Comprehensive testing device and method for rudder pedal force and angle in control cabin

A technology for testing device and pedal force, which is applied to measuring device, measuring force applied to control element, instrument, etc., can solve the problems of inapplicability to the assembly workshop, inconvenient installation, large error, etc., and reduce the difficulty of operation and labor. Strength, meet the needs of functional debugging, avoid the effect of human error

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The making and using of specific embodiments are discussed in detail below. It should be understood, however, that the specific embodiments discussed are merely illustrative of specific ways to make and use the invention and do not limit the scope of the invention.

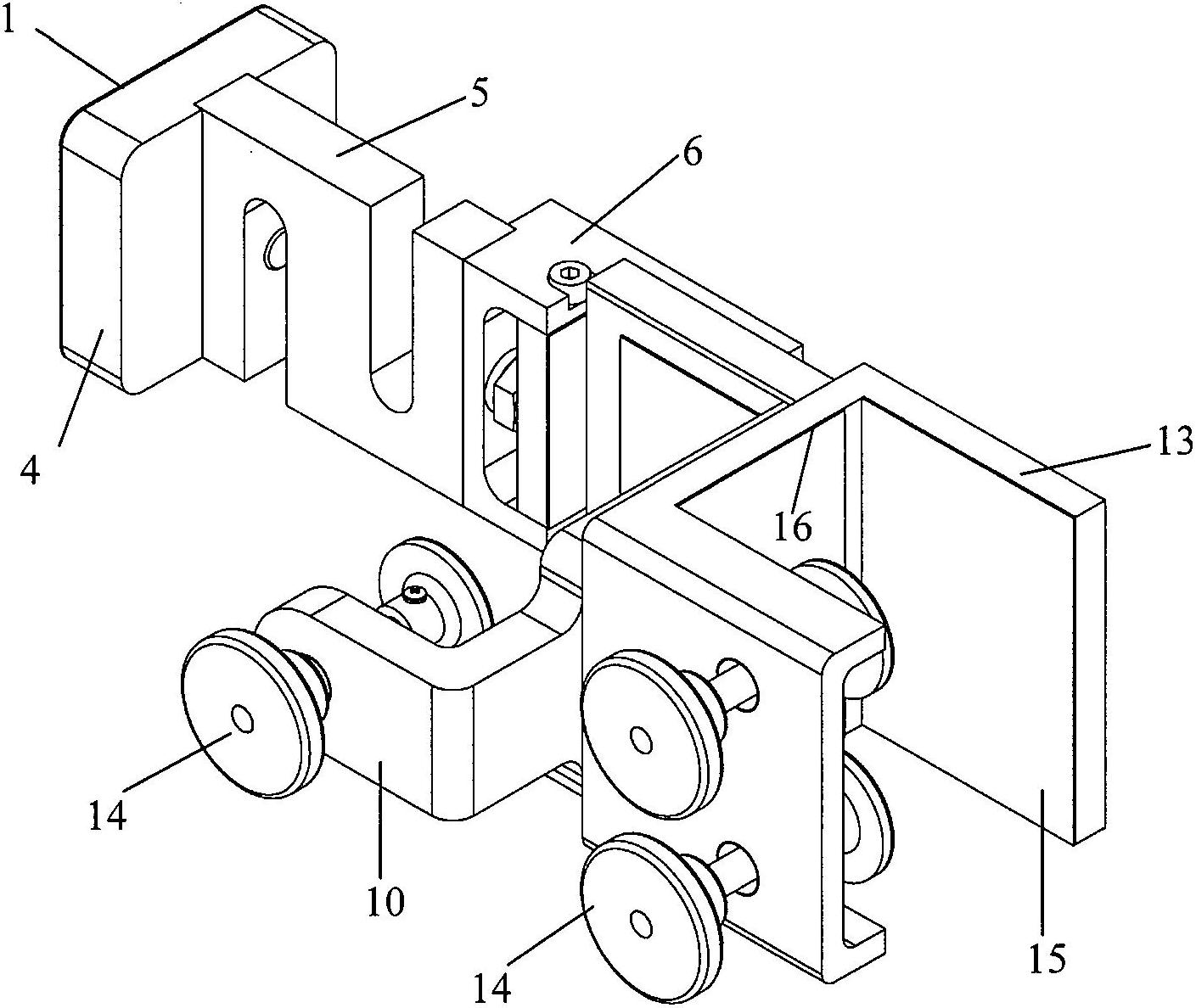

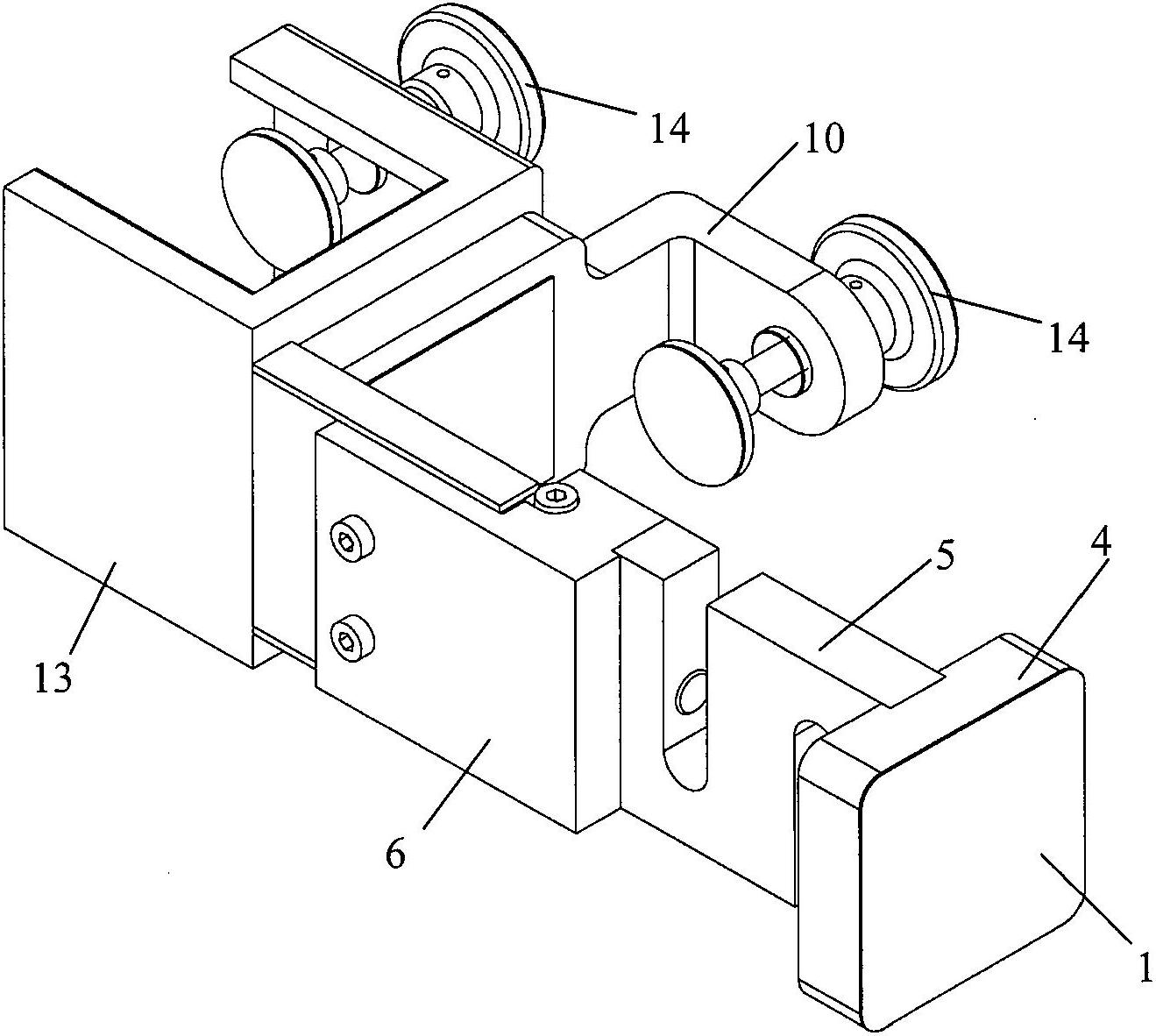

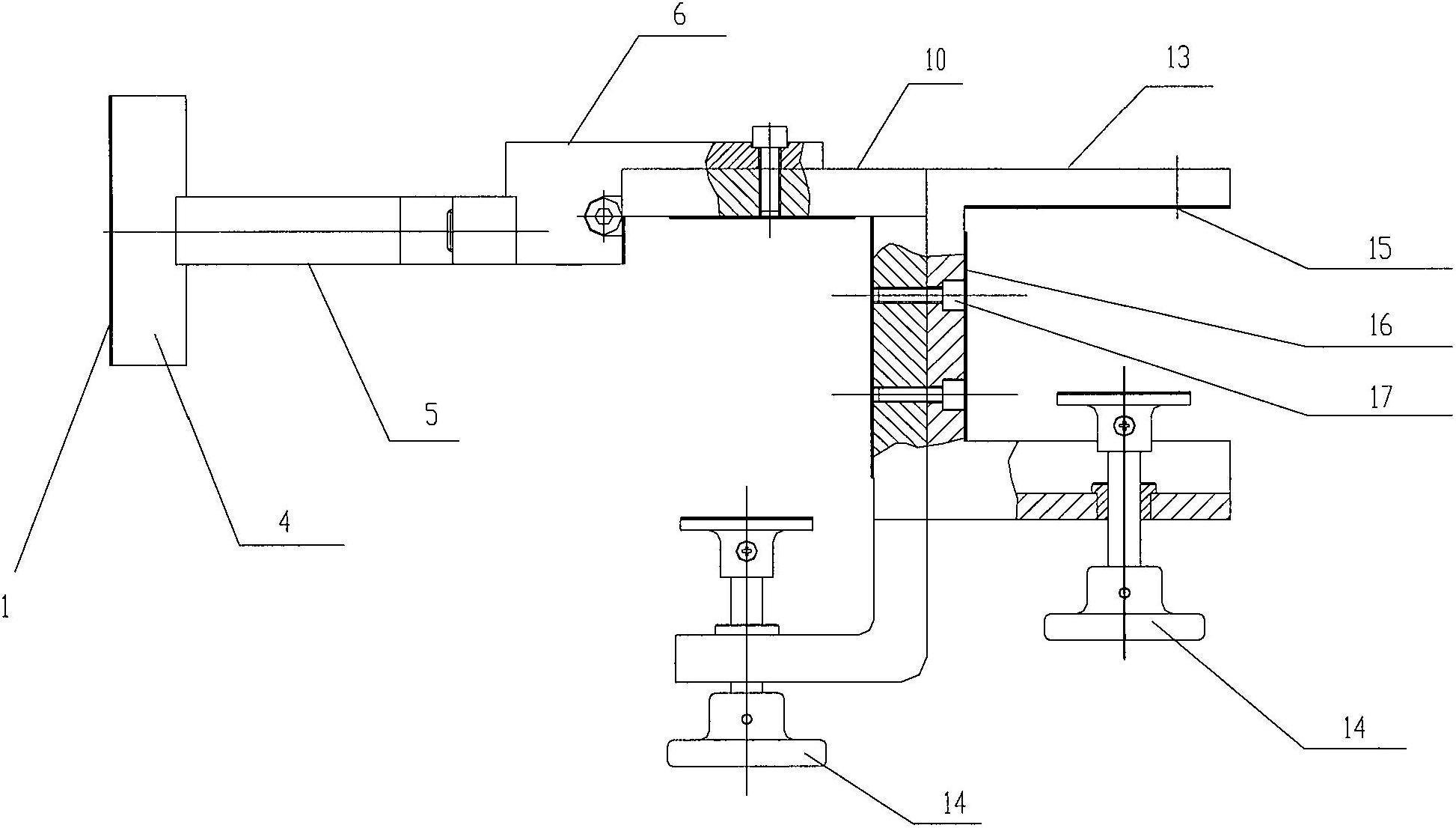

[0023] figure 1 and figure 2 Respectively show perspective views viewed from different angles according to the test device of the cockpit rudder pedal force and angle according to the preferred embodiment of the present invention, image 3 and Figure 4 is the corresponding schematic plan view, in which the connecting parts for the fixed connection are shown in section. combine Figure 1 to Figure 4 , the test device consists of mounting on the rudder pedal column ( Figure 5 21) the upper part of the test fixture body, in the embodiment shown, the test fixture body is a split structure, including the first fixture 10 and the second fixture 13 fixedly connected together by screws 17, for example. The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com