Automatic spraying curing device for concrete bridge pier and use method

An automatic spraying and concrete technology, which is applied in the direction of bridges, bridge construction, erection/assembly of bridges, etc., can solve the problems of affecting the structural strength, safety and normal use, labor intensity of workers, and reducing the service life of bridge piers, so as to achieve environmental protection and The effect of maintenance is remarkable, the time of artificial high-altitude operation is reduced, and the operation efficiency is high

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be described in further detail below through the embodiments and accompanying drawings.

[0014] The technical scheme adopted by the concrete pier automatic spray maintenance device of the present invention is:

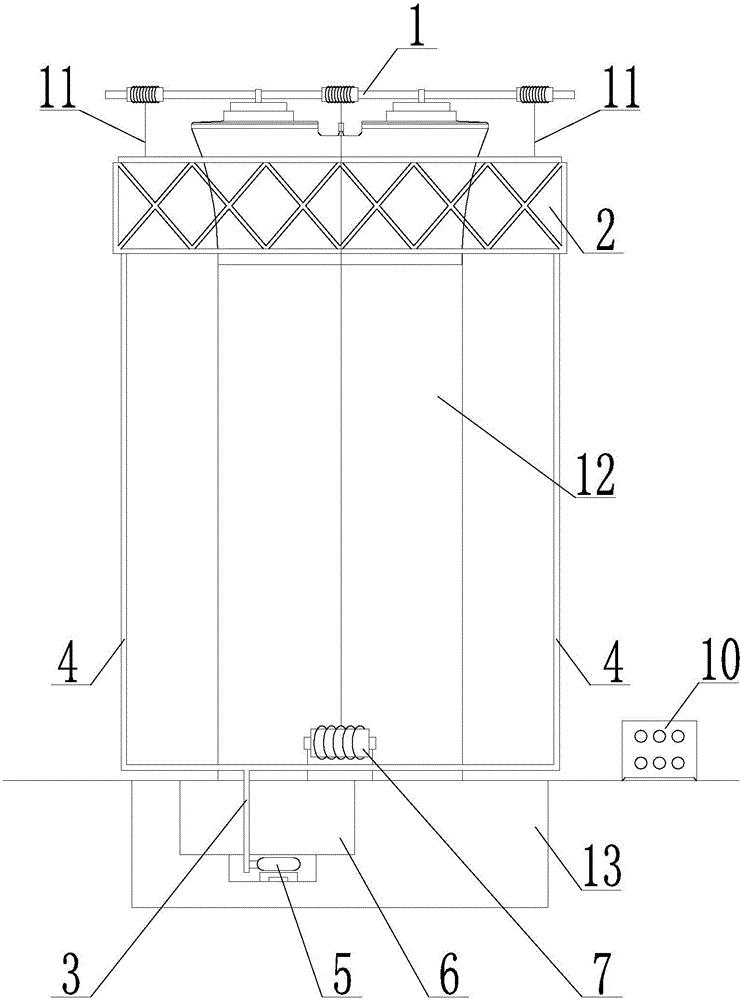

