Folding-fan-type cell cover plate of aluminum electrolytic cell

An aluminum electrolytic cell and fan-folding technology, which is applied to the cover plate of the fan-type aluminum electrolytic cell and the field of non-ferrous metal smelting, can solve the problems of high labor intensity, large amount of material used for the cover plate, deformation and damage of the cover plate, etc., and achieve Good thermal insulation effect, low operating labor intensity, and excellent airtight performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The following describes the implementation of the present invention in detail with reference to the drawings and embodiments.

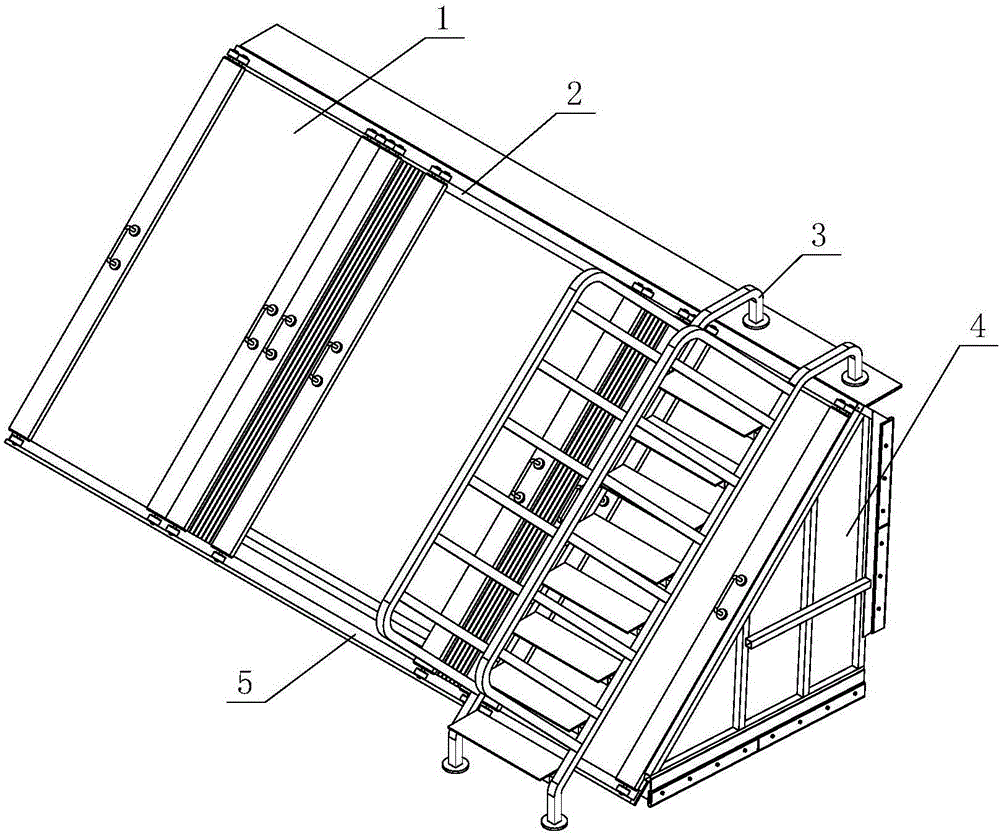

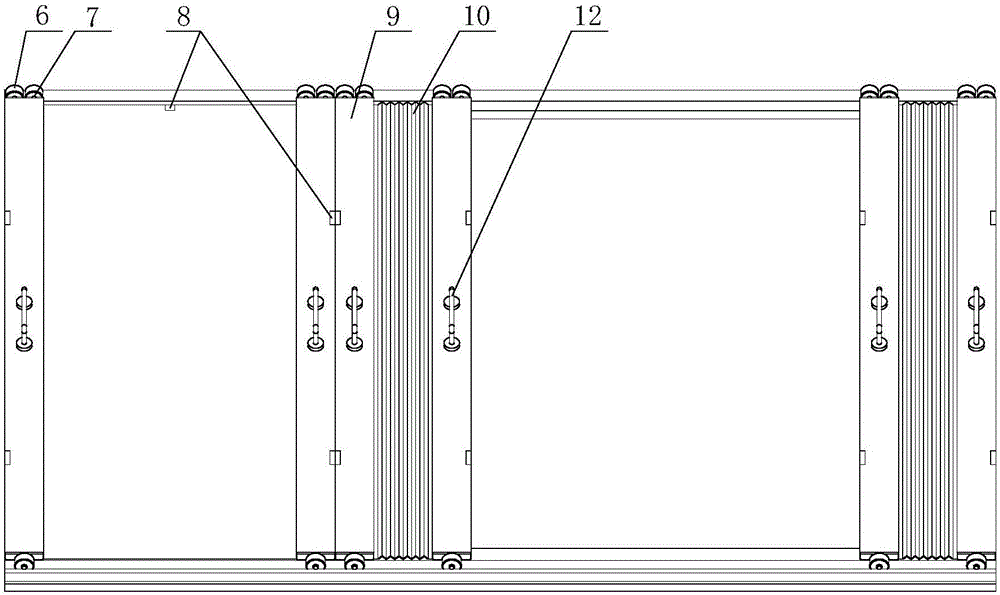

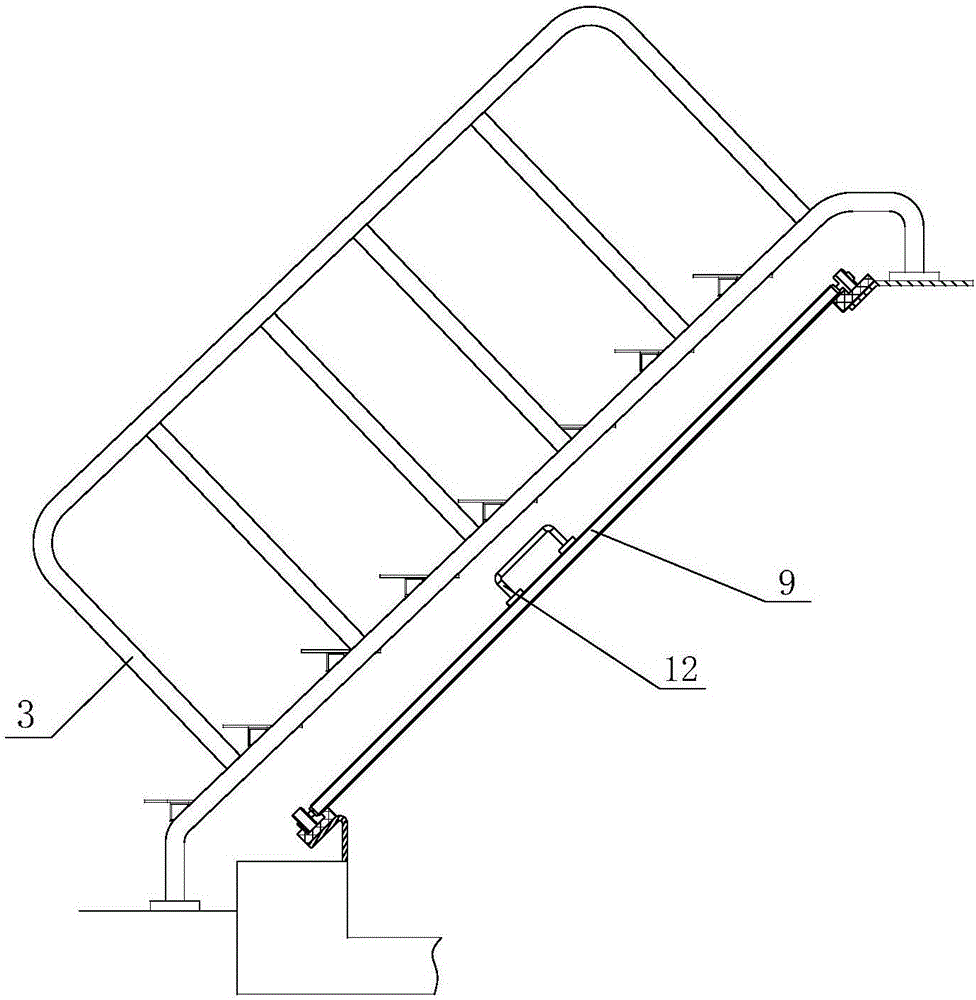

[0026] The present invention is a folding fan type aluminum electrolytic cell tank cover plate, which is mainly composed of a large surface tank cover 1, an upper rail 2, a climbing ladder 3, a corner tank cover 4, a lower rail 5 and the like. Among them, the large surface trough cover 1 is composed of a roller 6, a fixed shaft 7, a powerful magnet 8, an aluminum square tube 9, a folding fan structure 10, a thermal insulation coating 11, a handle 12, and the like. Such as figure 1 , 2 , 3, 4, 5, 6, 7, where figure 1 Is an elevation view, figure 2 Is a top view, image 3 Is a sectional view, Figure 4 with Figure 5 Is a partial enlarged view, Image 6 Is a three-dimensional diagram of the closed state, Figure 7 It is a three-dimensional image of the open state.

[0027] The large-face groove cover 1 uses aluminum square tubes 9 at the two sides o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com