Trial rod inverse plummet resisting control method

A control method and probe technology, applied in the field of probe anti-hammer control, can solve problems such as slow speed, calipers, and slow cloth time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

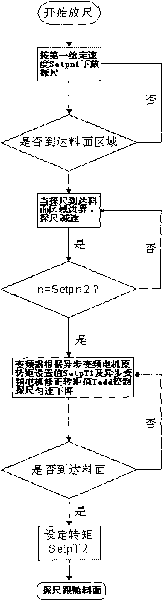

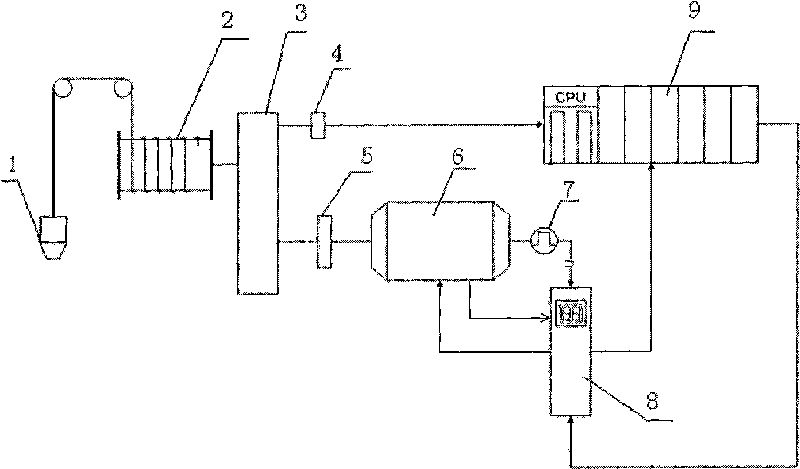

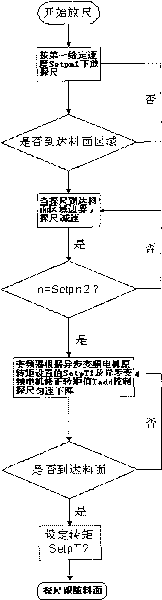

[0015] Such as figure 1 Shown, a kind of probe rod anti-down hammer control method, it comprises the following steps successively:

[0016] Step 1), first the roller drives the probe to drop at a constant speed at the first given speed;

[0017] Step 2), when the probe reaches the boundary of the material surface area, the PLC reads the signal that the probe reaches the boundary of the material surface area through the absolute encoder installed on the reducer, and then the PLC sends instructions to the inverter, and the inverter receives After the instruction, start to control the asynchronous frequency conversion motor to decelerate, the asynchronous frequency conversion motor drives the gear reducer and the roller to decelerate, and the roller drives the probe to decelerate;

[0018] Step 3), when the probe decelerates to the second given speed, the PLC calculates the corrected torque of the asynchronous variable frequency motor according to the read data, and then transmi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com