Rail vehicle truck parameter measuring table

A technology for parameter measurement and rail vehicles, applied in the direction of railway vehicle testing, measuring devices, torque measurement, etc., can solve the problems of inflexible horizontal movement and rotation, difficult measurement of various force values, failure to use normally, etc., to achieve The effect of flexible movement and rotation, easy manufacturing and processing, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

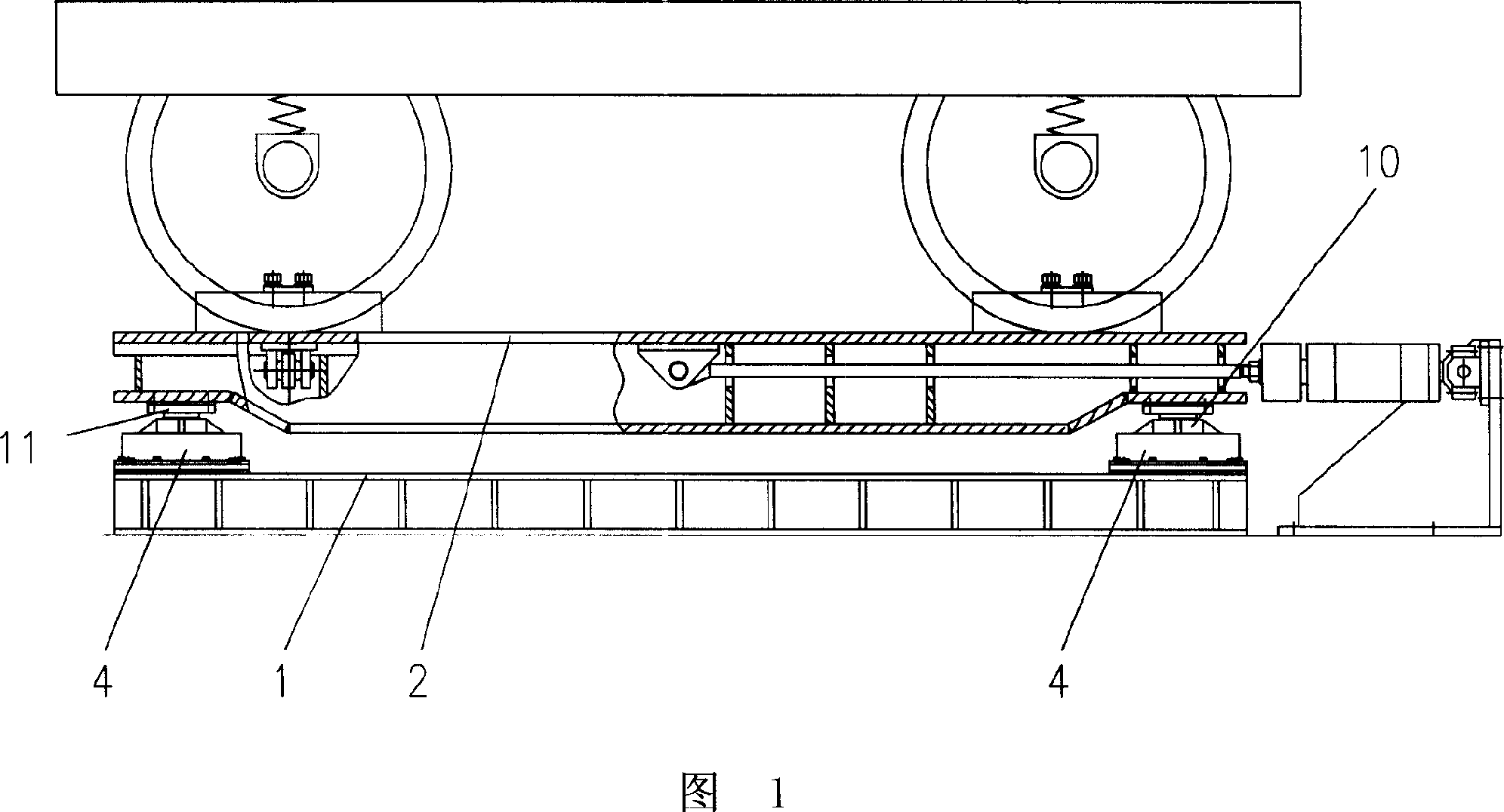

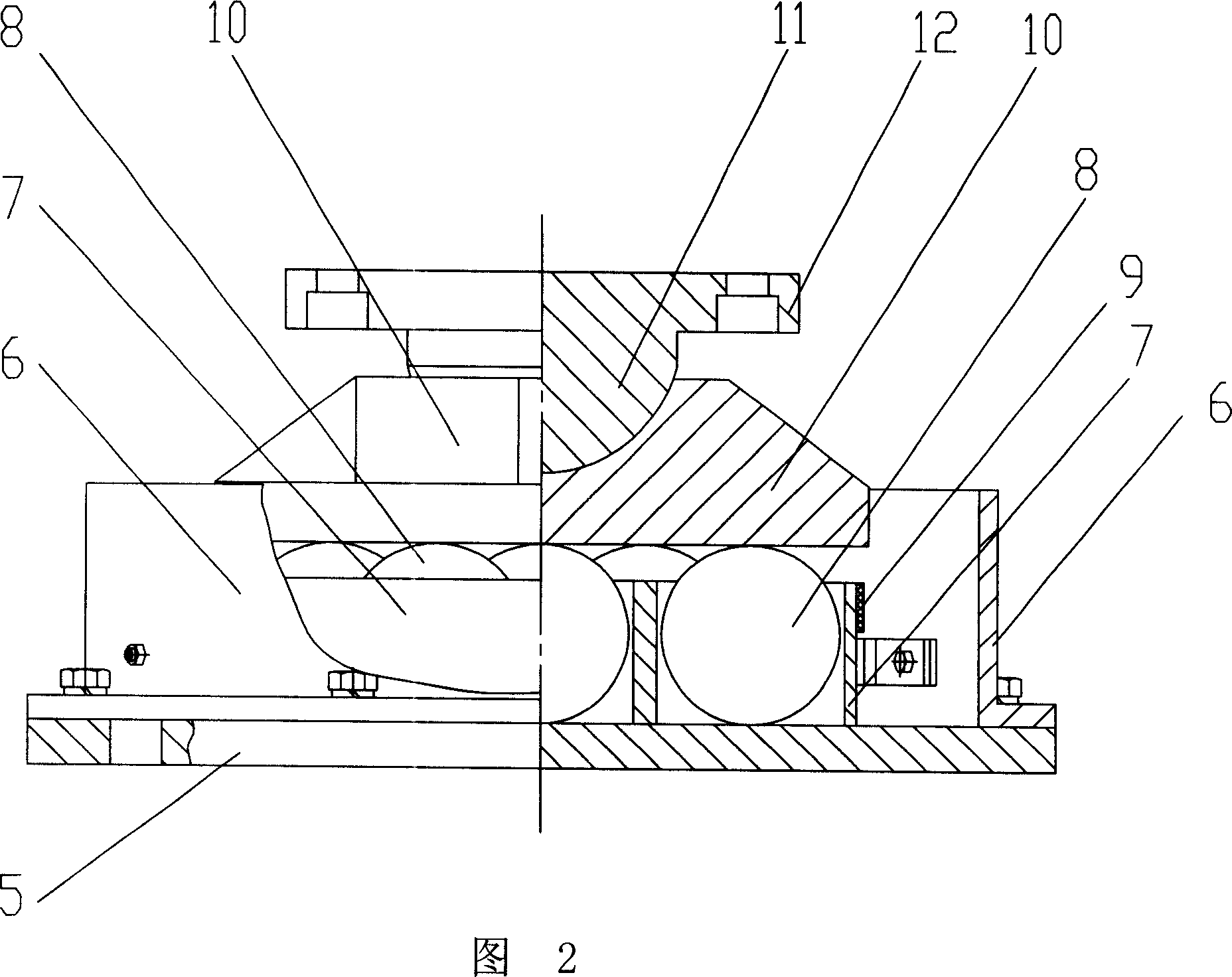

[0023] Fig. 1, 2, 3 show that a kind of embodiment of the present invention is:

