Machine tool for flattening wall space

A flat machine, plane technology, applied in the direction of construction, building structure, etc., can solve the problems of difficult to meet the construction, lack of raw materials, and increased load bearing load of buildings, so as to save decoration materials and labor, low operating labor intensity, Effect of reducing building load

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

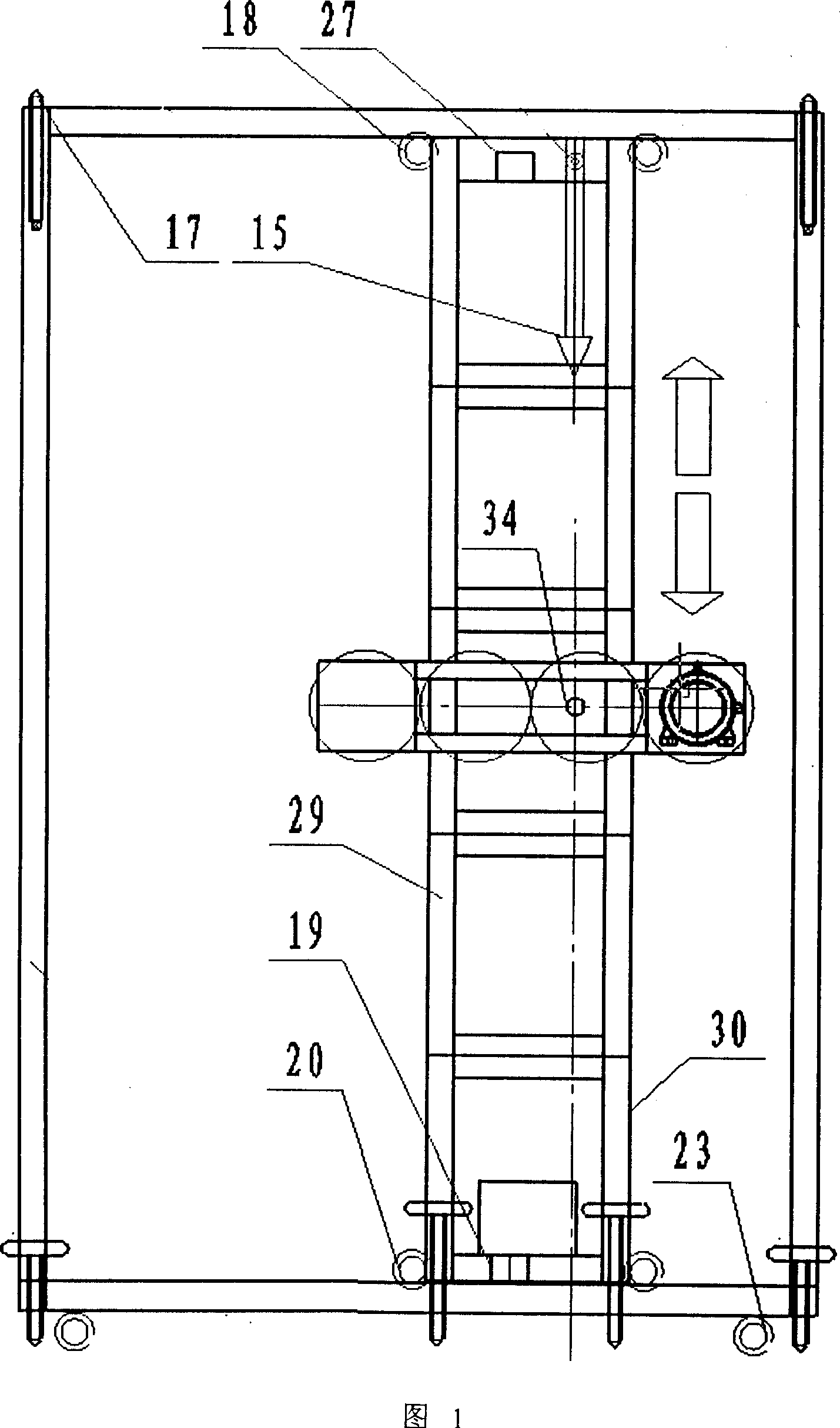

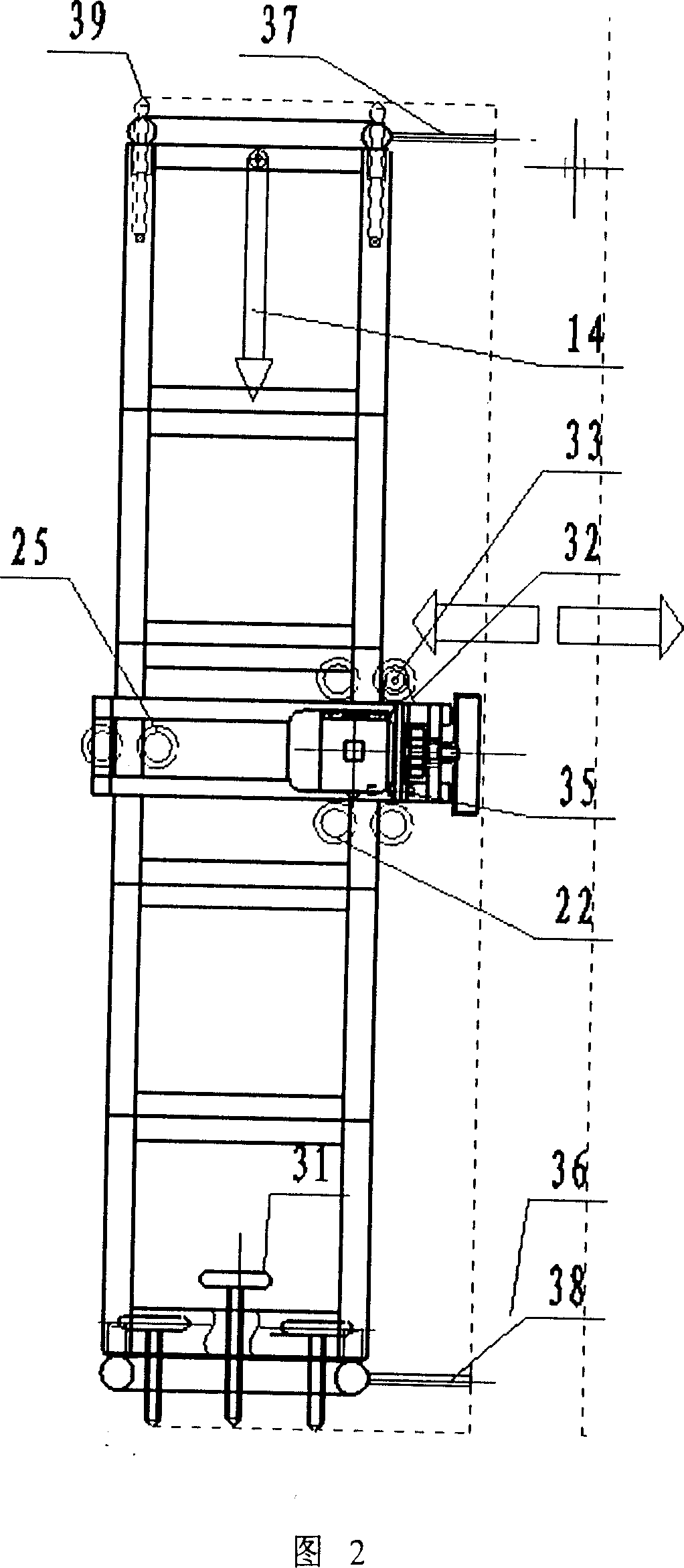

