Ladle overturning and dumping machine

A technology of ladle and dumping machine, which is applied in the direction of casting melt containers, metal processing equipment, casting equipment, etc., can solve the problems of not adapting to the development of modern industry, poor operation safety, and low production efficiency, so as to reduce the labor intensity of workers, High production efficiency and the effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

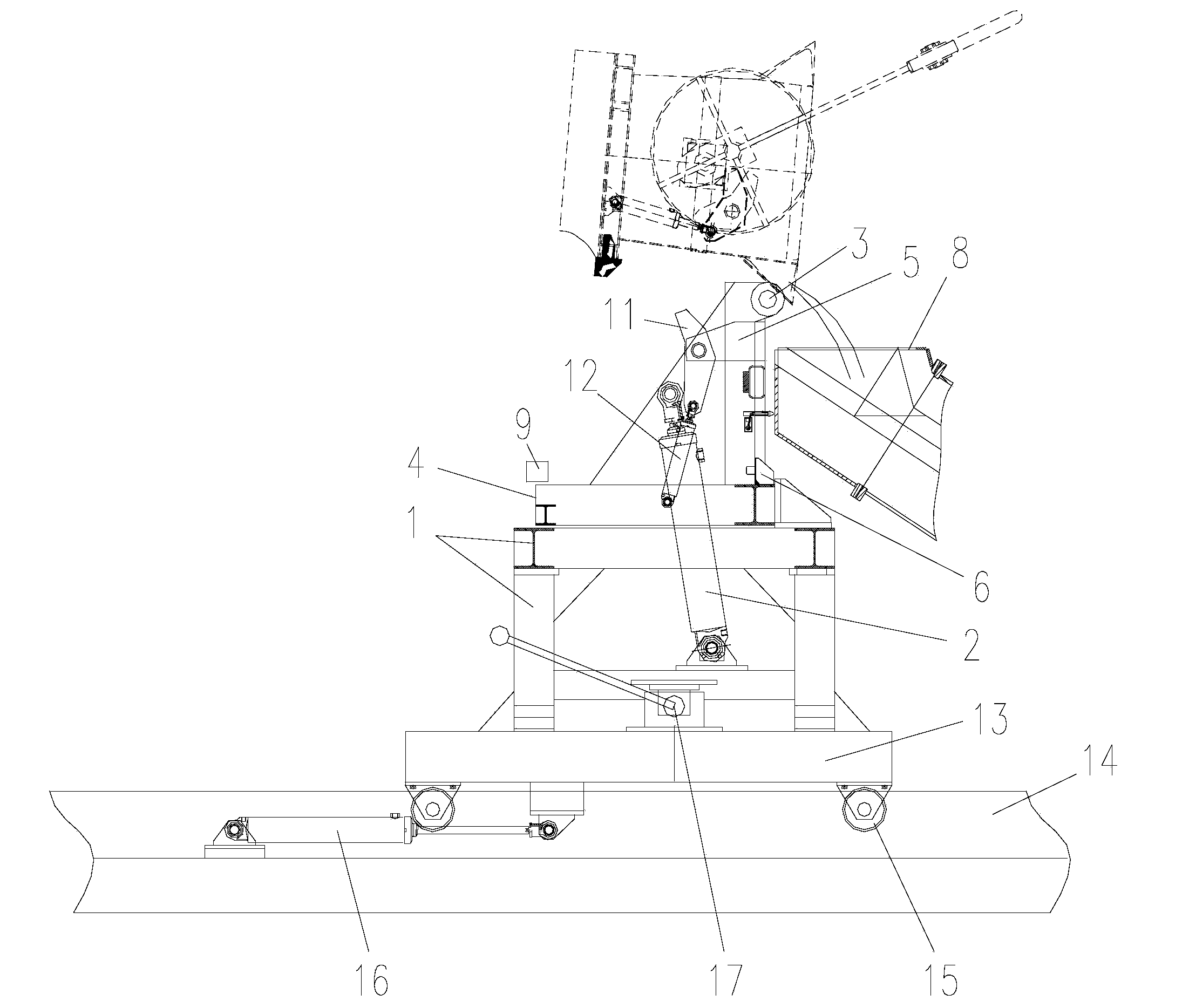

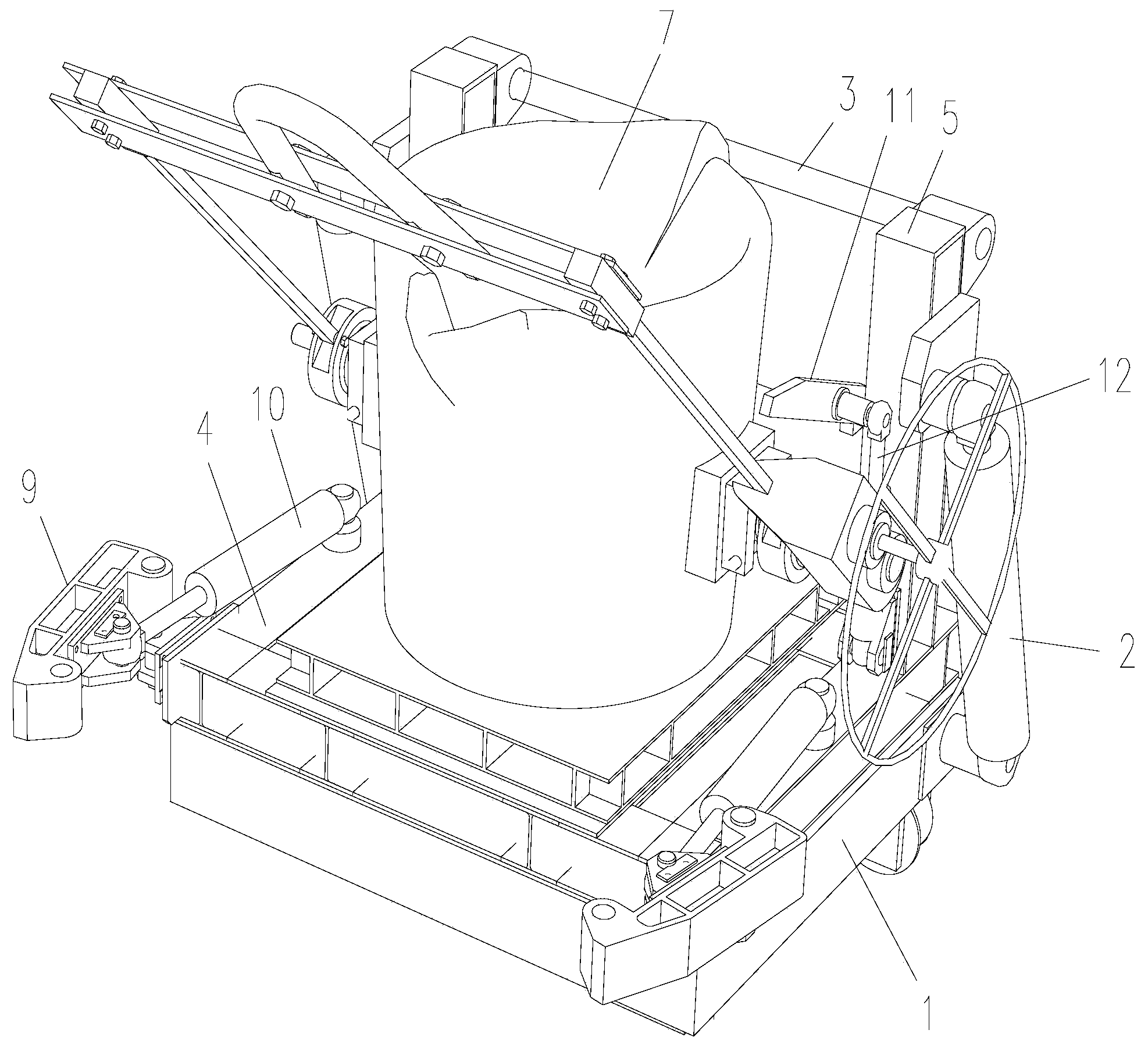

[0022] As shown in the figure, the molten iron ladle turning and dumping machine in this embodiment includes a workbench 1, a turning drive cylinder 2, a turning center axis 3 arranged horizontally, a turning base 4 placed on the workbench 1, fixed on the workbench 1 and The shaft bracket connected to the overturning central axis 3 (the axis bracket is not shown in the figure) and the overturning frame 5 connecting the overturning central axis 3 and the overturning base 4, one end of the overturning drive cylinder 2 is hinged on the workbench 1, and the other end Hinged on the reversing frame 5, the reversing base 4 is provided with a ladle stopper 6, a horizontal pressing mechanism that compresses the ladle 7 on the ladle stopper 6 in the horizontal direction and presses the ladle 7 tightly The vertical pressing mechanism on the flip base 4.

[0023] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com