Table top five-freedom-degree microminiature combined machining machine tool

A compound processing and micro-miniature technology, which is applied in metal processing, metal processing equipment, manufacturing tools, etc., can solve the problems of poor precision of micro-miniature parts, increase the cumulative error of clamping, and low processing efficiency, so as to reduce manufacturing energy consumption and cost, improve processing accuracy, and improve the effect of processing quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0064] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments, but the present invention is not limited to these embodiments.

[0065] For the convenience of description, the length direction of the workbench is defined as the X-axis direction, the width direction of the workbench is defined as the Y-axis direction, and the height direction of the workbench is defined as the Z-axis direction.

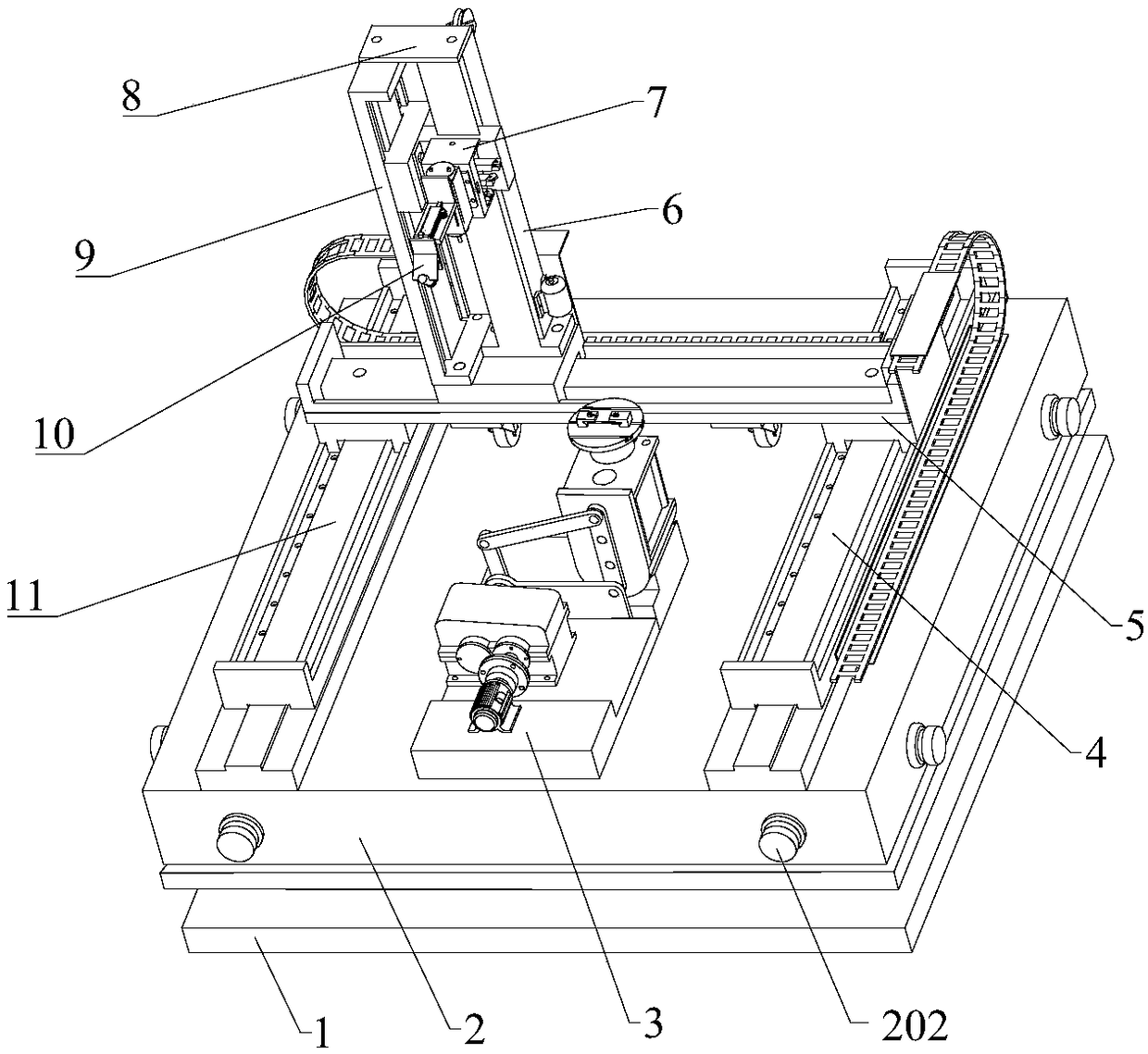

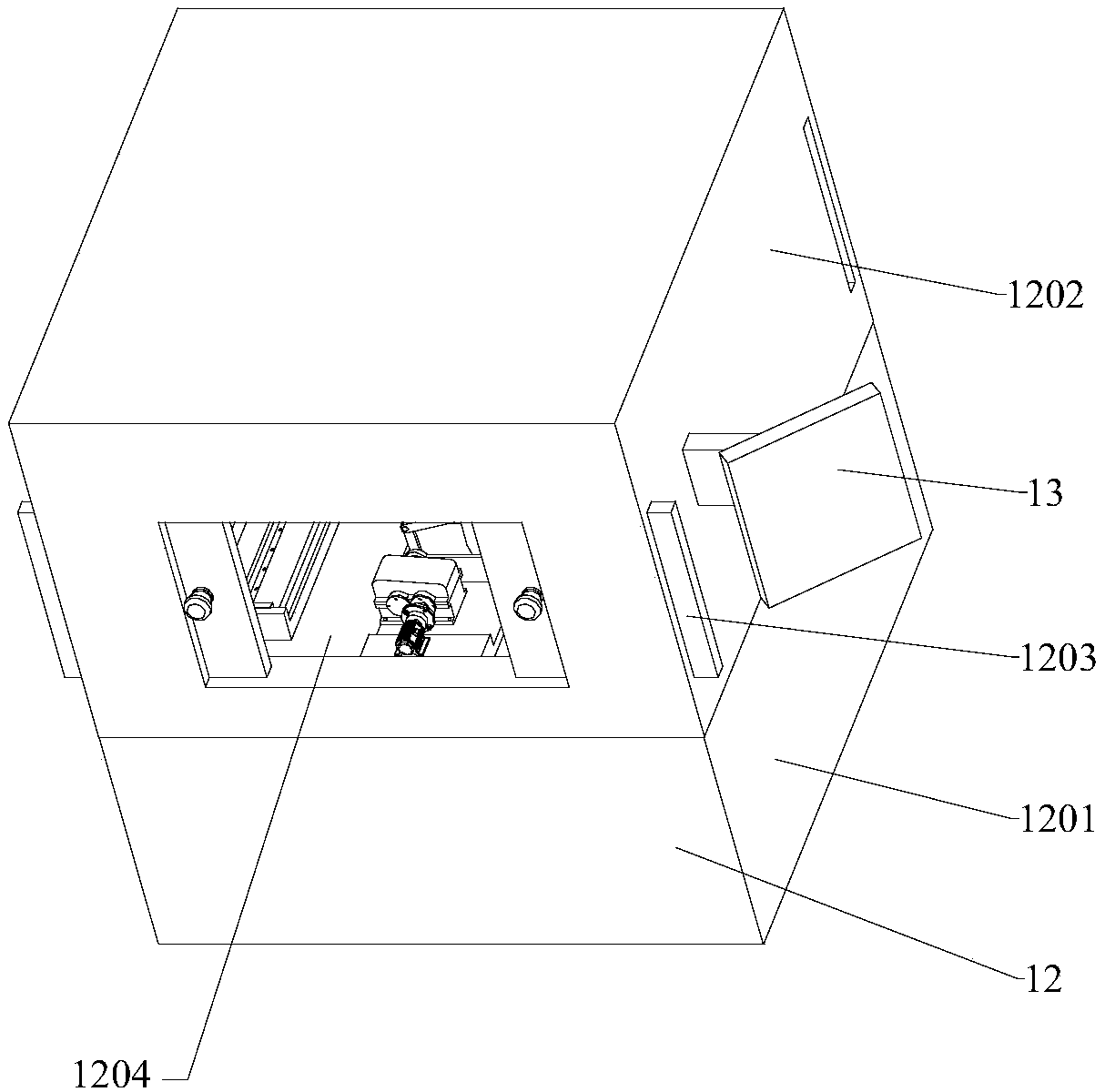

[0066] Such as Figure 1 to Figure 30 As shown, a desktop five-degree-of-freedom micro-compound processing machine tool includes a box body 12, and the box body 12 includes an upper box body 1202 and a lower box body 1203, and the front and rear sides of the upper box body 1202 are provided with viewing windows 1204 Each viewing window 1204 is respectively provided with a sliding door 1203 to open or close the viewing window 1204 .

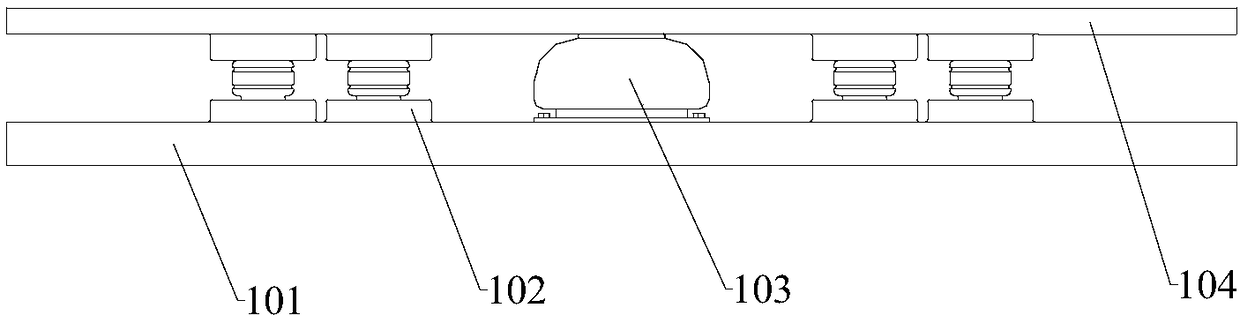

[0067] The processing machine tool also includes a workbench base module 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com