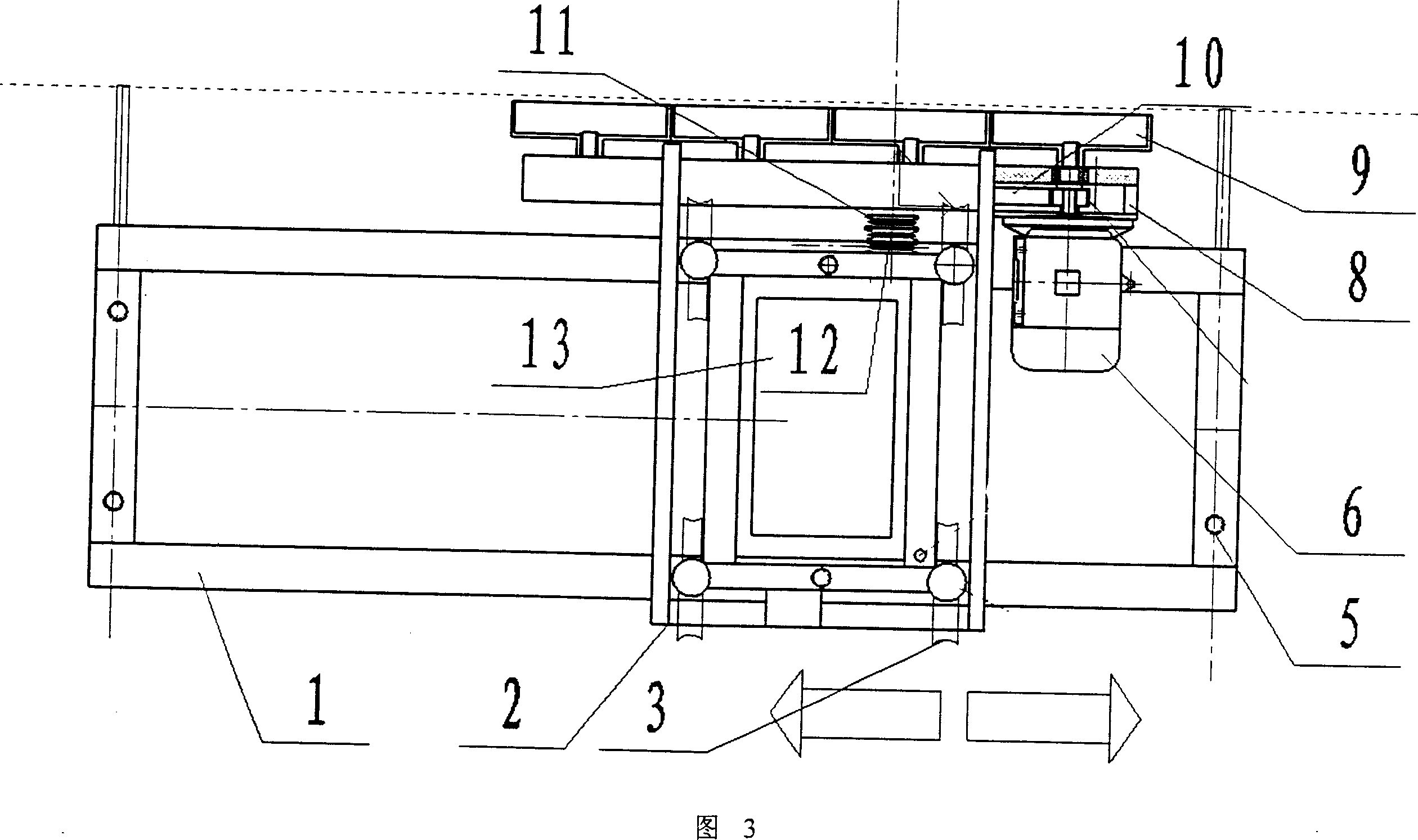

[0024] The wall leveling machine of the present invention will be described in detail below with reference to the embodiments.

[0025] The wall leveling machine of the present invention is designed to solve the problems of slow construction speed, large amount of materials, and difficulty in meeting the national requirements for wall finishing in building construction. It is a device for quickly and efficiently leveling the rough wall surface. The method of removing material from the uneven part of the rough wall surface uses the lifting mechanism, the horizontal moving mechanism, the horizontal and vertical positioning mechanism, the power milling cutter head that can change the direction, and the movable and rotating linear positioning mechanism to repair and level the wall surface, achieving reduction The number of times of decoration, the thickness, the saving of decoration materials and labor, and the purpose of reducing the construction load.

[0026] With reference to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com