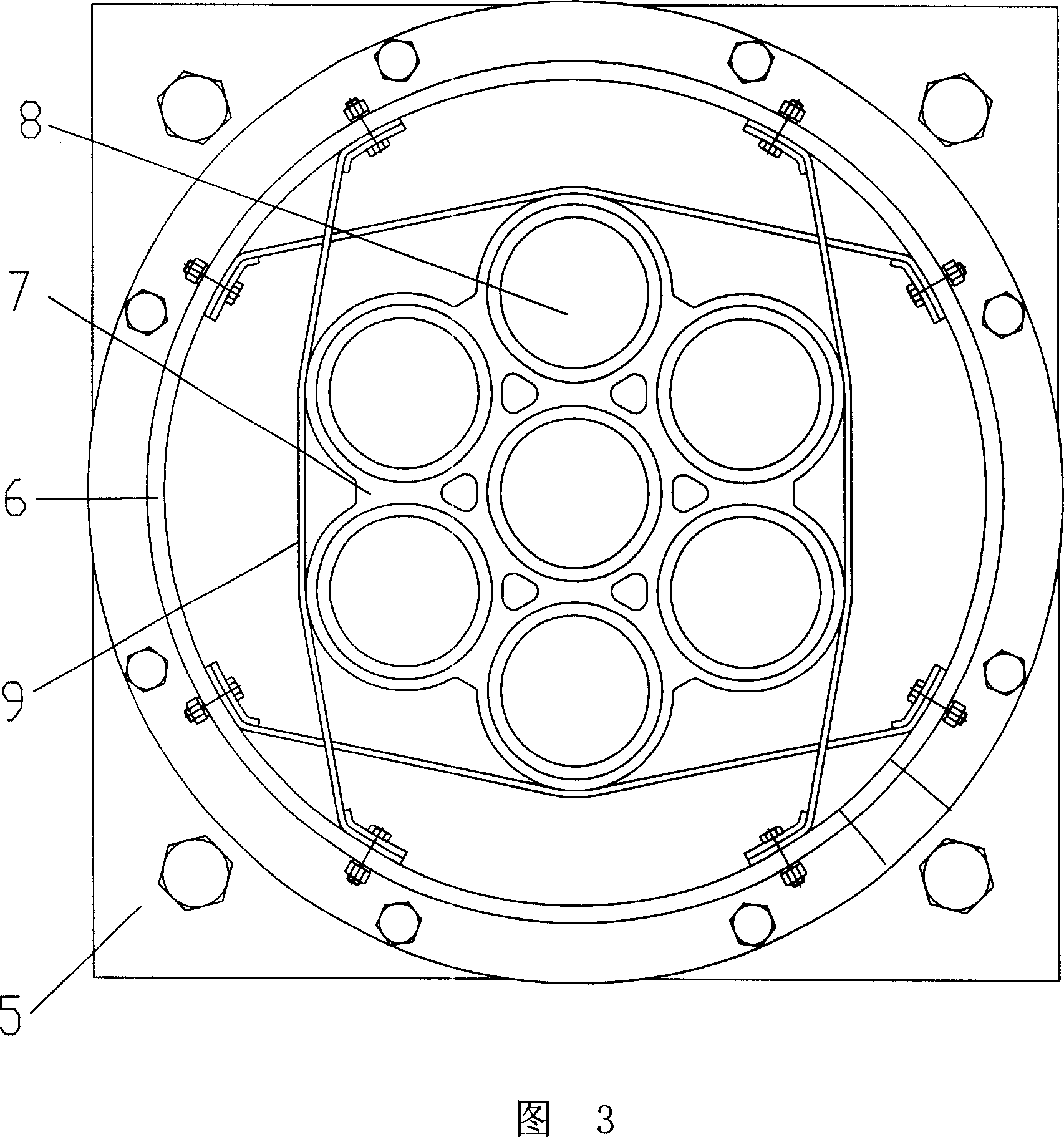

[0024] A rail vehicle bogie parameter measurement platform, comprising a base 1 and a measurement platform 2 above the base, the base 1 is connected to the measurement platform 2 through a floating support seat 4 at the corner, and the specific connection of the floating support seat 4 is: the corner of the base 1 A support base plate 5 is fixed at the top of the support base plate 5, and a limit ring 6 is provided on or near the edge of the upper part of the support base plate 5. A steel ball cage 7 is placed on the support base plate 5 in the limit ring 6, and a steel ball cage 7 is placed in the steel ball cavity of the steel ball cage 7. Steel ball 8 is placed in it.

[0025] Figures 2 and 3 show that the four return rubber bands 9 whose ends are fixed on the limit ring 6 enclose the steel ball cage 7 in the middle of the support plate; the steel balls in the steel ball cavity of the steel ba...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com