Efficient and direct curved surface numerical control machining method

A processing method and curved surface technology, which is applied in the field of high-efficiency curved surface direct numerical control processing, can solve the problem of no qualitative leap in processing efficiency, and achieve the effects of short processing time, improved processing efficiency and high precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The above and other technical features and advantages of the present invention will be described in more detail below in conjunction with the accompanying drawings.

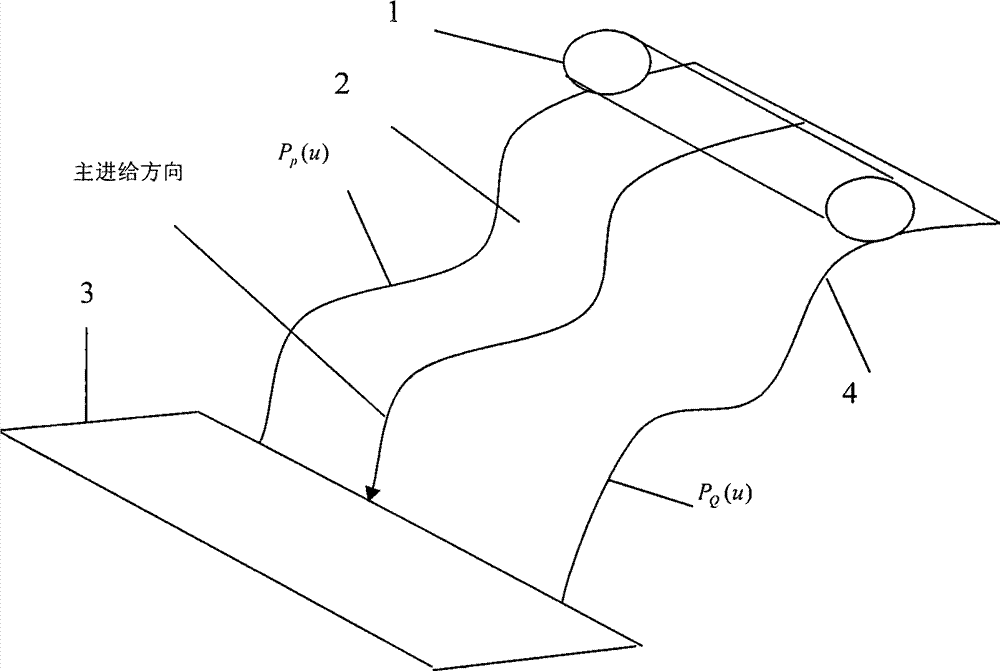

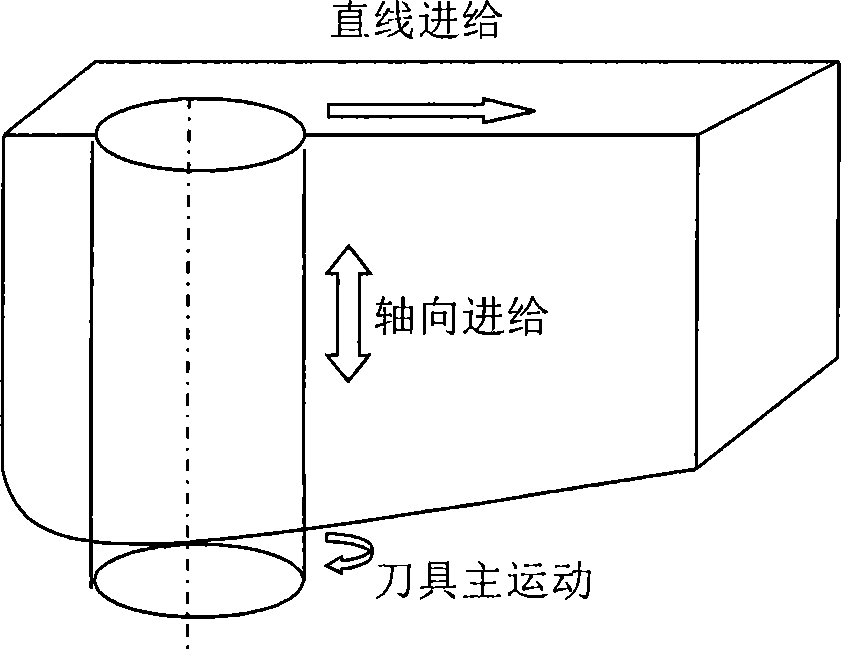

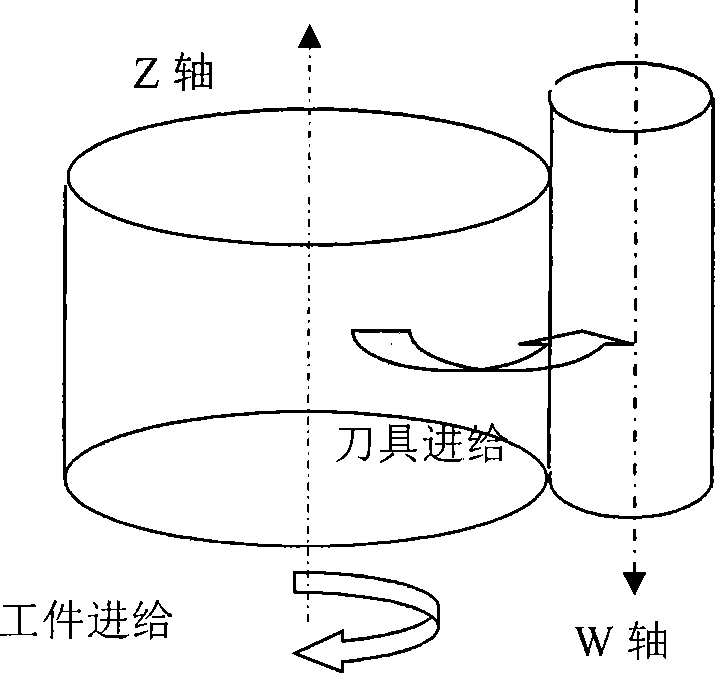

[0029] Realization of the present invention is as a kind of curved surface direct digital control processing method, and its concrete steps have:

[0030] Step a, write the NC machining code according to the surface features of the workpiece;

[0031] Step b, inputting the numerical control machining code of the space ruled surface of the workpiece into the numerical control system;

[0032] Step c, controlling the processing machine tool through the numerical control system to make the tool axis vector parallel to the vector of the starting line of the ruled surface;

[0033] Step d, controlling the rotation of the tool spindle;

[0034] Step e, adjusting the position of the workpiece or the tool so that the side edge of the tool is in tangential contact with the machining start line of the workpiece; ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com