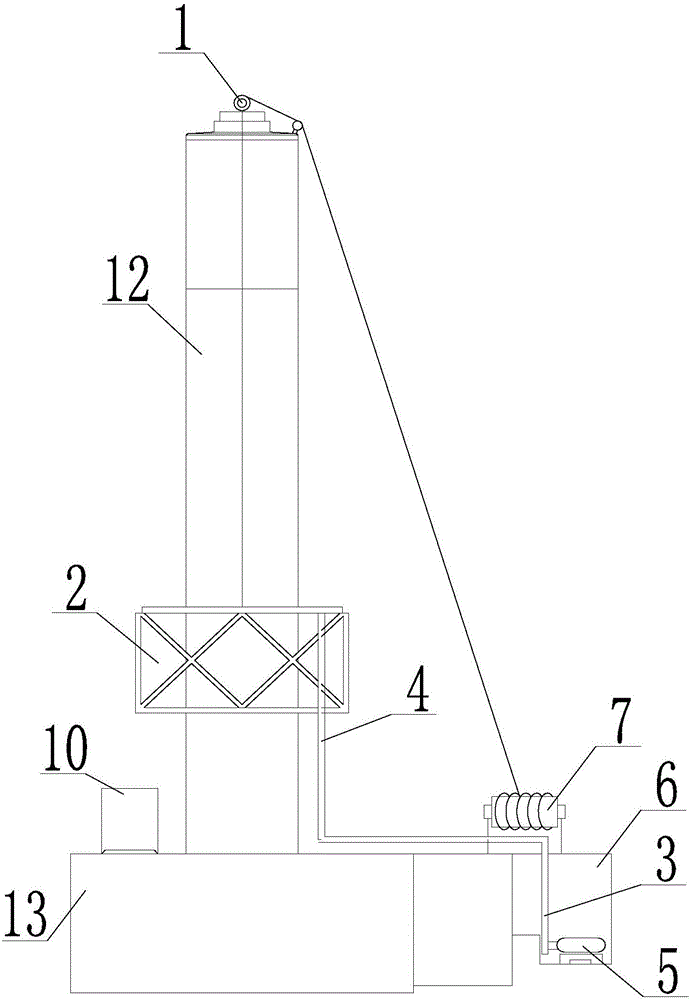

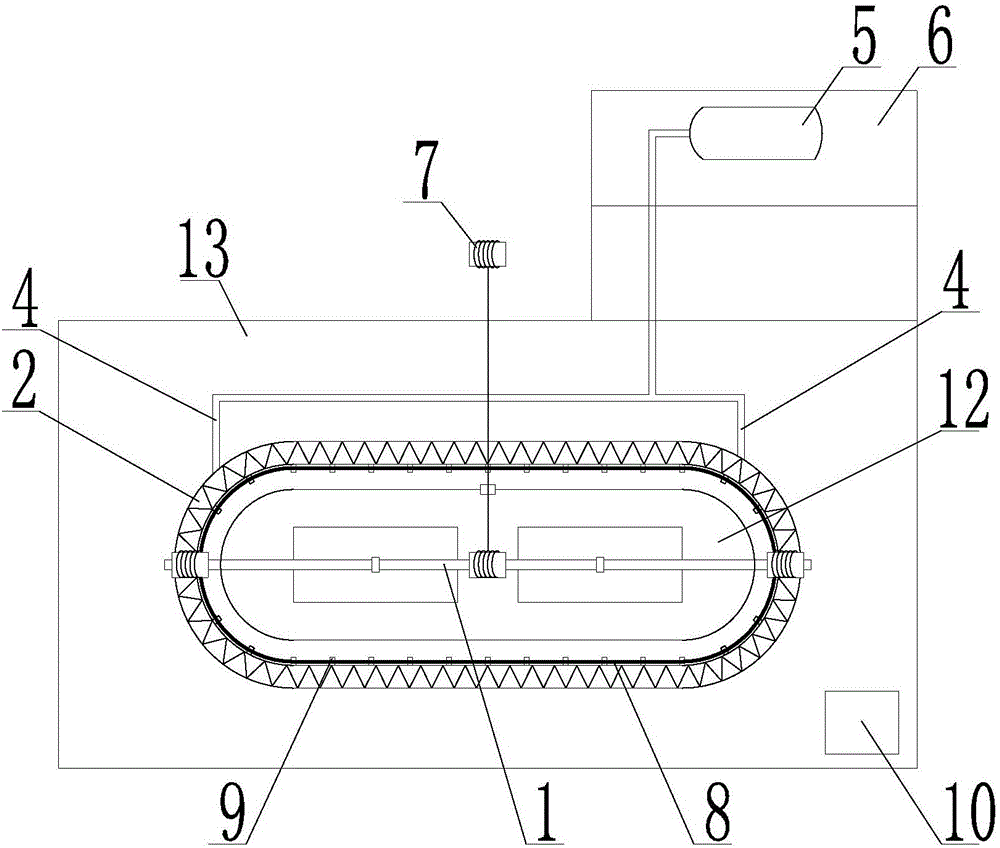

[0015] like figure 1 As shown, the hoisting system is composed of a winch 7, a rotating shaft 1, and a lifting wire rope 11. The rotating shaft 1 is hinged on the top of the pier 12, and the wire rope on the hoisting machine 7 is wound in the middle of the rotating shaft 1. The lifting wire ropes 11 wound at both ends of the rotating shaft 1 are respectively connected to On the spray maintenance frame 2; the water supply system is composed of a water supply tank 6, a water pump 5, a main water delivery pipe 3, and a water delivery pipe 4. One end of the water delivery pipe 4 is connected with the water delivery pipe 4, and the water delivery pipe 4 is placed on both sides of the concrete pier 12; the spray system is composed of the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com