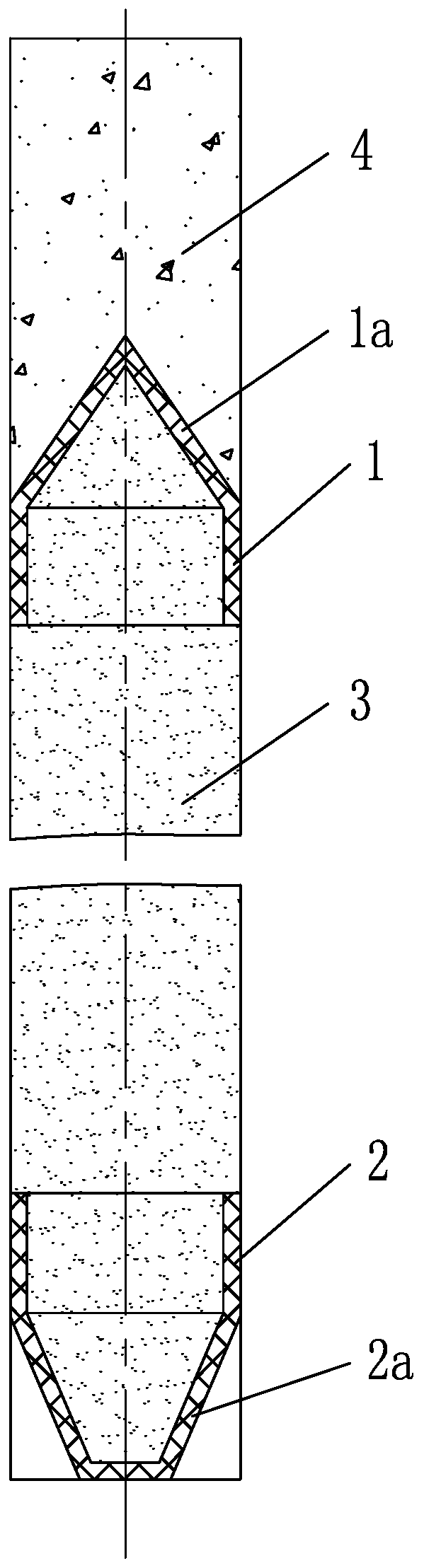

[0019] Example 1, see figure 1 , an open-air step blasting blasthole explosive energy homogenization device, comprising an upper explosive energy homogenization cylinder 1 and a lower energy homogenization cylinder 2 respectively arranged at the upper and lower ends of the blasthole charge section; the upper explosive energy homogenization cylinder 1 passes through the container The conical cover 1a of the structure constitutes the upper explosive energy homogenization structure, and the lower energy homogenization cylinder 2 constitutes the lower explosive energy homogenization structure through the conical frustum 2a of the container structure; the large ends of the conical cover 1a and the conical frustum 2a are facing each other set up.

[0020] Wherein, both the upper explosive energy homogenizing cylinder 1 and the lower energy homogenizing cylinder 2 are formed with circular guide cylinders, and the two circular guide cylinders respectively extend from corresponding tap...

Embodiment 2

[0021]Embodiment 2, a method for homogenizing the energy of blasthole explosives in open-air step blasting. The method is implemented based on the device in Embodiment 1. , so that the conical table tube 2a is filled with explosives to form the lower explosive energy homogenizing charge; after continuing to charge the charge to the set amount, buckle the upper explosive energy homogenizing cylinder 1 on the charge column with the tip of the cone facing upward, so that the charge The column forms a structure with taper at both ends, and the upper end has a conical spire, and the lower end is a truncated cone structure with the small end facing down; use the plugging material to block the blast hole and squeeze the upper explosive energy homogenizing cylinder 1 downward, so that the upper The conical cover 1a of the explosive energy homogenizing cylinder 1 is filled with explosives, thereby forming the upper explosive energy homogenizing charge and the dense plugging section 4 re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com